How the item Academy is taking knowledge transfer to a whole new level when it comes to lean principles.

Lean production is an extremely effective way of making production processes more efficient and reducing throughput times. This is demonstrated both by our own experience and by success stories such as that of U.S. company Wiremold, which was made famous by Bob Emiliani’s book entitled “Better Thinking, Better Results”. In the space of ten years, Wiremold’s sales shot up from 100 million to 450 million U.S. dollars. However, up to 80 percent of attempts to introduce lean production fail. How can that be? There are two main reasons, and they are closely linked. Lean production is often misunderstood and a number of misleading definitions exist, especially online. Describing lean production as a means of saving on manpower is just one example. Such definitions are simply not true and cause unfounded fears amongst staff.

Key knowledge relating to the lean concept is rarely shared with employees, which can result in them reading up on the subject themselves and potentially coming across inaccurate sources of information. For a long time, in-person events were the only solution to these challenges when introducing lean production. The item Academy now offers a faster and more efficient way for companies to introduce a new concept such as lean production. Its online modules are available in seven languages and can be used free of charge on any end device with internet access.

Online training at the click of a mouse

Training can be fun! Expand your expertise with the interactive item Academy – from the very basics to in-depth product know-how.

EXPAND YOUR TRAINING NOW

A flexible and well-founded introduction to lean production from the item Academy

In-person events providing an introduction to lean production are without doubt useful, but it’s vital to ensure that as many staff as possible quickly attain a specific level of knowledge. One-off events of this kind often have limited success – they need to cover every aspect and the management team understandably wants to see rapid results, but certain obstacles arise when the aim is to introduce a large number of employees to the world of lean production in a limited period. When it comes to the necessary lean experts, capacities are also limited. If there are already lean specialists at a company, they’re usually one in a hundred. What’s more, especially when introducing lean production throughout international companies, the multilingual nature of the task is often beyond individual experts.

The only requirement to use the item Academy is a free item user account and any end device with internet access, which means any employee can learn more about lean production on a flexible basis.

Space-related considerations are also playing a greater role than ever before due to coronavirus. Which rooms are available, and how many people are allowed in each one? Coordinating extensive in-person training courses is challenging as well. After all, they tie up all participating staff, which leads to a lack of resources elsewhere. The item Academy online training modules on the lean philosophy provide an excellent complement or alternative to such courses. The only requirement to use the item Academy is a free item user account and any end device with internet access, which means any employee can learn more about lean production on a flexible basis. All content is based on well-founded knowledge and years of experience. In contrast to an in-person event, there are no time or space restrictions. An unlimited number of staff can complete the interactive introduction to lean production whenever and wherever they want. The content is available in a total of seven languages – English, German, French, Italian, Spanish, Polish and Mandarin.

