The current skills shortage is making robots more relevant than ever.

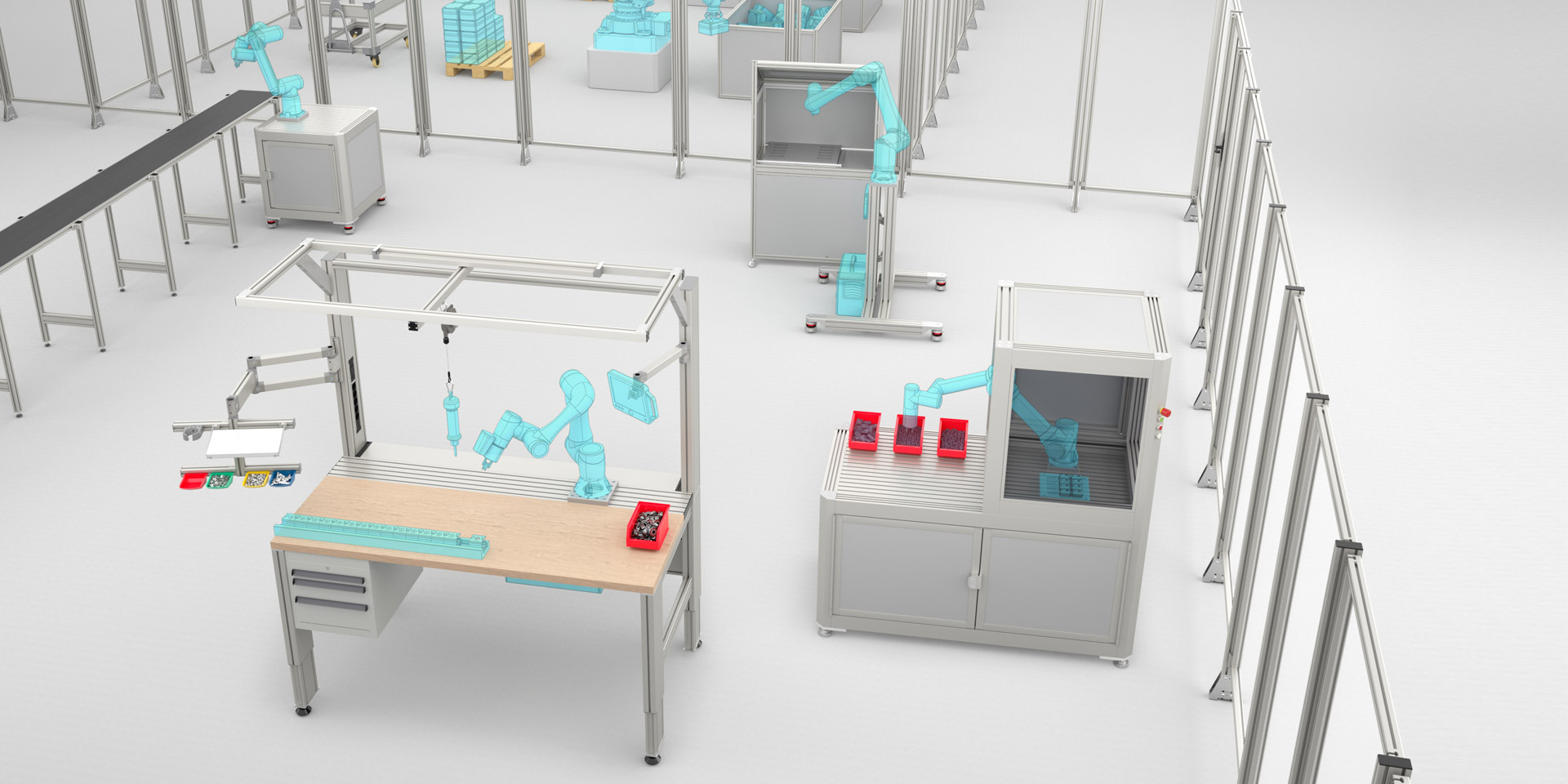

For a long time, it was particularly difficult for SMEs to take their first steps with robotics applications. The emergence and success of collaborative robots (cobots) has made all the difference. Their straightforward programming, short set-up times and easy integration make them incredibly flexible. For example, they are already proving very handy in areas such as screw fixing and welding, assembly and sorting and palletising and machine loading. Sales of conventional industrial robots are also on the up. Some 486,800 units were sold worldwide in 2021 – an increase of 27 percent. Regardless of which type of robot is being used, an appropriate integration solution is required – from robot tables and cabins/enclosures to guards. The item Building Kit System for robot solutions offers a key advantage in such applications. Its end-to-end modularity means components from all product categories, including mechanical engineering, conveying technology, linear technology and lean production, can be flexibly combined.

