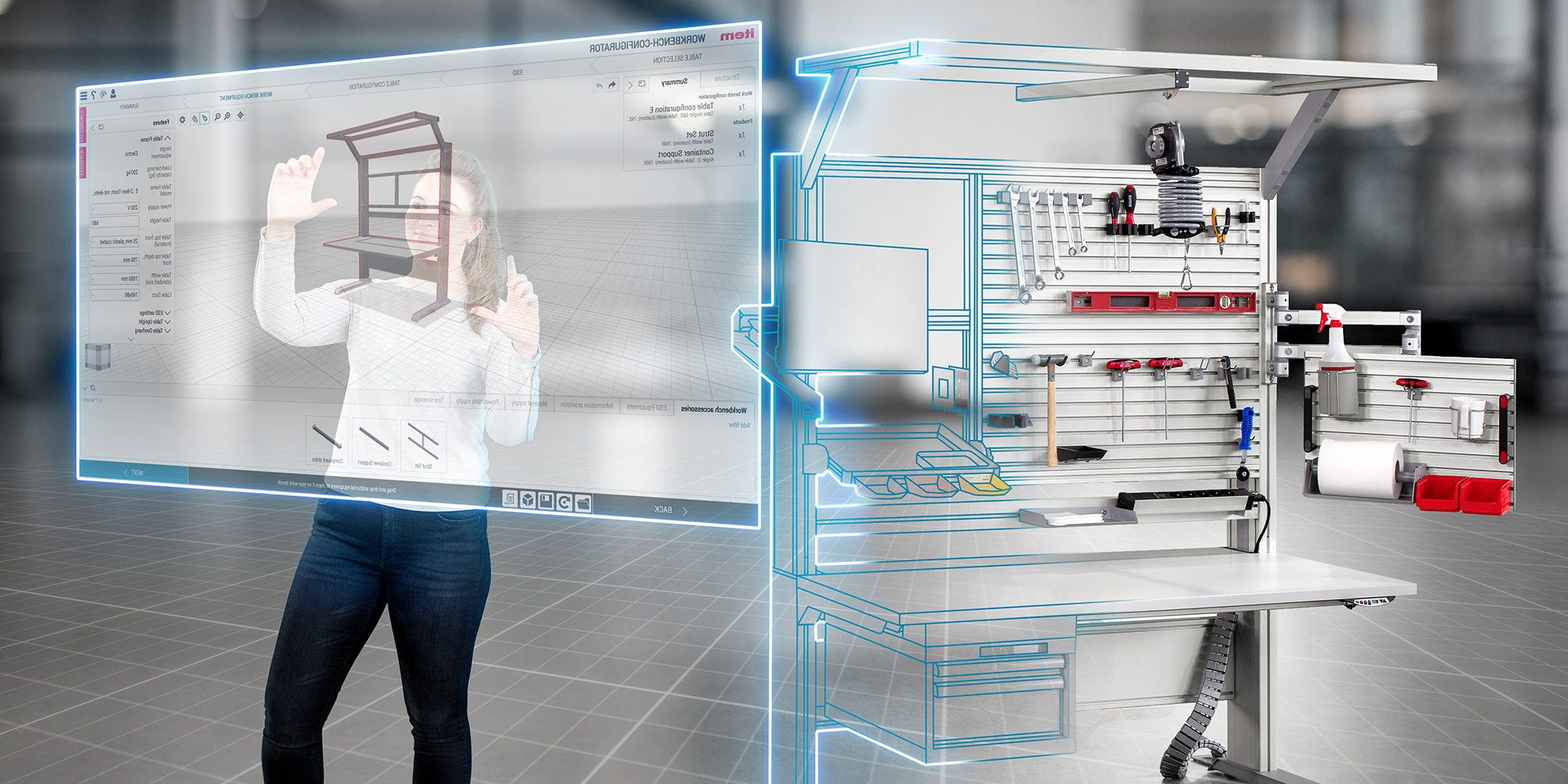

Thanks to the new online tool from item, designing an assembly work bench has never been so quick and easy.

