An item pluspartner is showing how even small businesses can achieve smart process automation.

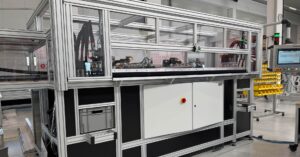

In the paper and packaging industry, short print runs and high demands are common. When it comes to sheet stacking, every manual step costs time and money. That is exactly where the sheet stacker from AXIAL Ingenieure GmbH comes in, precisely and reliably automating the process of palletising sheets of paper and cardboard. The stacker is a compact addition to your existing paper processing equipment and can be connected directly to your cutting plotter. As an official member of the item pluspartner network, AXIAL Ingenieure makes its expertise available, working with other partners in the network to implement innovative projects and resolve complex issues.

AXIAL Ingenieure – solutions from design through to commissioning

Having started out as a design office, AXIAL Ingenieure now develops customised special plant and special machine construction solutions. From design and production through to commissioning, it offers customers a wide range of solutions for a whole host of industries.

Focal points include everything from production chains and complete plant systems to welding, handling and assembly equipment – based on in-house production and subject to high quality standards. Even small businesses with between one and three members of staff can benefit from the AXIAL Ingenieure team’s well-engineered solutions, which always aim to optimise work processes. The sheet stacker project is a direct result of this goal and the close customer relationship, offering a compact solution for the automatic palletising of paper and cardboard that is specifically designed for smaller sheet formats.

The sheet stacker mini BS700x500

“A customer approached us essentially saying they couldn’t find a suitable stacker for their cutting plotter and asking if we could develop one,” recalls Matthias Hoppe, Managing Director of AXIAL Ingenieure. The company initially developed a stacker for large sheet formats up to 3000 x 2000 mm. Cutting plotters and sheet stackers are often marketed as a package. However, many users require a separate sheet stacker that can be connected to specific existing systems. AXIAL soon received a further customer enquiry relating to a solution for smaller sheet formats.

Our sheet stacker for the automatic palletising of paper and cardboard is compatible with any cutting plotter.

The result was the sheet stacker mini BS700x500, which was launched at the end of 2024. Designed for sheets measuring up to 700 x 500 mm, it is ideal for processing small paper formats. The stacker boasts compact dimensions. With a length of 1.70 m, a width of 80 cm and a height of around 85 cm, it even fits into production environments where space is limited. At the beginning of 2025, the company added the sheet stacker midi BS1000x700 – a further variant for the 1000 x 700 mm sheet format – to its portfolio. The stackers are primarily of interest to paper processing businesses that work, for example, with lightweight plastic printing plates and want to use automatic palletising to make their operations more efficient.

How the sheet stacker works – the details of automatic palletising

An automatic stacker for cut sheets of paper and cardboard, the sheet stacker mini BS700x500 complements your existing paper processing machinery. A conveyor transports the cut sheets from the cutting plotter to a sloping delivery section in the sheet stacker. The front edge of the sheet passes over a sensor that starts the delivery process, during which a further conveyor belt takes each sheet, positions it correctly and deposits it on a scissor lift table, where all the sheets are stacked neatly on top of each other.

In the paper and packaging industry, automatic palletising significantly eases the strain on your staff, while also improving process stability and boosting production efficiency.

The scissor lift table is then automatically lowered until the desired stack height is reached. This height is continuously monitored in an automated process. Once the stack is complete, you get a clear signal and can immediately continue with further processing. The sheet stacker benefits from an autonomous control system and is compatible with any cutting plotter. By taking care of palletising for you, it spares your staff repetitive tasks and is a useful addition to your existing paper processing machinery.

Handling all kinds of materials – automatic palletising of different sheets

As anyone who works with paper and cardboard will be aware, no two sheets are the same. They can be thin, smooth and very slippery, but also thicker and more fibrous, and either pliable or very rigid. This was a particular challenge during the development of the stacker. The aim was to ensure automatic palletising would work reliably for as many material properties as possible – regardless of what kind of sheets you want to feed into your paper processing machines.