Discover exemplary robot solutions

Find out about all the details and additional robot solutions in the interactive ePaper – including videos and further links.

Inform now

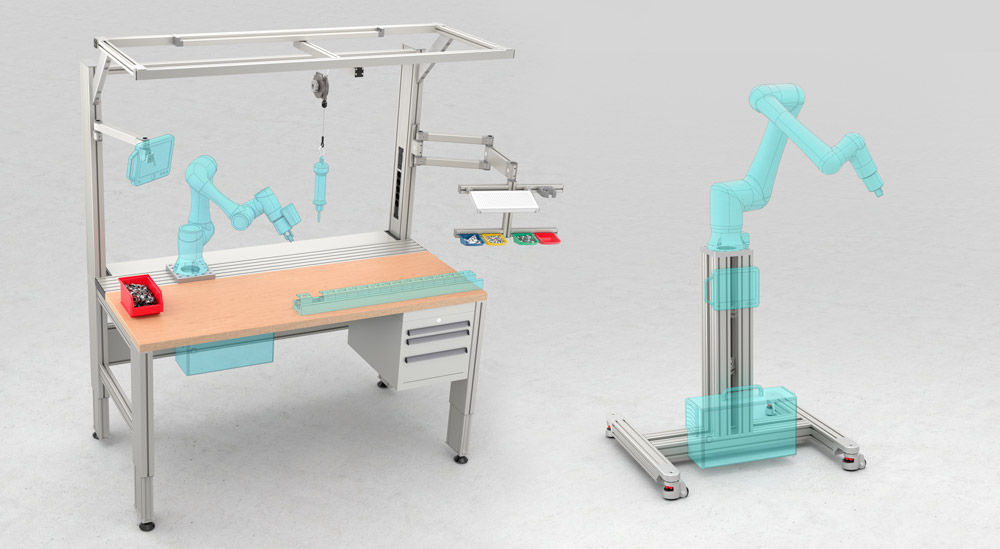

Collaborative work bench and mobile robot column based on item technology

The collaborative production work bench gives assembly workers the best possible support. It has a heavy-duty Profile 8 (160×40 or 200×40) at the rear for attaching a cobot. The robot arm and other accessories can be positioned anywhere along the grooves. One particularly practical feature is that existing item work benches can be easily converted to this solution. All you need to do is move the pre-existing table top forwards. Thanks to four electrically height-adjustable Lifting Columns, the work bench can be adjusted to an ergonomic working height at the touch of a button. What’s more, there is plenty of space below the table top to fit the cobot control system.

The modularity of the Building Kit System for robot solutions makes it easy to modify the column, base frame and equipment.

Pivot Arms, accessories and LED Light Fittings can be added to the work bench at any time to adapt it to the relevant production process. The robot column for mobile cobot use is recommended when switching between different areas of application. Thanks to its stable frame, you can quickly move even large cobots to where they are needed. The frame has a mounting surface measuring 200 x 200 mm for attaching a cobot using Robot Mounting Plate 8. The mobile cobot’s Jacking Castors make sure it always stays securely in place, while an integrated height adjustment feature levels everything up if the floor is uneven. The modularity of the Building Kit System for robot solutions makes it easy to modify the column, base frame and equipment.

