“Over the past 30 years, the item Building Kit System has established itself as THE profile system for cleanroom technology,” says Joachim Ludwig.

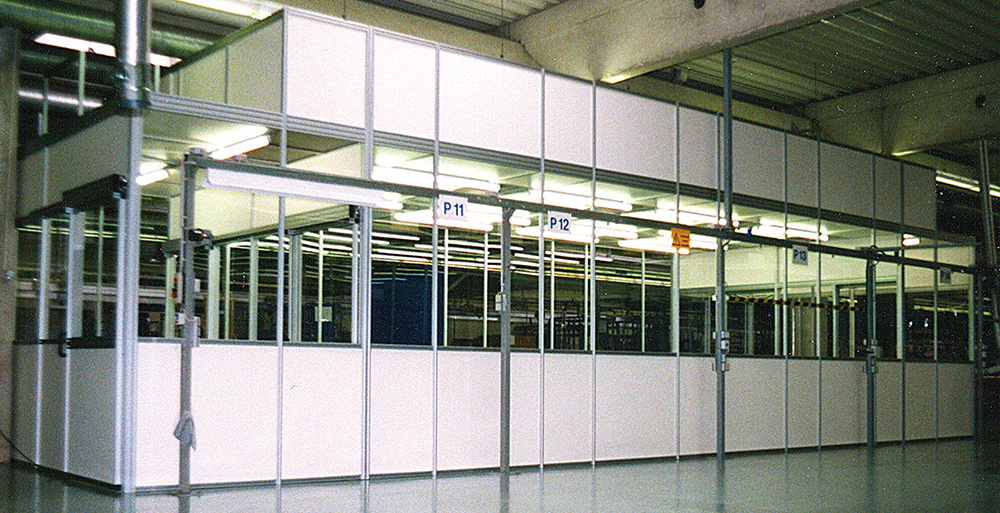

Joachim Ludwig and his daughter, Ina Henze-Ludwig, are the joint managing directors of COLANDIS GmbH. This company, which is a member of the item pluspartner network, develops and implements customised cleanroom technology and contamination control solutions. Right from the outset, Joachim – and, later, COLANDIS GmbH – used the item Building Kit System to build both simple and complex solutions. Ever-growing demands in the semiconductor industry, especially from the mid-1990s onwards, meant that new, innovative solutions were called for – and COLANDIS, which is based in the German town of Kahla, has developed and implemented exactly the kinds of solutions needed. By continuously developing and expanding its portfolio, item has also greatly extended its range of possible applications. Extending way beyond work benches and racks, the item portfolio offers a huge variety of solutions ranging from machine bases, conveyor systems and clean-air work benches to cleanroom cabins and walk-in cleanrooms. The first cleanroom made from item Building Kit System components was built in Lüneburg back in 1999. Measuring 50 m², the design included one staff airlock and two material airlocks in the ISO 7 air cleanliness class (which was still known as class 10,000 at that time).

As a system integrator, COLANDIS has been using item profile technology to build its contamination control solutions ever since 1995. This makes the COLANDIS team based in Kahla, Thuringia, very much pioneers in this field. “Nowadays, almost all suppliers use aluminium profile systems to build small to medium-sized cleanroom solutions,” Joachim explains. Besides needing suitable profiles as basic construction materials, contamination control applications also require a supply of clean air. This is where fan filter modules or fan filter units (FFUs) come in – a technology that has been in use for many years.

COLANDIS has developed its own FFUs that are particularly compatible with aluminium profile technology. And that’s not all – they’re different from other FFUs available on the market in other respects, too. All modules can be custom-designed, so there are many different variants. As these variants can also be combined in lots of new ways, requirements can be optimally met. This is a perfect illustration of just how adaptable the item Building Kit System and the COLANDIS FFUs are – and everything comes down to providing the best solution for the customer.

System solutions for cleanrooms

Use the modular design principle to create dependable cleanroom solutions! Whether you need a cleanroom tent, a work bench with laminar flow box or a walk-in cleanroom cabin, item will help you implement solutions in exactly the dimensions required.

