A guard for industrial use must have a standard-compliant design. Read on for details of the relevant requirements.

What you need to know about constructing standard-compliant safety fixtures:

– According to the Machinery Directive, only machinery that is safe and has a corresponding CE marking can be brought into circulation. A risk assessment based on DIN EN ISO 12100 indicates whether a guard is required for this purpose.

– DIN EN ISO 14120 is the key standard when designing safety guards. It covers aspects such as load capacity, i.e. impact resistance, and protection against tampering.

– DIN EN ISO 14119 specifies the interlocking devices that are required for the guard’s door openings.

– The safety-specific standard DIN EN ISO 13857 deals with safety distances in hazard zones.

– item has put a lot of thought into its configurable guard elements to help you design standard-compliant safety guards.

Simply use the configurator in our Online Shop and the item Engineeringtool to customise the relevant element to your requirements without compromising its conformity

What is the link between the Machinery Directive and the process of designing safety guards?

Machinery Directive 2006/42/EC is used to decide whether a machine requires a safety guard. According to the Machinery Directive, only machinery that is safe can be used in production operations and this machinery must have a corresponding CE marking.

The CE marking indicates that the relevant machine meets European safety standards, which provides you with the legal certainty you need as the machine operator. A machine often requires a safety fixture to qualify for the CE marking.

A machine undergoes a risk assessment to decide whether it is sufficiently safe. You will find details of how to carry out this risk assessment in DIN EN ISO 12100. If the assessment indicates that design measures alone are not sufficient, a further safety measure is called for. An additional safety fixture must then be built in line with the relevant standards.

The relevant standards for designing guards are as follows:

– DIN EN ISO 14120

– DIN EN ISO 14119

– DIN EN ISO 13857

Key considerations when designing safety guards

In the item Academy, you will find detailed information about what you need to bear in mind when designing guards. The relevant online training module sets out the key considerations step by step.

What are the requirements of DIN EN ISO 14120 when designing a safety guard?

DIN EN ISO 14120 is the key standard relating to the design of safety guards. It provides general information about what you need to bear in mind when designing a guard, including criteria such as impact resistance and protection against tampering.

Generally speaking, a safety guard should ensure staff can’t access the hazard zone or be put at risk if hazardous materials escape. The impact load the guard needs to withstand from both the outside and the inside must therefore be considered during the design process. If solid panels are incorporated, the safety guard also offers protection against escaping hazardous materials such as emissions or liquids.

What impact loads must a safety guard withstand?

According to DIN EN ISO 14120, a safety guard must withstand 115 Joules when a person or object weighing 90 kg collides with it at a speed of 1.6 m/s. For example, it must not give way if a person moving at walking pace trips over and falls against it. Since people move around production departments not only on foot, but also using scooters and other vehicles, companies sometimes require solutions that withstand higher impact loads. The standard requirement in this case is 329 Joules.

If your requirements exceed this level, item components with a maximum impact resistance of 767 Joules are available. When using Clamp Profile 8 40×40, the panel element is screwed into the profile. Safety guards built using this profile withstand high impact loads of up to 767 Joules and are easy to assemble and dismantle.

A removable guard element must be designed in such a way that it does not retain its protective function when detached.

What are the provisions of DIN EN ISO 14120 regarding protection against tampering for safety guards?

If periodic maintenance work needs to be carried out on machinery, detachable panels can be installed in the safety guard to provide access. In such cases, DIN EN ISO 14120 specifies the requirements relating to these panels. A removable guard element must be designed in such a way that it does not retain its protective function when detached.

It must be immediately apparent that the guard cannot perform its protective function at that particular point in time. What’s more, some kind of tool must be needed to detach a removable guard element.

item hangers are an ideal solution. As soon as the detachable panels are unscrewed at the top, they tip forward slightly and you see straight away that the safety guard is no longer performing its protective function.

Doors are often installed in safety guards instead of maintenance hatches. To ensure the machine remains safe in line with the Machinery Directive and the safety guard retains its protective function, the door must have an appropriate interlocking device. DIN EN ISO 14119 defines when an interlocking device is required and what type of device in each case.

What does DIN EN ISO 14119 stipulate regarding interlocking devices?

DIN EN ISO 14119 stipulates what kind of interlocking device must be in place on a door in order for a safety guard to retain its protective function and the machine to remain safe. Several options are available:

– If the machine stops as soon as the door is opened, a simple interlocking device is sufficient.

