How combining a digital and an analogue solution helps staff learn new packing tasks much more quickly.

Co-packing is used in numerous sectors. It refers to a company outsourcing the packing of a proportion of its products to a service provider due to lack of capacity or space. Remscheid-based Sopp Industrie GmbH provides co-packing for a well-known chocolate maker. Specialising in the production of ribbons, bows and packaging, this tradition-steeped company was originally founded in 1888. It is one of the world’s largest manufacturers of handmade decorative bows. This makes it ideally placed to pack branded chocolates in stylish packaging, in the form of a sledge or birdhouse, for example. That’s why Sopp takes care of the Europe-wide co-packing for all the chocolate maker’s products other than raw chocolate. However, time and again, certain chocolate products may need to be packed in smaller quantities. To ensure staff can learn new packing processes quickly, Sopp uses a combination of the “Smart Klaus” cognitive assistance system from Optimum data management solutions GmbH and an ergonomic work bench from item.

New ergonomics study

This study shows what ergonomic measures are already being used in manual production. Find out more and see how you compare – how far ahead is your company?

GET YOUR COPY NOW!

Advanced technology for quality control and training

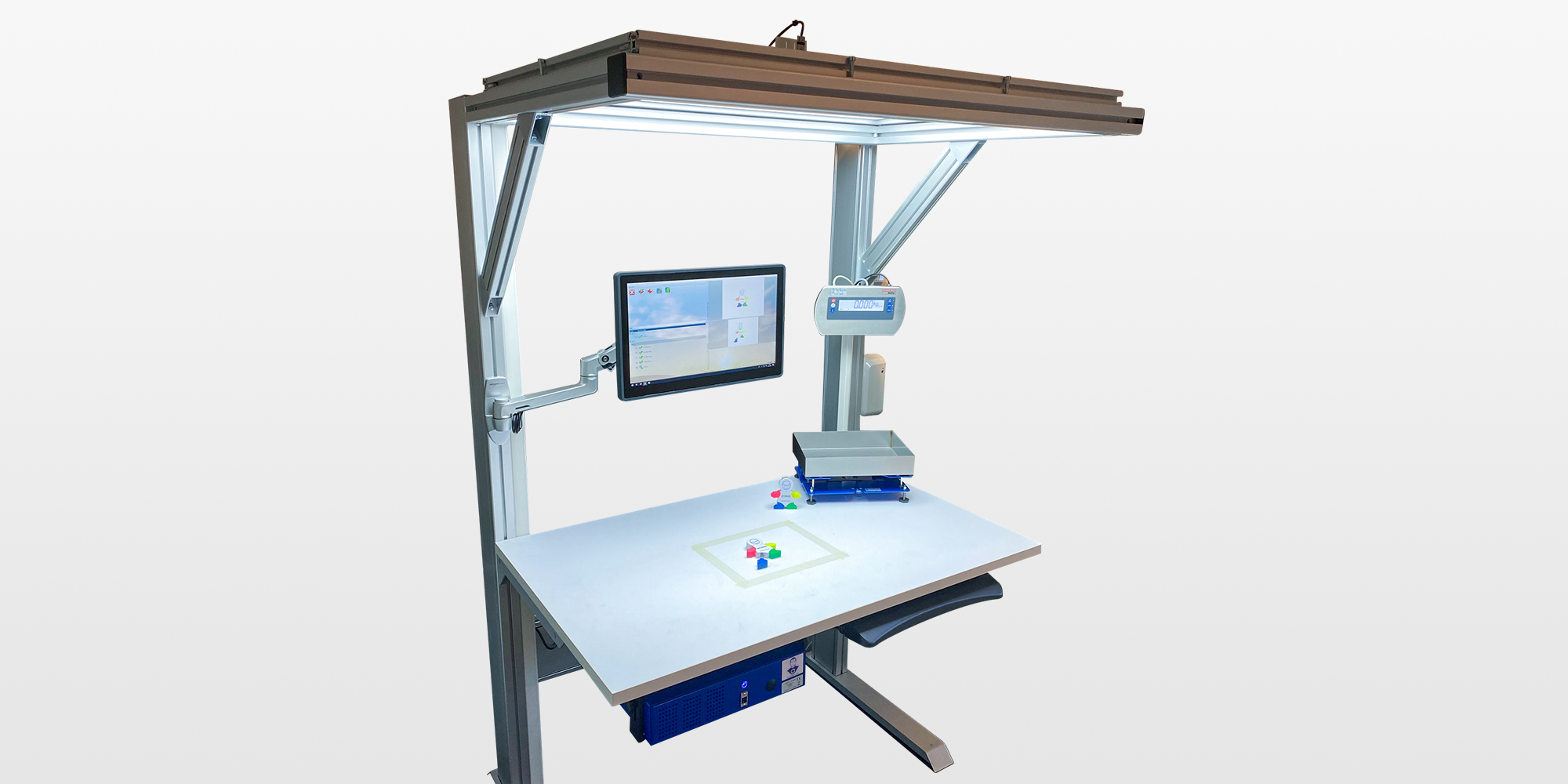

A cognitive assistance system is a technical system that uses new data input and existing data to show solutions and thus support human users. The best-known example of such a system is probably the everyday satellite navigation systems found in most cars. A system such as “Smart Klaus” for industry goes well beyond this: “A light panel is located right at the top of the work bench, on the Table Overhang, while a camera system is installed in the centre. The camera watches the work bench from above, and the software uses image recognition to check whether the various processes are being carried out correctly,” explains Magnus Blombach, project manager and sales engineer at Sopp. For this purpose, each of the relevant processes needs to be defined. At the same time, the worksteps stored in the system serve as a digital guide, leading the employee through the work process step by step at a monitor. A wide range of media can be used to provide greater clarity, from text and images to self-made videos with commentaries. The intelligent system uses the parameters entered (for instance, contours, colours or fonts) to check whether the desired result has been achieved. If everything has gone well, the next stage in the packing process is started immediately but, if it hasn’t, the employee is prompted to make corrections. A set of scales on the right-hand side of the bench can be used for additional checks, as correctly packed goods will have a specific, predetermined weight.