Fan filter units (FFUs) – challenges and solutions

1. How can the compact design of FFUs be combined with aluminium constructions?

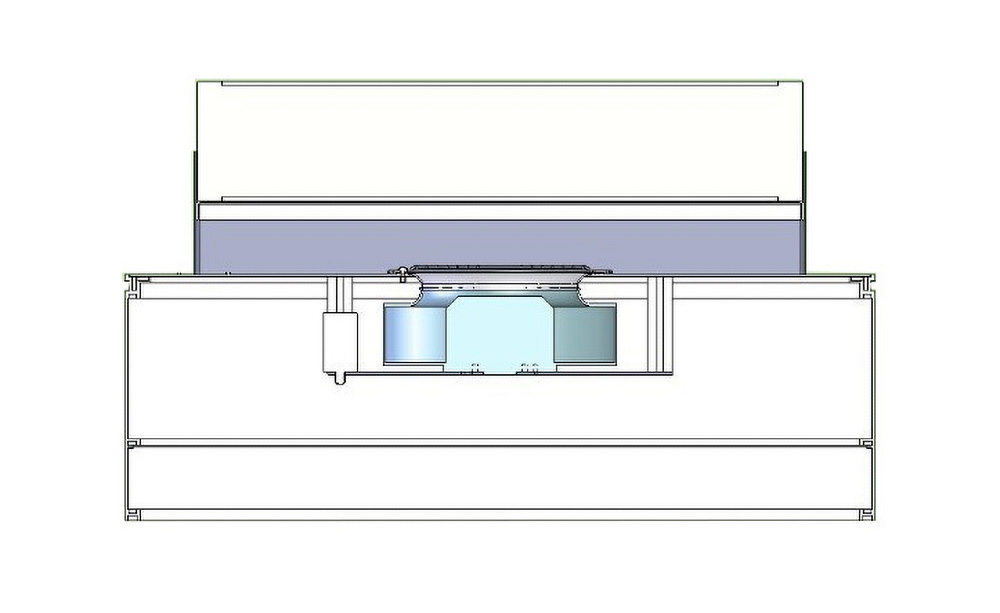

COLANDIS uses a patented filter element, which is designed such that the filter frame also serves as the housing frame for the entire module.

This also means the design of the modules matches the item Building Kit System perfectly. Practically all the surfaces are anodized, which results in a seamless appearance.

2. What should you do if the weight of FFUs limits the span in self-supporting constructions and makes assembly more difficult?

Thanks to minimal material usage, the COLANDIS FFUs are particularly lightweight. This means constructions can be built that are lighter and more efficient with a bigger free span.

3. How can FFUs be used for a horizontal airflow?

FFUs can be installed vertically (vertical airflow) in cleanroom ceilings, but that’s not the only option. They can also be used for applications with a horizontal airflow (and any other airflow direction is also possible). What’s more, there’s no longer any need to worry about the connection between the fan unit and the filter.

With a COLANDIS FFU, you can create a horizontal airflow – or direct the airflow any way you like.

Whether it’s a case of clean-air work benches or mini-environments, an optimised airflow, such as a horizontal one, is often better than a vertical one. When staff carry out a procedure, there is less chance that their hands will contaminate the product – instead, the airflow transports the contaminants to the outside or into a non-critical area by the shortest possible route.

A horizontal airflow often results in a better flow of air around the product – backflow areas (where turbulence is generated) are avoided.

4. When you build a cleanroom cabin inside an existing room, you’re limited in terms of overall height and therefore in terms of the ceiling height of the cabin. Is there a solution to that?

Yes, there is. The reason why these heights are limited is that most FFUs available on the market have a construction height of 400 mm (or up to 600 mm if there’s a prefilter, too). However, the COLANDIS FFU is just 200 mm tall, or 300 mm if it has a prefilter.

If a cleanroom and/or cleanroom cabin is being retrofitted inside an existing room, you’re often limited by the ceiling height of that room. That prevents the use of many modules that are available on the market.

If you have an existing room height of 2.80 m and an FFU with a height of 400 mm, that means the ceiling height in your cleanroom or cleanroom cabin has to be under 2.40 m. However, workplace regulations drawn up by Germany’s accident insurers (Arbeitsstättenrichtlinie) stipulate a minimum height of 2.50 m for rooms of up to 50 m².

As room dimensions increase, the prescribed room height does, too. However, a COLANDIS FFU without a prefilter could be used in that scenario.

The item Building Kit System is the system that is used most frequently for retrofit situations – and the perfect interplay between item profile technology and the COLANDIS fan filter modules is a real bonus.

5. What cleanroom solutions and FFUs are available for the most stringent cleanliness requirements, e.g. in the semiconductor industry?

Aluminium constructions are very often used for applications in high-tech industries. These include the semiconductor industry and similar sectors such as optics and sensor technology. For example, requirements in the semiconductor industry include:

- A U16 filter (removes 99.99995 percent of airborne particles)

- Materials containing minimal or no boron and with low outgassing rates (Fabsave)

In these respects, there is very little difference between the COLANDIS fan filter modules and other FFUs on the market. However, the COLANDIS Fabsave fan filter modules have a special feature – it is not only the filter of these products that is made with low-outgassing components. Instead, all the other assemblies and components, right down to the wire insulation, are designed to meet this requirement.