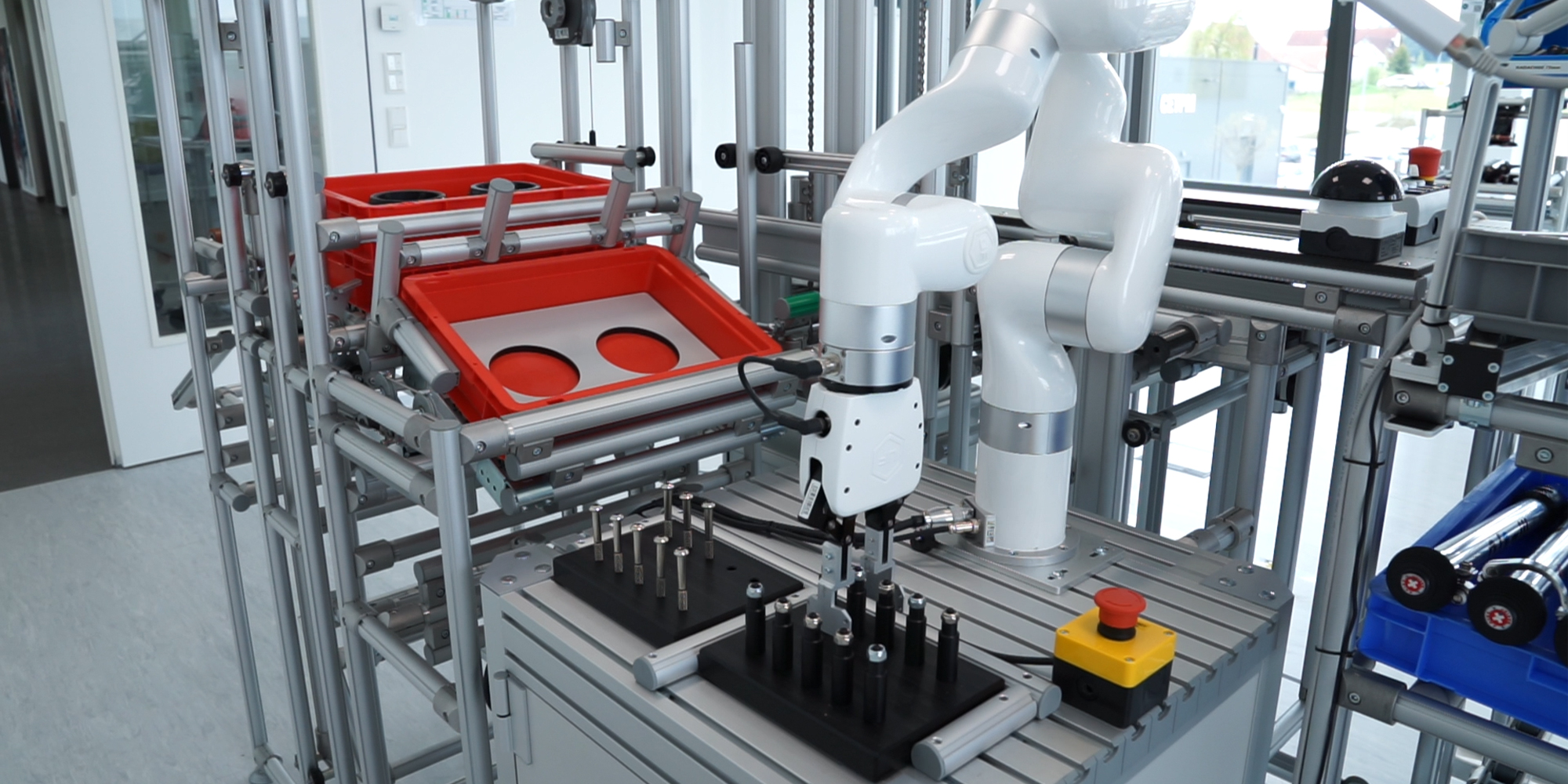

Systematic protection for staff working with all kinds of robot solutions

The partially enclosed cabin for using cobots offers protection exactly where it’s needed. The robot arm can use the entire work area, while removable, adaptive panelling protects staff. The work process can be continuously monitored by looking through the large, impact-proof windows. Line XMS corner profiles with integrated cable conduits are used in the frame, thereby reliably protecting all cables. Special Fastening Sets function as cable feed-throughs between vertical and horizontal profiles, which makes it easy to separate the different sections. The frame also incorporates operating elements such as the Emergency Stop Button.

Enclosures and guards can be set up as free-standing structures around a robot or attached to a machine base.

The base section offers plenty of space for the control system, working materials and other peripherals. All in all, Line XMS helps create a clear design and a high-quality working environment. item enclosures and guards really come into their own when dealing with larger dimensions and higher risks (associated with industrial robots, for example). They create safe and secure workplaces with controlled access. Appropriate guards as referred to in the Machinery Directive can be set up as free-standing structures around a robot or attached to a machine base. The system’s modularity means everything fits together perfectly – the enclosure, the robot workstation and even the associated intralogistics.

