Thanks to the new online tool, profile technology and the corresponding connection processing can be ordered more easily and much more efficiently – from anywhere.

Development work on the item Machining Tool centred on a problem that has existed ever since aluminium construction profiles were invented: How do you combine the processes of specifying, documenting and ordering profiles and machining services in one single process?

In the past, customers first had to create complex drawings by hand or correctly describe cryptic codes or supposedly self-explanatory article numbers. Profile technology suppliers were then tasked with deciphering this information and converting it into bills of material for production. Alternatively, profiles and machining services could also be lodged in the CAD system, but that didn’t really save a lot of time. All in all, putting together all the documentation, first for the customer enquiry and then for production, was a complex task and nobody could afford to make a mistake at any point in this manual process.

Choosing the perfect aluminium profiles

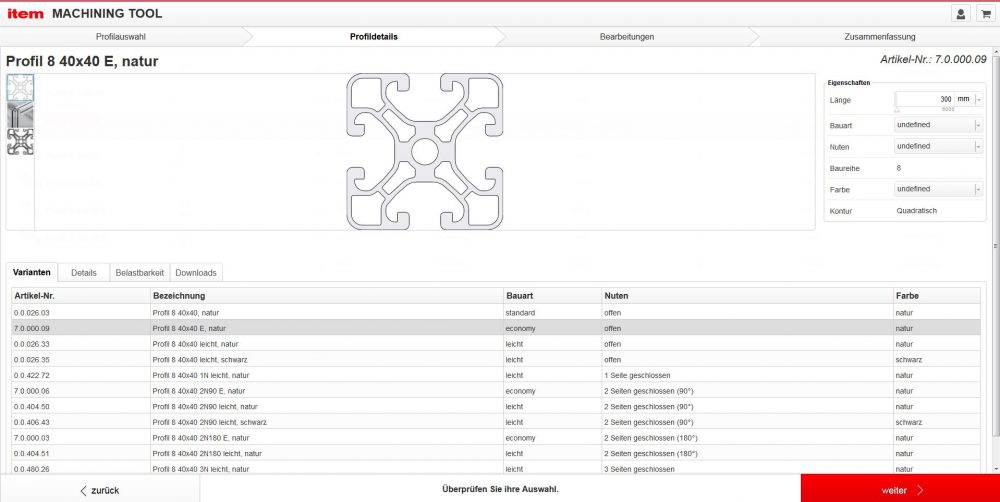

To further complicate matters, the above description doesn’t even touch on the crucial matter of picking the best possible profile for the engineering task at hand. Entering the relevant customer features in the item Machining Tool immediately narrows down the overview of all possible profiles to a selection of suitable candidates. The Tool even takes care of calculations and shows which profiles satisfy the requirements for profile deflection – as per the relevant length and force specifications. The precise values of the calculation are also shown. With this as a basis, users can easily work out which of the selected profiles are best suited to their construction.

If there are several matches, additional filters can be used to refine the result. This means, for example, that all products other than certain lines or very specific profiles can be taken out. This delivers an optimum mix of cost-effectiveness and efficient use of materials. Indeed, filter customisation options combined with integrated calculators are a very effective means of avoiding over and undersizing. In technical terms, the Machining Tool is based on cutting-edge Web technology, which means it doesn’t need to be installed, doesn’t rely on a plug-in or app and can be used on any PC, smartphone or tablet.