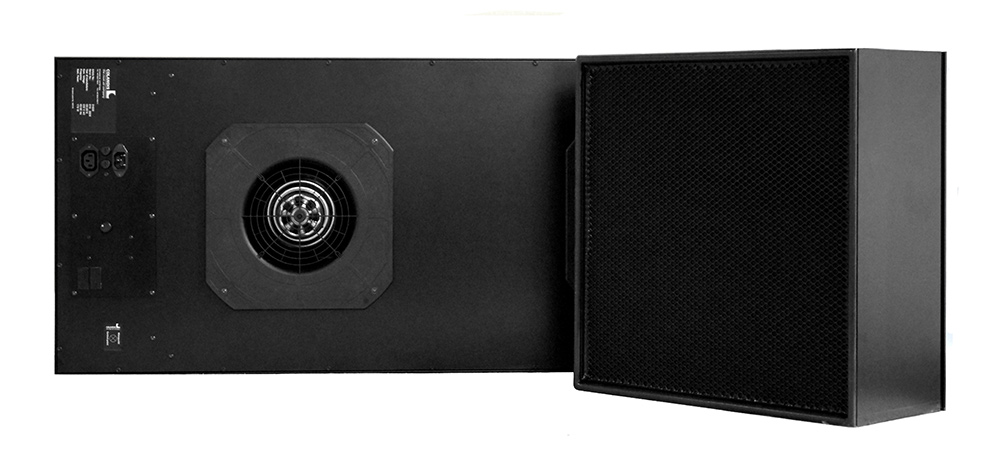

6. How do you prevent light scatter in the case of optic and laser applications in a cleanroom?

Black constructions are recommended as a way of preventing light scatter – and black profiles and panel elements from the item Building Kit System are ideal for building these constructions.

To ensure constructions are completely black, the fan filter modules and filter surfaces used need to be entirely black, too. Combining item components with the patented black fan filter modules from COLANDIS results in technical solutions that almost completely prevent the issue of light scatter.

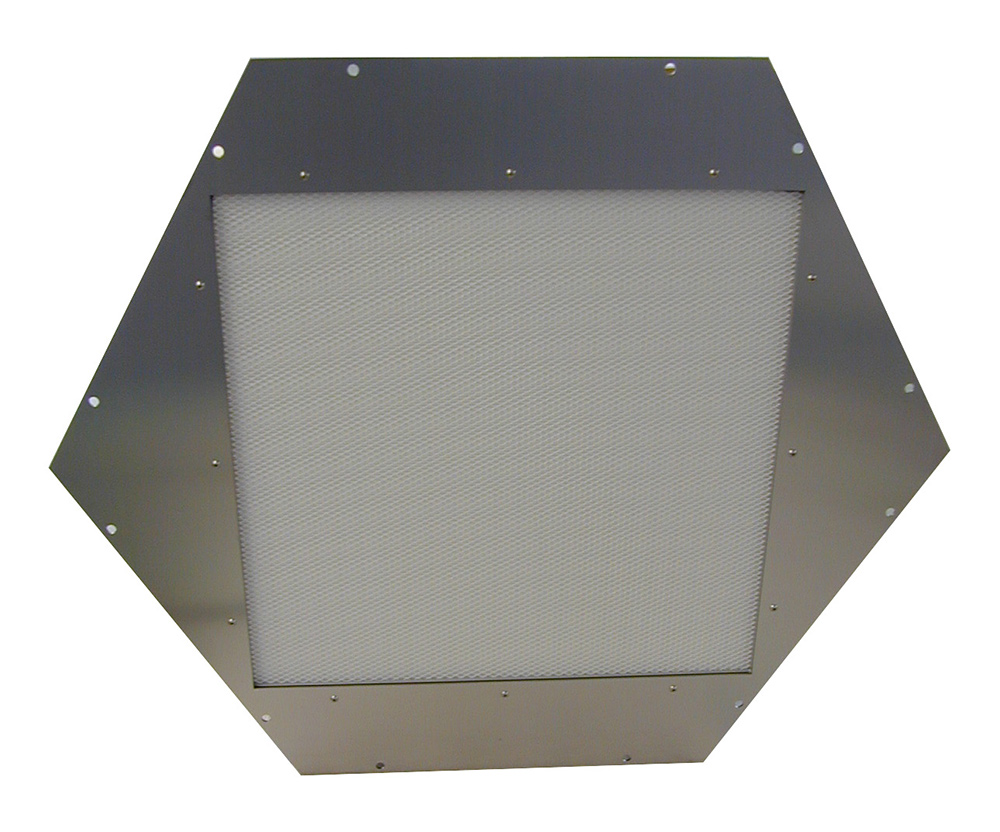

7. Are there fan filter units specifically for cluster tools?

Yes, there are. Cluster tools and their enclosures don’t have a square footprint – they tend to be hexagonal or octagonal instead. When it comes to building these kinds of machine enclosures, Line XMS profiles are the ideal solution.

COLANDIS offers plug-and-play components for building solutions efficiently and cost-effectively. Thanks to the customised basic frame, additional functions such as ionisation systems and lighting can be integrated in advance. This makes the installation in the relevant cluster tool much more straightforward.

8. How flexible are FFUs in terms of size and shape?

COLANDIS supplies its FFUs in a wide range of standard sizes, so optimum cleanliness conditions can be achieved with a large filter surface. ANY reasonable size and shape is basically possible. Simply get in touch with the COLANDIS team.

Would you like to keep up to date with developments relating to cleanrooms? Simply subscribe to the item blog by completing the box at the top right.