Numerous interlinked aspects are involved in designing an assembly work bench. Ergonomic principles should be taken on board and implemented to effectively prevent musculoskeletal conditions. Although height-adjustable work benches and chairs play a key role in this context, they simply provide a basis to which further solutions meeting your own particular requirements need to be added. Factors to be considered when setting up an assembly work bench in a production environment, for example, include the optimum handling area for the individual operator and ergonomic material supply. If electronic components are being handled, ESD safety also needs to be systematically taken into account when designing assembly work benches. That normally means a great deal of effort is involved in planning a work bench of this kind, but the new Work Bench Configurator from item makes this process much quicker and easier. Planning their assembly work bench directly in the browser in 3D, users benefit from intuitive drag-and-drop controls and numerous intelligent functions that also save time.

Configure industrial work benches online

Discover what the new Work Bench Configurator with its 3D view and smart functions can do – especially for ESD safety. Put together your very own manual production work bench without leaving your browser.

FIND OUT MORE

Design an assembly bench in 3D with just a few clicks

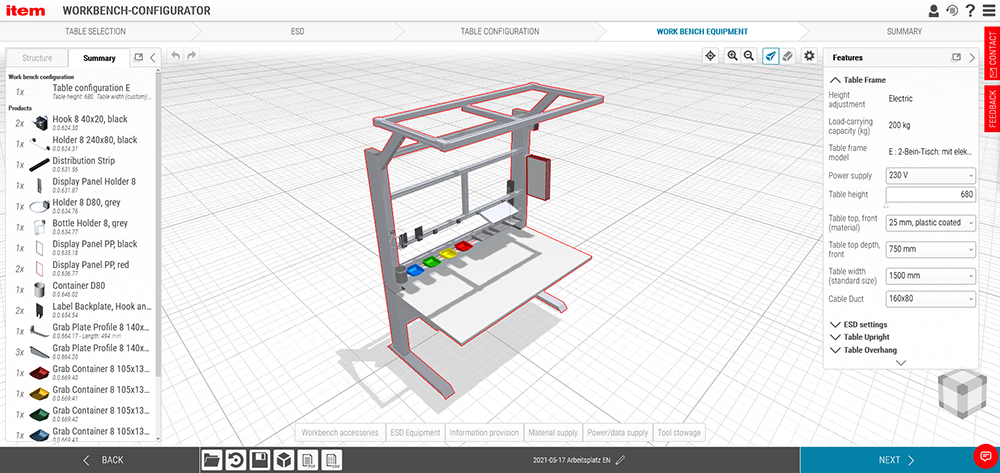

Just like the item Engineeringtool, no additional software is required to use the Work Bench Configurator. All you need to make a start on designing your work bench for manual assembly is an end device with internet access and a standard browser. As with its counterpart for digital engineering, you can zoom in and out and move around freely in the Work Bench Configurator’s working area with its 3D view. This provides an accurate, detailed preview of the assembly work bench.

Smart functions and built-in rules guide you towards a workable solution when designing your assembly work bench.

When configuring the bench in the 3D engineering area, components are simply dragged and dropped into place. The possible positions in which they can be fitted are also displayed. Intuitive operation makes equally light work of customised adjustments – positioning a Strut Set and locating accessories, for instance. Smart functions and built-in rules guide you towards a workable solution when designing your assembly work bench. For example, necessary fastening elements are added automatically. You also have all the flexibility you need to customise the assembly work bench to your exact requirements.

Valuable benefits for assembly work bench design

Various preconfigured models are available to make getting to grips with the Work Bench Configurator even easier. These range from an ergonomic, electrically height-adjustable standard bench all the way through to a work bench with comprehensive ESD protection. The deliberate focus on user-friendly operation isn’t restricted to the actual work bench design for manual assembly. Info points provide additional information and offer valuable support with technical matters. The comprehensive documentation includes all the details required for the particular project and its configuration. What’s more, every document has its own clickable QR code and a URL. These are easy to share with colleagues, who can then immediately view the assembly work bench design online in the Work Bench Configurator. Last but not least, the free online tool for designing assembly work benches requires no prior installation or special hardware.