“A solution based purely on passive sliding would be too unreliable, as sheets behave very differently depending on the gradient and surface,” explains Hoppe. His company therefore deliberately uses a motorised conveyor belt that controls the movement of each sheet. The sheet stacker offers small and medium-sized enterprises (SMEs) an ideal opportunity to add another automated step to their existing machinery.

item Line 8 – a flexible basis

The ingenious combination of materials that AXIAL Ingenieure uses for the sheet stacker mini delivers stability, flexibility and cost-efficiency. item aluminium Profiles 8 40 x 40 provide a frame to which sheet metal production parts and Makrolon panels are added. An integrated control cabinet accommodates the sensor technology and control system, while also acting as a load-bearing element. “Line 8 offers excellent availability, and cut-offs can be supplied quickly,” explains Hoppe. This means solutions such as the sheet stacker can be adapted or extended whenever required.

Line 8 aluminium profiles were selected for the frame. They offer excellent availability, and cut-offs can be supplied quickly. The profiles therefore help ensure projects are completed fast.

Their exceptional versatility makes Line 8 profiles a perfect choice for machines and systems of all sizes. Thanks to their design, these aluminium profiles are a lightweight, robust and flexible solution that lasts for many years. They provide you with a stable, durable basis that is easy to adapt or extend.

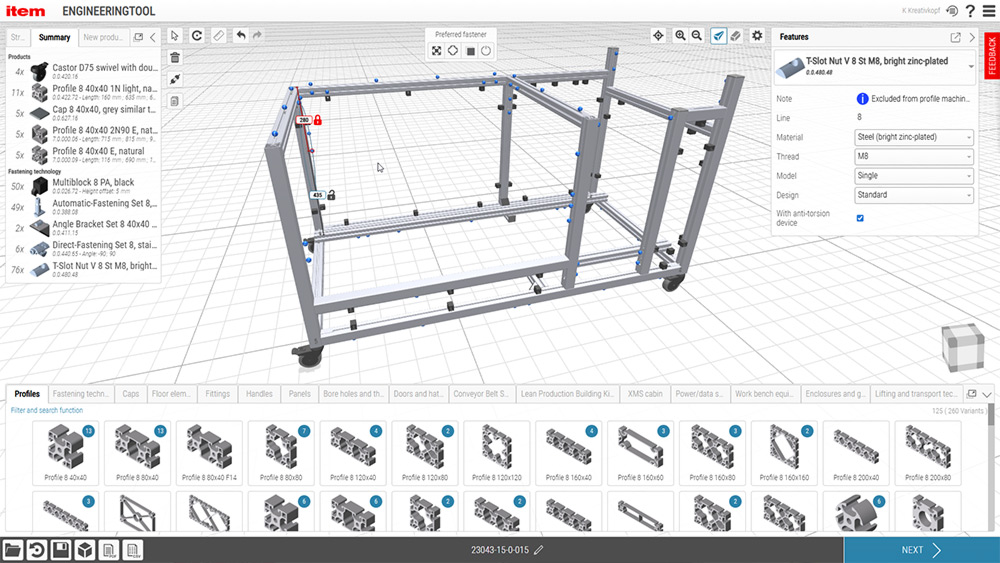

Getting to the finished solution faster with the item Engineeringtool

AXIAL’s use of the item Engineeringtool and the start of its item pluspartner relationship played a key role in the sheet stacker’s development. The frame was designed in the item Engineeringtool – including a 3D model, parts lists and production documentation. “We were able to go directly from the design to the ordering process with just a few clicks of the mouse. That’s obviously a big advantage,” emphasises Hoppe. You, too, can benefit from the possibilities of the item Engineeringtool and plan all kinds of constructions directly in your browser – wherever and whenever you want. The automatic placement of fasteners makes life even easier, as do integrate collision checks. “We also found the item Engineeringtool training sessions particularly helpful,” adds Hoppe.

For decades now, AXIAL Ingenieure has been using aluminium profiles from the item Building Kit System for a variety of constructions. Becoming an item pluspartner was therefore the next logical step in the collaboration. “The item pluspartner network meetings are particularly interesting. You come into contact with different companies and people, get chatting and can develop new ideas for potential joint projects,” reveals Hoppe.

Do you want to keep up to date on the various ways that item products are being put to use? Then we have just what you’re looking for! Simply subscribe to the item blog by completing the box at the top right.