Includes profile machining and project documentation

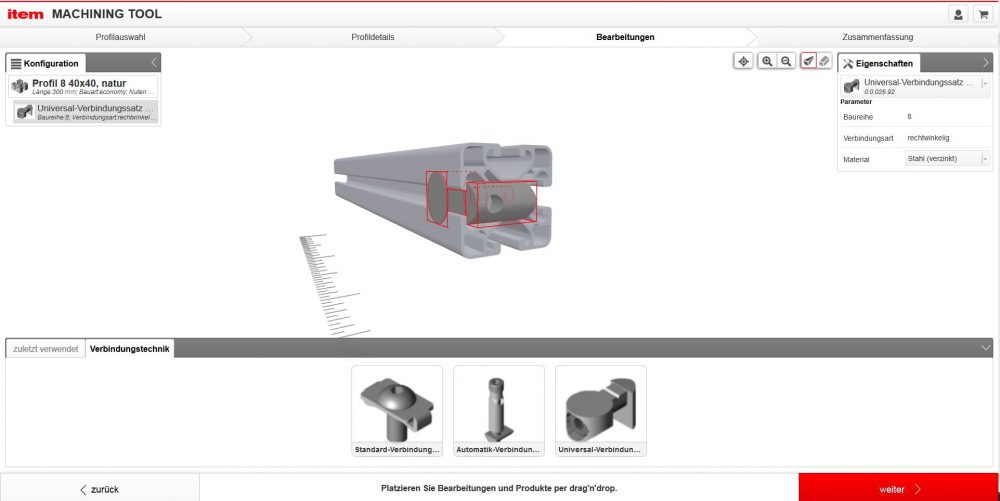

Another advantage of the state-of-the-art technology behind the tool is that the profile is shown in a 3D view that can be freely rotated and scaled. Also included is a selection of fasteners that can be added directly to the 3D drawing via drag & drop functionality. The integrated logic ensures fasteners can only be positioned at locations where it is technically possible to install them. During this same step, all the connection processing types such as through holes, stepped bores and threaded bores are automatically and accurately positioned as appropriate to the relevant fastener. Creating a 3D model like this in a CAD system can easily take several minutes, but the same process using the item Machining Tool can be completed in a matter of seconds.

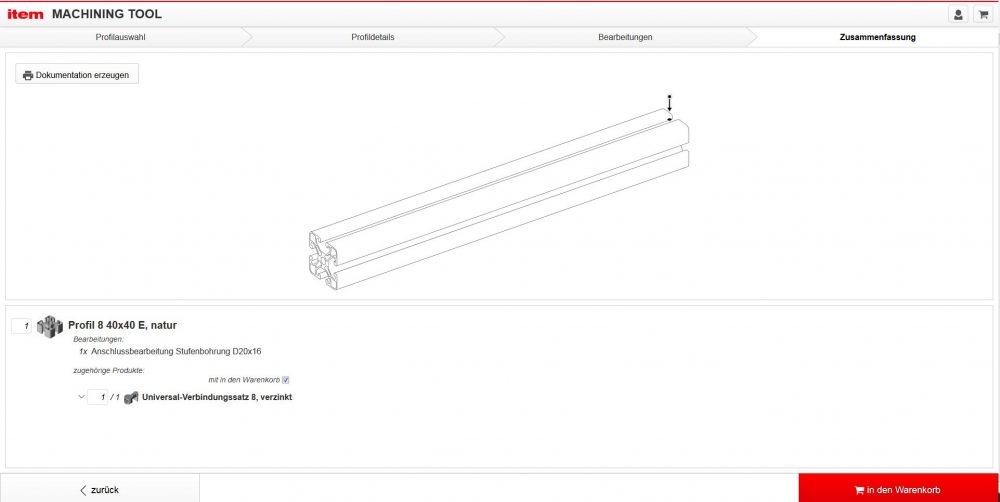

Integrated project documentation is also part and parcel of this efficient end-to-end concept. Once the configuration process is finished, complete project documentation is automatically compiled to document all positions and dimensions in a technical drawing. This drawing is then automatically generated by the system with just a single click so that all information is available for high-precision production operations.

Place orders directly from the item Machining Tool

To round things off nicely, the Machining Tool is also integrated into the item Online Shop, which saves even more time. After logging in, business customers can see the value of the machined profile straight away and order it online – along with fasteners and accessories, if they wish. Project data is transmitted in seconds and the precision-machined profiles can be dispatched within 72 hours.

Simple and efficient in every step

The item Machining Tool makes the most of all the advantages offered by digitalisation in every single step of the profile ordering process – from the idea to the machined profile of choice. As a user-friendly online tool, it ensures efficiency in day-to-day engineering work, cuts costs and saves time, too.

Do you want to keep up to date on how digitalisation is simplifying your engineering work? Then we have something that might just help: simply subscribe to the item blog by completing the box at the top right!