Picture yourself in a state-of-the-art room, surrounded by white – from walls to ceiling …

In the background, you can hear the continuous soft whirring of the ventilation system. Rooms of this kind are used for everything from developing vital medicines and making complex semi-conductors to testing the next Mars rover. What looks like a normal room at first glance turns out to be a precisely planned cleanroom. What exactly is a cleanroom, though? It’s a space where the number of airborne particles is kept to a specified, low level to protect sensitive production processes and products from contaminants. The cleanroom class according to DIN EN ISO 14644-1 tells you the particle concentration that is permitted in a cleanroom. Read on to explore the possibilities of cleanroom construction and discover how the modular item Building Kit System offers optimum support.

System solutions for cleanrooms

Use the modular design principle to create dependable cleanroom solutions! Whether you need a cleanroom tent, a work bench with laminar flow box or a walk-in cleanroom cabin, item will help you implement solutions in exactly the dimensions required.

Advantage of the item Building Kit System in cleanroom construction

Our Line X and Line XMS aluminium profiles provide the ideal basis for all kinds of cleanroom solutions. They feature excellent resistance to chemicals, minimal edge radii and smooth, unbroken outer surfaces that make them exceptionally easy to clean. Their smooth sides and gap-free joins, where no airborne particles can accumulate, facilitate cleanroom construction. Thanks to the modular building kit principle, you can design solutions that meet your exact requirements. You can also modify and extend these solutions at any time. Use Fixing System X 8 as a panel fastening system for cleanroom walls or ceilings. In conjunction with high-quality, easy-to-clean panel elements, this creates flush transitions.

The filter fan unit with HEPA Filter H14 removes 99.995 percent of all particles from the air.

Various wall types (single skin, double skin or sandwich design) are possible. Profile X 8 240×40 1NO light can be used to create self-supporting ceilings up to six metres wide. Ceiling Holder Profile X 8 is used to secure ceiling elements in place, ensuring a high load-carrying capacity. You insert infills and filter fan units from above. A filter fan unit (FFU) is essential to ensure the cleanroom contains low-particle air. Together with the pre-filter and HEPA filter, FFU Housing 1200×600 forms a perfect unit. Our filter fan unit with HEPA Filter H14 removes 99.995 percent of all particles from the air. Stainless steel Perforated Sheet St 3mm is a good option for directing the laminar displacement flow from the FFU in a targeted way. Fixing System X 8, to which this sheet is attached, comes into play again here.

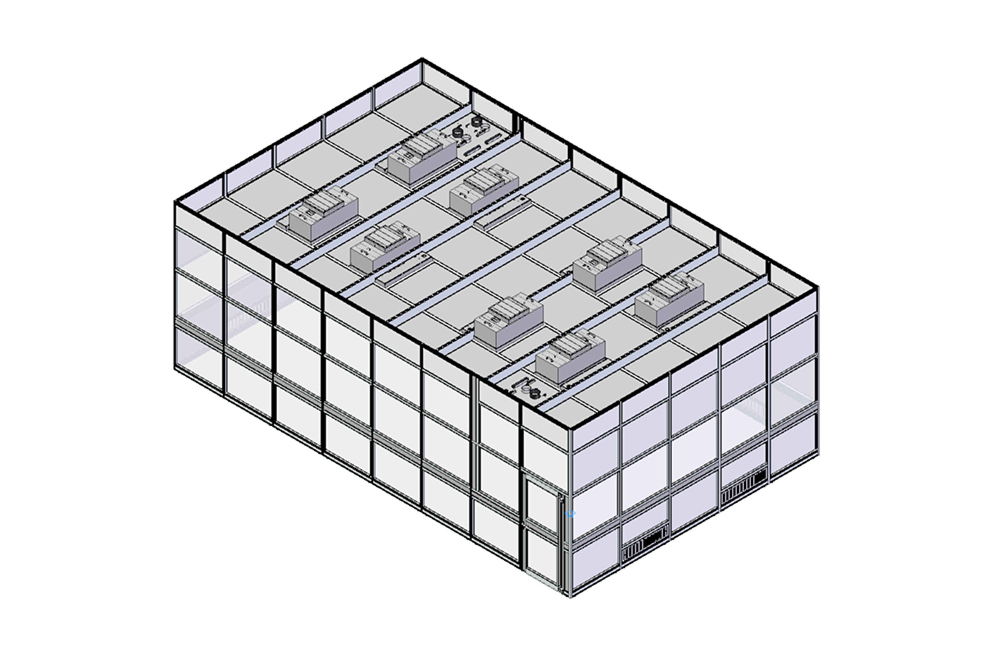

Planning and assembly of walk-in cleanrooms

Walk-in cleanrooms are one of the best-known clean production solutions. They offer you a great deal of scope when it comes to creating a controlled production and working environment. Take the example of our sample solution for a spacious walk-in cleanroom (9.6 x 6 m). Flush cleanroom walls make cleaning easier and prevent dust from accumulating. Eight filter fan units are located in an open plenum, and the entire ceiling can be walked on during maintenance work. The combination of Profile X 8 240×40 1NO light, Ceiling Holder Profile X 8 and Compound Material HPL 36mm results in a load-carrying capacity of over 2 kN/m2, which exceeds the capacity of 1 kN/m2 specified by DIN EN 1991-1.

