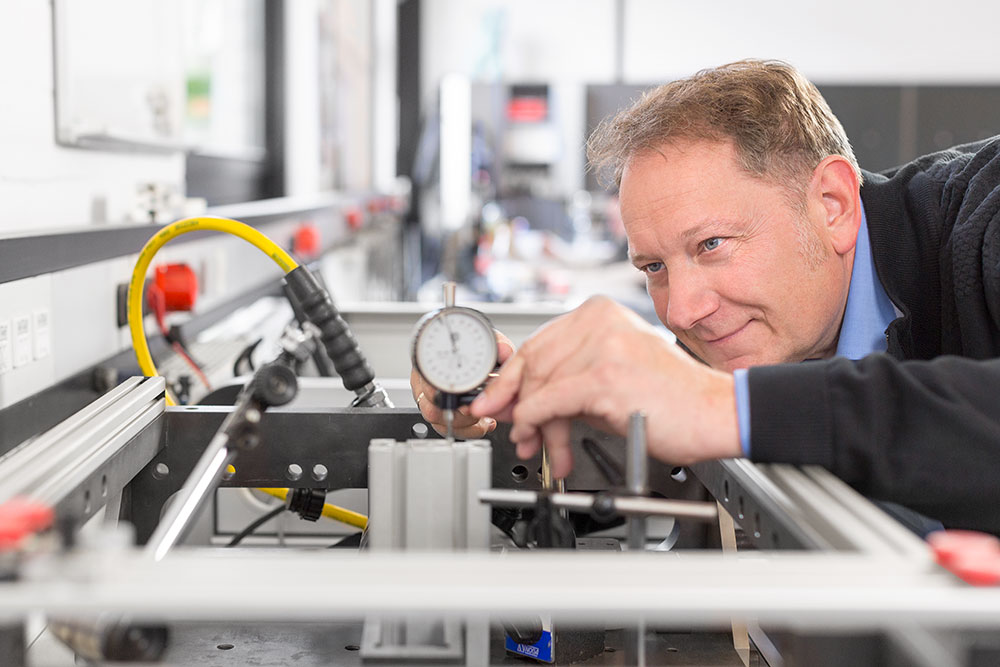

Expert advice – an interview with plenty of practical tips for users of the MB Building Kit System.

Anyone who is familiar with item fastening technology will appreciate the quality of the profiles and fasteners. In this interview, item engineer Markus Allwicher explains what’s behind the quality of item fastening technology and what you need to bear in mind when planning a design.

One principle, unlimited possibilities – that’s the item philosophy. How exactly does that play out when it comes to mechanical and factory equipment engineering?