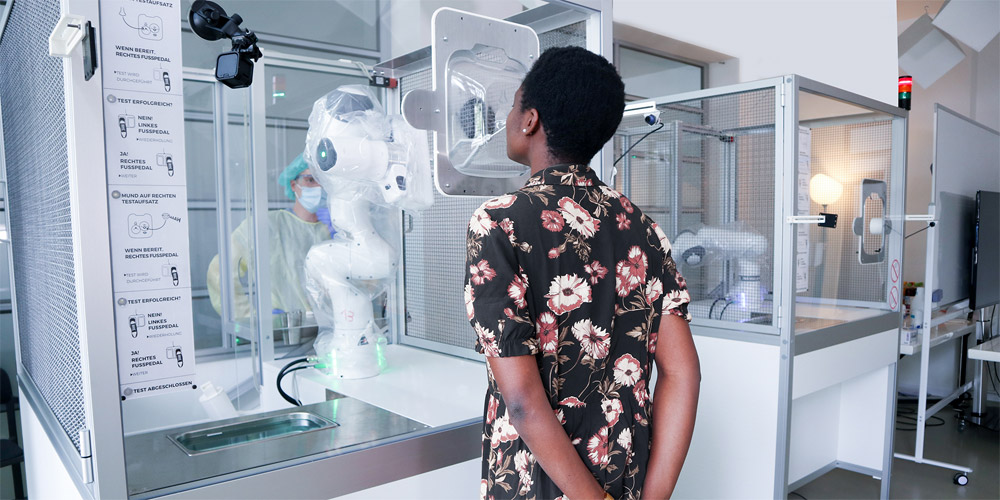

Innovative automation of coronavirus tests

FRANKA EMIKA GmbH is a true innovator in the field of human-robot collaboration. The Munich-based company is using Line X from the MB Building Kit System for the frame of an automated coronavirus test station. At its heart is the SR-NOCS (= Swab Robot for Naso- and Oropharyngeal COVID-19 Screening). Using this swab robot reduces the risk of staff getting infected and also boosts test capacities. The SR-NOCS is located in a sealed enclosure, from where it autonomously takes nose and throat swabs. Two plexiglass panels separate it from the person being tested. The inlet port in the front panel is changed after every test. The robot slides a plastic attachment through the port before sliding a swab – supplied by a member of staff – through this attachment for the test.

Profile X is used in the station because of its smaller outer radius.

The nose and throat swab is initiated using a foot pedal, which means the person being tested retains full control at all times. Line X proved to be an ideal solution for a hygiene-sensitive application such as a coronavirus test station. Besides its smooth, unbroken surfaces, there’s a further advantage for FRANKA EMIKA staff, who are familiar with item products. “It was very important for everything to be as flush as possible to make disinfection more effective. Profile X is used in the station because of its smaller outer radius,” explains Industrial Designer Benjamin Loinger from FRANKA EMIKA, who is an expert on robot solutions. Profiles XMS, which are based on Line X, were also designed for a safe working environment.

Ergonomic robot table with quick-change system

As a member of the item pluspartner network, GRIP GmbH Handhabungstechnik also knows all about the Building Kit System for robot solutions. “We use item profile technology for all testing and assembly equipment. The Building Kit System is very versatile, so we also use it for specialised fixtures, enclosures, racks, guard-rails and work benches,” says GRIP Managing Director Hasan Canti. GRIP’s newly developed robot table based on Line XMS combines a classy design with excellent functionality and ergonomic handling. The robot technology and peripherals are perfectly integrated into the table. For example, the way the control cabinet has been fitted means it can’t be seen from the outside, but is instead located in a drawer.

The cobot can be fixed onto the Groove Plate quickly – thanks to various item Mounting Plates for cobot integration and the GRIP Base Connector.

To access the control cabinet during operation, the drawer is pulled out, and the lid is opened from above. This makes working on terminals inside the control cabinet much more ergonomic. The cobot can be fixed onto the Groove Plate quickly – thanks to various item Mounting Plates for cobot integration and the GRIP Base Connector. The quick-change system of this UR+ product partner makes the task of connecting the robot arm and table very straightforward. A device made from aluminium profiles that is capable of accommodating several GRIP grippers can also be attached. Thanks to the GRIP Auto Connectors, the cobot then quickly switches between various grippers for different applications. The robot table can be extended at any time – with additional drawers, enclosures or safety technology, for instance.

Want all the latest updates on innovative robotics applications? Simply subscribe to the item blog by completing the box at the top right.