A well-thought-out online introduction to lean production

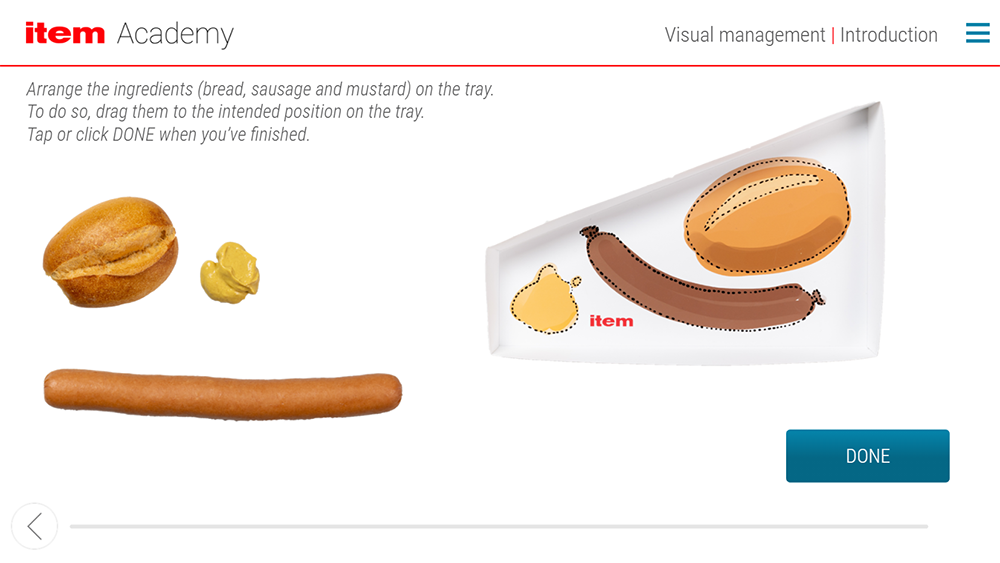

The online training on the lean philosophy in the item Academy has been specially designed in a way that ensures lean production can be understood as a system. This is important, because lean production methods are often presented in isolation, which can create the impression that there is a kind of “toolbox” consisting of various methods. However, learners are then left unsure about which method should be used where. The item Academy provides a systematic introduction, with lean production methods presented in an overarching context. The introduction starts with the origins of lean production in Japan and the successes the Toyota Production System achieved there. This is followed by further modules with a common theme. In this way, participants learn about the goals of lean production, and about the methods, principles and “tools” that help them with their work. If you already have an item user account, you can access the individual modules directly using the following links:

- Basics of lean production: How to optimise processes and factory equipment using lean production principles.

- Value-stream mapping: Learn to depict the value stream and identify the current situation of your business processes.

- Value-stream design: Model flows of materials and information, and design future value streams.

- Push and pull: Introducing the pull strategy eliminates superfluous and expensive warehousing and also unnecessary transport outlay.

- One-piece flow: Discover the one-piece-flow concept – the lean alternative to traditional batch production.

The online training providing an introduction to lean production also includes two standalone modules that are more conventional – Visual management and Assembly line design.

Information about the Lean Production Building Kit System and certification

Another section of the item Academy online training also addresses the lean concept. If you have already made some headway with the introduction of lean production and are exploring the options for lean factory equipment engineering, you will find lots more helpful information in the Lean Production Building Kit System online training modules. The components of the Lean Production Building Kit System have been developed specifically for the special requirements associated with lean production, so they feature a modular, lightweight design and long-lasting versatility. The modules cover topics ranging from stability when designing rack systems and the basic elements of the Lean Production Building Kit System for designers to the simulation of step-by-step design in the item Engineeringtool and the basics of Karakuri/LCA.

Users can obtain certificates confirming their specialist knowledge of the lean philosophy and the Lean Production Building Kit System. When they pass the exam, their certificates are sent out by post, with item covering all certification costs.

Users can also obtain certificates confirming the specialist knowledge they have acquired relating to the Lean Production Building Kit System – item certified engineer Lean Production Building Kit System Level 1 and item certified technician Lean Production Building Kit System Level 1. Companies can provide additional motivation to obtain certification by offering gifts or vouchers. The basic aim in all cases, though, is to use lean production and item solutions to make life easier for staff and enable them to actively contribute to their company’s growth. The first step is to impart this know-how, but it then provides outstanding motivation for day-to-day work.

The lean philosophy’s universality means it can also be applied to other item building kit systems, including the Work Bench System. Obtaining item certified engineer Work Bench System Level 1 certification is another attractive option for staff with an interest in the lean philosophy. This includes all modules providing an introduction to lean production. item certified engineer (ICE) certifications are generally ideal for all users who want to use our products to plan solutions or have these solutions assembled, while item certified technician (ICT) qualifications are designed for users who actually carry out the assembly work themselves. Prior to the concluding online test, users need to complete a curriculum covering various product and topic areas. When they pass, their certificate is sent out by post, with item again covering all certification costs.

Are you interested in fascinating reports and innovations from the world of lean production? Then we have just what you’re looking for! Simply subscribe to the item blog by completing the box at the top right.