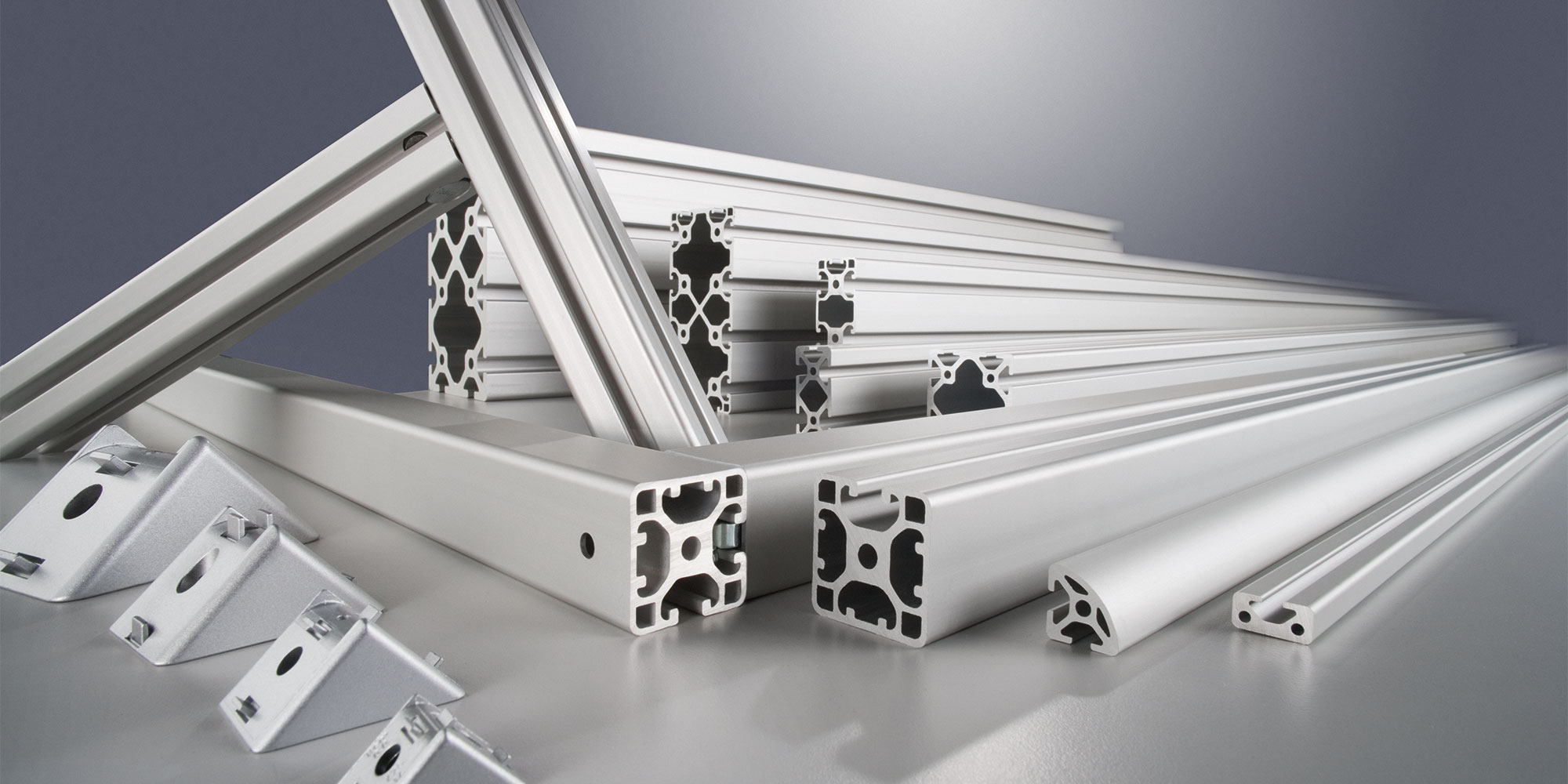

Our MB Building Kit System is designed for maximum versatility and stability. The core products we provide – profiles and fasteners – enable companies to build many different constructions, which they can subsequently modify and convert. For example, if you work in the specialist mechanical engineering sector and have integrated a machine into a welded frame structure, making any kind of modification is a very complicated task. It helps if the frame has a modular design and can be altered. This modularity is particularly important when selecting a profile. Line 8 is the most versatile option.

What do I need to bear in mind if I want to make the most of this versatility over the long term?

Basically speaking, Line 8 is suitable for most constructions. It’s our all-rounder. In other words, if you’re starting the planning process and want to keep things as flexible as possible, you should definitely consider Line 8. In many cases, the same construction can be built using different lines. The decisive factors when selecting which line and which fasteners to use are stability, functionality – which depends on the number of different accessories – and cost optimisation. Needless to say, many articles from different lines can also easily be combined. In the case of series production, this results in solutions that satisfy the requirements relating to the construction on a cost-optimised basis. In the case of other construction types, the results are solutions that promise maximum stability while keeping the weight as low as possible – using the line’s lightweight or economy version, for instance. Both these versions use less aluminium and therefore weigh less. From a manufacturing perspective, they are very slender.

Laboratory trolleys, subframes and testing booths

Which line is the right one for your particular application? The “Introduction to profile technology” study unit tells you all you need to know about the various item lines and variants. It also provides you with details of the stresses each line can accommodate.

GO TO THE ITEM ACADEMY

How do the lightweight options affect load-carrying capacity?

Weight-optimised profiles have a very sophisticated geometry and are more complicated to manufacture than products made from solid materials. It takes years of experience and cutting-edge, scientific design engineering methods to achieve the ideal balance between stability and the amount of aluminium used. The weight-optimised lightweight and eco versions have a lower load-carrying capacity than the line’s basic model.

What forces will normally be acting on my constructions?

In all likelihood, the usual forces will apply, that is to say compressive, tensile and shear forces, plus torques in all three spatial dimensions. This creates a mixed load. The only way you can get detailed information about the loads that are acting is by carrying out a computer-based simulation. To obtain a simplified but reliable idea of the load scenario, we look at the design’s connection points, the material loading of the fastening elements and aluminium profile, and the effects on the structure’s functionality. That’s how we reduce the mixed load. We call the tensile force acting on the connection point the groove load-bearing capacity. The resulting shear force, which displaces the connection point along the groove, is called the groove displacement force. When it comes to the resulting material loading in the aluminium profile, we look at bending and torsion. Torsion plays a less important role here, as the elastic properties of aluminium mean that, when subjected to torsion, it normally loses its function before any material damage occurs.

Selecting profiles and carrying out calculations

What loads can act on my profiles and how do I calculate these? The “Selecting profiles and carrying out calculations” study unit shows you how you can obtain a stable result. It also visualises various constructions and load scenarios.

GO TO THE ITEM ACADEMY

How do I know which item profile is suitable for my design?

Whether or not a product is suitable depends on its strength and durability, but above all on its functionality. Easy handling also plays a role – item profiles are screwed rather than welded together. Thanks to this fastening technology, many designs can be built without any machining. Little or no drilling and tapping is required. Given the durability of our profiles and fasteners, and the fact that our customers use them in various constructions during their product life cycle, it’s also important that we always supply them in the same quality. As a customer, you need to be able to rely on obtaining the same quality and fit if you purchase the same product again years later.

How does item ensure that is the case?

We do our utmost to make sure our products benefit from a consistent quality standard. The product quality is reflected in a great many details. A modular system ensures the products in the portfolio can be combined – even across lines and after a long period of time. Delivery reliability, tolerance zones, surface quality and strength categories must be coordinated, regardless of when customers purchase the products from us.

Want to keep up to date with everything that’s going on in the world of item? Simply subscribe to the item blog by completing the box at the top right.