Another key advantage of the Work Bench Configurator is that it makes no difference to the delivery time whether the user selects a standard work bench size or opts for customised dimensions.

Easy access to the configuration makes communication and teamwork far easier. Naturally, CAD data can also be exported – for use in further planning systems, for instance. Another key advantage of the Work Bench Configurator is that it makes no difference to the delivery time whether the user selects a standard work bench size or opts for customised dimensions. Digitalisation makes the special solution standard, which saves both time and money. There’s also a dedicated assembly service. Accessories can be delivered already fitted to make commissioning even quicker and easier.

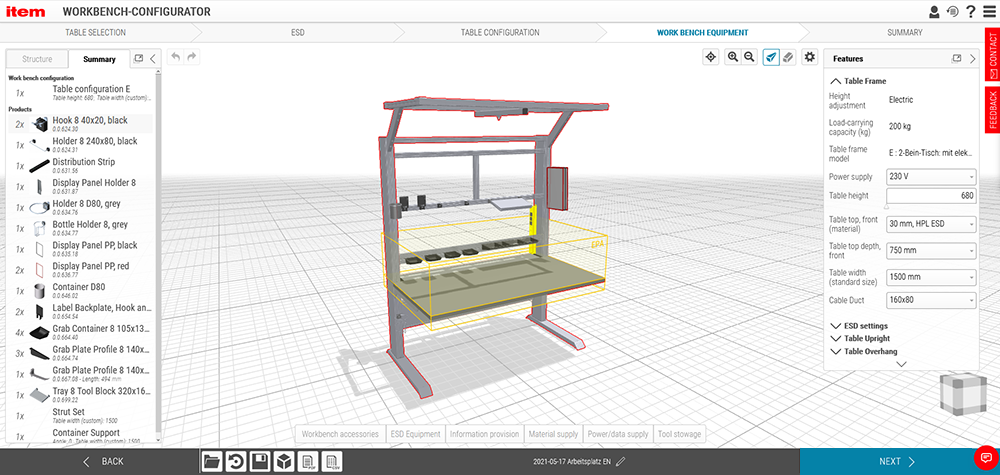

EPA visualisation and more – designing an ESD assembly work bench online

ESD safety has top priority when it comes to work bench design, something that is evident right from the start of the configuration process. Users are asked whether ESD protection is required for their planned work bench. A decision is needed here to ensure this vital safety aspect is taken into consideration when designing the assembly work bench. If ESD protection isn’t required, the rest of the associated steps can be dispensed with. What’s more, users can change their mind at any time down the line. A click of the mouse is all it takes to activate the ESD safety functions. For example, the bench’s working surface is then changed to an ESD-safe version.

When it comes to ESD safety, the definition and visualisation of the electrostatic protected area (EPA) is a particular highlight of the Work Bench Configurator.

The key highlight of the Work Bench Configurator in this connection is the possibility of defining the electrostatic protected area (EPA). This is then visualised and a yellow warning appears if a part that isn’t ESD-safe is placed inside the EPA. Users also benefit from complete flexibility, because they can define very precisely where ESD protection is required and where it isn’t when designing their work bench for manual assembly. Although warnings are always displayed when non-dissipative components are placed inside the EPA, it’s ultimately up to users to decide whether to reposition, tolerate or remove the potential risk. They can also opt for item not to fit these components, in which case they are delivered separate from the work bench and can be retrofitted if necessary. In any case, non-dissipative products are also identified in the ESD documentation. Furthermore, customers receive a special ESD measurement log and can therefore rest assured that the bench has an ESD-safe design on delivery.

Do you want to stay up to date with assembly work bench developments? Then we have something that’s right up your street! Simply subscribe to the item blog by completing the box at the top right.