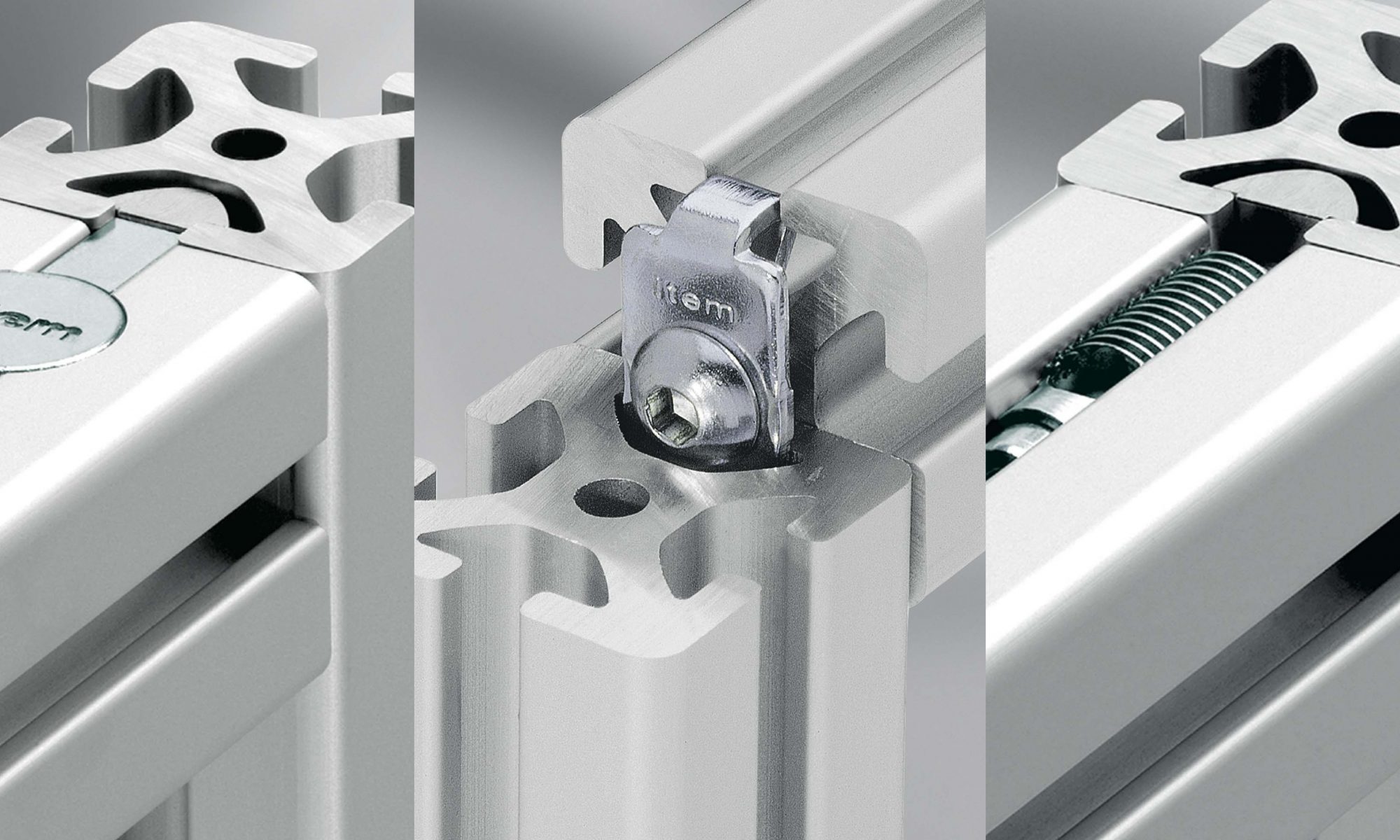

Stable, reliable, versatile – the aluminium profile fasteners from the item MB Building Kit System offer solutions for any application.

Even under heavy loads, the innovative fastening technology from item ensures a reliable hold for your aluminium profile constructions. However, depending on the application, certain aluminium profile fasteners will be more suitable than others. For example, when building prototypes and constructions that will be put together and taken apart again on a frequent basis, extendibility and flexible connections will be more important than high load-carrying capacity and low machining requirements. However, when it comes to permanent, standardised constructions that you require in several variants, the priorities are cost savings and rapid assembly. In this post, we will show you how to achieve typical fastenings.

Are you new here? This is the MB Building Kit System.

Flexible, robust and high-quality – the item MB Building Kit System has been the optimum solution for all design and construction tasks in mechanical and factory equipment engineering for over 40 years.