Wall trunking facilitates safe, concealed cabling within the wall.

Our modular wall trunking facilitates safe, concealed cabling within the wall. With a clearance of 20 mm, you can lay cables over profiles without any need for machining. Sockets, switches and network connections can simply be clipped into place between two sections of wall trunking profile. Thanks to ready-made corner elements, you can lay cables to any point in a walk-in cleanroom. You can also switch from vertical to horizontal sections and back again. It is important always to maintain a slight overpressure in cleanrooms to help stop contaminants getting in from outside. Adjustable Ventilation Grilles 8 are used to regulate the internal pressure. Access Door 8 closes securely, can be used from either side and has an all-round seal. You will find this door in the item Online Shop in standard dimensions (with the hinges on the left or right), or as a solution you can configure yourself.

A different approach to cleanrooms – laminar flow boxes, partial enclosures and process enclosures

Building a large cleanroom isn’t always the ideal solution. What if cleanroom technology is only needed in certain production areas, or production space is already limited? Cost-efficient alternatives known as mini-environments are available for such cases. One example is a laminar flow box with height-adjustable work bench. You can use this cleanroom workstation for efficient and ergonomic production under clean conditions up to ISO class 5. A stainless steel perforated sheet acts as a working surface, ensuring the low-turbulence displacement airflow in the laminar flow box can be routed away without disturbing particles. You can add pivot arms to the work area for efficient material supply and tool storage. Comprehensive ESD protection is also possible.

If a laminar flow box is too small for your production steps, a partial cleanroom enclosure is recommended.

The laminar flow box is available as a flexible table-top unit, too. The hood with filter fan unit is then only used when absolutely necessary. If a laminar flow box is too small for your production steps, a partial cleanroom enclosure is recommended. Several filter fan units can be integrated into the ceiling to ensure a constant displacement flow through the entire area. You can use machine cabins for clean production to meet even more stringent air purity requirements. The FFU’s uniform displacement flow passes through the work area. It then reaches the lower level through a panel of perforated sheet and is fed back to the FFU via the rear wall. The use of Line XMS profiles with integrated cable conduits makes laying cables much easier.

Expertise in cleanroom tents for mobile and stationary use

Unlike hardwall solutions such as cleanroom cabins, a cleanroom tent doesn’t have rigid walls. That makes it one of the softwall solutions for cleanroom construction. The absence of rigid walls makes cleanroom tents an economical option and, in particular, a flexible one. A cleanroom-compatible workbench can be transferred inside. People can also enter and leave the tent. Optional swivel castors create a mobile solution. Otherwise, knuckle feet are used. However, cleanroom tents are not a direct alternative to closed cleanroom cabins. They aren’t suitable for processes that require a high level of purity, but they can be used for tasks such as simple assembly work and gluing. Cleanroom tents with strip curtains normally correspond to high DIN EN ISO 14644-1 cleanroom classes (> ISO 6). The higher the cleanroom class number, the more particles are permitted in the air.

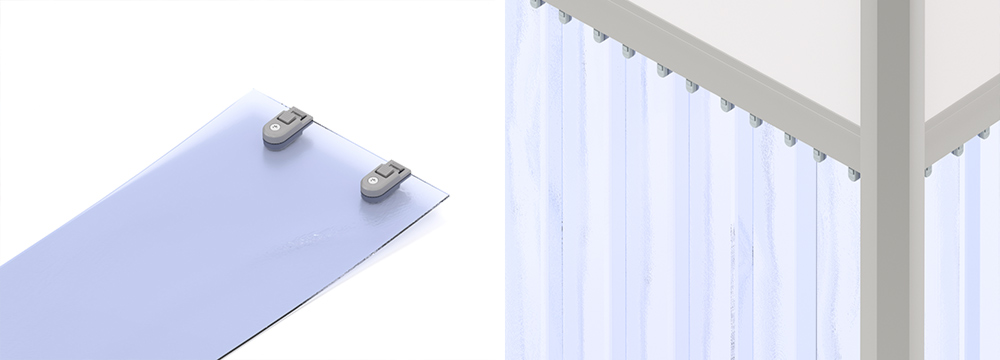

Our specially developed strip curtain comes into its own for cleanroom tents.

A frame forms the base of a cleanroom tent, and a ceiling construction is connected to this. Made from Plastic Pro panels, the ceiling accommodates one or more filter fan units as well as lighting. Overlapping strip curtains are used as wall elements. This is where our specially developed strip curtain comes into its own. Each strip installation consists of two strip holders and one PVC strip. The PVC strips are up to 2 mm thick and are available as cut-offs or as a 50-metre roll that can be cut to size as required. To create a strip curtain, you simply need to clip the strip holder into a Line 8 groove. It is also incredibly easy to take down and replace curtains.

Would you like to keep up to date with developments relating to cleanrooms? Simply subscribe to the item blog by completing the box at the top right.