Thanks to the cognitive assistance system’s digital guide, tasks can be performed at short notice even without prior training. If actual training is scheduled, though, no training personnel are needed for this, thanks to the user-friendly audiovisual presentation.

Originally, “Smart Klaus” was to be deployed for quality control purposes on a flow line at Sopp, where it was to count individual products in packs – for advent calendars, for instance. “However, after several discussions with Optimum, we discovered that doing that on the fly isn’t all that straightforward yet. All the same, we were very impressed by “Smart Klaus”, so we also wanted to use it differently. The system is actually used in more complex applications – for soldering printed circuit boards or assembling switch boxes, for example – yet it’s exactly what we need, too,” says Blombach. This brings us to the current area of application – if smaller quantities of a product need to be packed, because additional display stands in shops need to be filled, for instance, this takes place at a standalone work bench. The entire packing process is depicted at this work bench, unlike on the production line, where only one workstep is performed at each station. Thanks to the cognitive assistance system’s digital guide, such tasks can be performed at short notice even without prior training. If, however, actual training is scheduled, training personnel are no longer needed for this, thanks to the user-friendly audiovisual presentation.

Ideal partner for a cognitive assistance system

When it came to configuring the perfect work bench for the cognitive assistance system, it didn’t take long to choose item. For Steffen Schubert, who has been working as a fitter at Sopp for thirty years and is responsible for small specialist machinery, flexibility is the key advantage of the item Work Bench System: “Whether fasteners, angle brackets or covers, there’s everything you need. It’s very user-friendly and saves a lot of time. That benefits us enormously.” The work bench was supplied custom-configured and preassembled. The company then only needed to set up “Smart Klaus” on site, including straightforward steps such as attaching the light panel and mounting an image processing computer. A special slewable Monitor Arm ensures users can adjust the media playback to suit their specific needs. Thanks to its modular design and flexibility, the bench is easy to adapt and extend, making it perfect for combining with a digital solution such as a cognitive assistance system. “We’re interested in continuing to work with item. The Online Shop is particularly well-designed, as are the various tools. You can create designs on screen yourself – that’s something I like very much,” Schubert points out.

Are you interested in ergonomics and what the working world of the future will look like? Then we have something that’s right up your street! Simply subscribe to the item blog by completing the box at the top right.