FIND OUT MORE

Aluminium profile fasteners for fixed connections at a 90° angle

The Standard-Fastening Sets offer a perfect solution for connecting profiles in permanent, fixed positions. They provide outstanding resistance to displacement and torsion. These aluminium profile fasteners are remarkable for their low machining requirements and cost-effectiveness. When using the one-sided variant of the Standard Fastener, panels don’t need to be specially machined before they can be fitted into the groove. It is available for Lines 5, 6, 8, 10 and 12.

The correct aluminium profile fastener for right-angled, movable connections

The Universal-Fastening Set is ideal for retrofitting to existing constructions. Its unique features include combining high load-carrying capacity with movability and flexibility and its suitability for retrofitting. This only requires two stepped bores in the aluminium profile to be added (profile B). The aluminium profile fasteners can be pre-positioned in the groove of profile A. They can then be pushed into the stepped bores on profile B and tightened in one simple step. Once attached using the Universal Fasteners, profile B can be moved along the profile groove. Universal-Fastening Sets are available for Lines 5, 6, 8, 10 and 12.

Create right-angled, movable connections without profile machining

If you are looking to create a strong, movable, right-angled profile connection fast, then the Automatic-Fastening Sets are just what you need. When it comes to assembly, the huge advantage of these is that absolutely no machine-based profile machining is required. The fasteners are screwed directly into the groove, at the end face of profile A. T-Slot Nuts are inserted into the groove of profile B, and the aluminium profile fasteners from profile A are then screwed into these. Since assembly is so fast and there is no need for profile machining, Automatic Fasteners are ideal for retrofitting to an existing construction. They are available for Lines 5, 6, 8, 10 and 12.

More video instructions for perfect connections

Find out more for free: In the item Academy, you can find more video instruction guides for installing products and online training courses on subjects such as “Lean production”, “ESD” and “Value-stream mapping”.

FIND OUT MORE

Butt fasteners in three variants

There are two solutions for connecting together identical, colinear item aluminium profiles via their end faces. The Universal-Butt-Fastening Set is attached using one stepped bore per profile, and provides a connection with a high load-carrying capacity. It is available for all lines. The Automatic Butt-Fastening Set offers an alternative for Lines 5, 6, 8 and 12. No profile machining is required for this, which keeps assembly work to a minimum. Two profiles from the same Line (6 or 8) mitred at the same angle can be connected using a Mitre-Butt-Fastening Set. This can also be used to fasten mitre cuts to a closed frame.

Connecting profiles that cross each other

If you are intending to connect together crossing Line 8 aluminium profiles, you can use the Click-Fastening Sets. They can be fitted in any position along the groove particularly fast. Adjusting the angle or position and dismantling the connection is quick and easy – simply loosen and retighten the Hexagon Socket Head Cap Screw. Alternatively, the Direct-Fastening Sets are also suitable for friction-based connections where the profile sides touch. Neither the Direct-Fastening Sets nor the Click-Fastening Sets require any profile machining and both can therefore be retrofitted to existing constructions.

Connecting together Profile Tubes and connecting to Profile Tubes

Profile Tube System D30 from item is perfect for building factory equipment fast and implementing lean production concepts. The associated fasteners enable you to establish strong connections – whether you are aiming to connect smooth Tubes or Profile Tubes. The D30 fastening elements also provide exceptional tolerance compensation. The tubes can be cut up to 5 mm shorter without reducing the holding force of the connection. Furthermore, the fasteners automatically create a contact between the components that safely dissipates harmful electrostatic charges – ESD protection is therefore built-in. In addition, Fasteners D30 allow users to combine Profile Tubes with standard profiles. No additional machining has to be carried out on the Tubes or profiles in order to use the fastening elements.

Rotating right-angled connection – the aluminium profile fastener that clicks

The item Click-Fastening Set 90° for Line 8 is a speedy solution for making a right-angled profile connection at any angle of rotation. The connection can subsequently be moved and retrofitted to existing structures, making it ideal for flexible constructions such as prototypes and temporary structures. Click-Fastening Set 90° is attached to the end face of a profile via a threaded bore, meaning profile A can simply be clicked into profile B and tightened. When building permanent structures, Direct-Fastening Set 90° is a better option. This fastener also uses an end-face threaded bore to connect the end face of profile A directly to the grooved side of profile B. Both fasteners are available for Line 8.

Other aluminium profile fasteners and applications

These fasteners already cover a broad range of applications, but it goes without saying that there are plenty of other ways of connecting together aluminium profiles and other elements of the MB Building Kit System. Go to our Online Shop for fasteners to discover more options.