– If a machine takes time to stop, an interlocking device with guard-locking function is required. The guard-locking function is deactivated as soon as the machine has stopped.

– You can also use an interlocking device with a guard-locking function if you want to actively prevent the machine from stopping when the door is opened. This is a particularly good idea for processes such as regular quality controls.

What aspects of designing safety guards does DIN EN ISO 13857 cover?

The safety-specific standard DIN EN ISO 13857 deals with safety distances in hazard zones. Its purpose is to prevent people from accessing the hazard source.

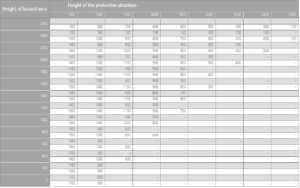

The correct safety distance primarily depends on the position and size of the hazard zone and the height of the safety fixture. The mesh width and the size of outlets also play a key role.

The lower the safety guard and/or the larger the mesh width, the further staff can extend their arms and/or tools into the hazard zone and the further the safety guard must therefore be from the hazard source. A higher safety guard limits the area that can be accessed, meaning the safety guard can be closer to the hazard source.

DIN EN ISO 13857 also defines the permissible mesh width of a safety guard. Corrugated mesh and steel mesh from item with a 40 mm mesh width prevent limbs from passing through the safety guard. The distance between the guard and the ground is stipulated in DIN EN ISO 13857. At item, we use a fixed distance of 170 mm to comply with this stipulation.

How does item help with the task of designing standard-compliant safety guards?

All components and safety guards in our product portfolio undergo a stress test to check their impact resistance. You can therefore rest assured that your safety guards will be sufficiently robust. Ready-made guard elements make it easier for you to design standard-compliant safety guards.

You can use the configurator in our Online Shop to customise these elements to your specific requirements in terms of impact resistance and dimensions. The configurator will then automatically select the right components to ensure a standard-compliant solution. In the item Engineeringtool, you can then use your customised components to create a complete safety guard and, if necessary, add other equipment.

Questions about designing standard-compliant safety guards

When is a safety guard required according to the Machinery Directive?

A safety guard is required when design measures are not sufficient to guarantee machine safety. A risk assessment as specified by DIN EN ISO 12100 determines whether a safety guard is required.

What standards need to be complied with when designing safety guards?

The key standards when designing safety guards are as follows:

– DIN EN ISO 14120: Contains stipulations relating to the general design of safety guards, including criteria such as load capacity, i.e. impact resistance, and protection against tampering.

– DIN EN ISO 14119: Defines requirements relating to interlocking devices for safety applications.

– DIN EN 13857: Deals with safety distances to the hazard zone.

What impact load does a safety guard need to withstand?

The impact load a safety guard needs to withstand depends on the relevant requirements. DIN EN 14120 stipulates that the safety guard must withstand 115 Joules when a person weighing 90 kg collides with it at a speed of 1.6 m/s (e.g. tripping over at walking pace). Many production companies in sectors such as the automotive industry require solutions that withstand a higher impact load. The standard requirement in this case is 329 Joules. item offers safety guards that withstand impact loads of 115 Joules, 329 Joules or 767 Joules.

What are the provisions of DIN EN ISO 14120 regarding protection against tampering?

DIN EN ISO 14120 stipulates that removable guard elements need to be designed in such a way that it is obvious when they are detached and no longer retain their protective function. Some kind of tool must be needed to detach a guard element.

What safety distances are stipulated in DIN EN ISO 13857?

According to DIN EN ISO 13857, the safety distance between the safety guard and the hazard source depends on their respective heights. The higher the safety guard, the shorter the distance to the hazard source can be.

What are the key criteria when selecting an interlocking device for the door of a safety guard?

If a door is installed in the safety guard, DIN EN ISO 14119 stipulates that this door must have an interlocking device. Two main options are available:

– Simple interlocking device: If the machine stops immediately as soon as the door is opened.

– Interlocking device with guard-locking function: If the machine continues running after the door is opened or only certain team members should be able to open the door. The guard-locking function is only deactivated once the machine has stopped.

How does item help with the task of designing safety guards?

item offers ready-made guard elements that you can easily customise using the configurator in the item Online Shop. It also ensures that these elements are standard-compliant solutions. In the item Engineeringtool, you can use your customised guard elements to create a complete safety guard. All components have undergone a stress test to check their impact resistance.

Would you like to keep up to date with developments relating to safety guards? Simply subscribe to the item blog by completing the box at the top right.