Unlike many other methods of lean production that began taking the world by storm in the 1990s, Karakuri/LCA is a relatively unknown concept in Europe.

LCA stands for “low-cost automation”, which is a lot clearer than the Japanese term “Karakuri”. “Karakuri ningyō” can be translated as “mechanical doll” and represents a long tradition of Japanese culture, involving everything from stage equipment to tea butlers. But there is one thing they all have in common – they all centre around a purely mechanical form of automation. In other words, industrial Karakuri/LCA applications do not use any pneumatic, electrical or hydraulic drives. Instead, modern-day Karakuri relies exclusively on gravity and the resulting kinetic energy. In addition to being environmentally sustainable, this method of lean production is primarily characterised by its cost-effectiveness due to the fact that no electrical energy is used. For these and other educational reasons, Prof. Volker Ahrens from the NORDAKADEMIE Hochschule der Wirtschaft deals intensively with the topic of Karakuri/LCA. The automation laboratory run by the engineering department of this private University of Applied Sciences now has a Karakuri/LCA system made from Profile Tube System D30 provided by item.

The world of lean production

Less waste and more added value – lean production methods let you make targeted improvements to your production efficiency. Our white paper provides a concise introduction.

GET YOUR COPY NOW!

Focusing on the essentials with Karakuri/LCA

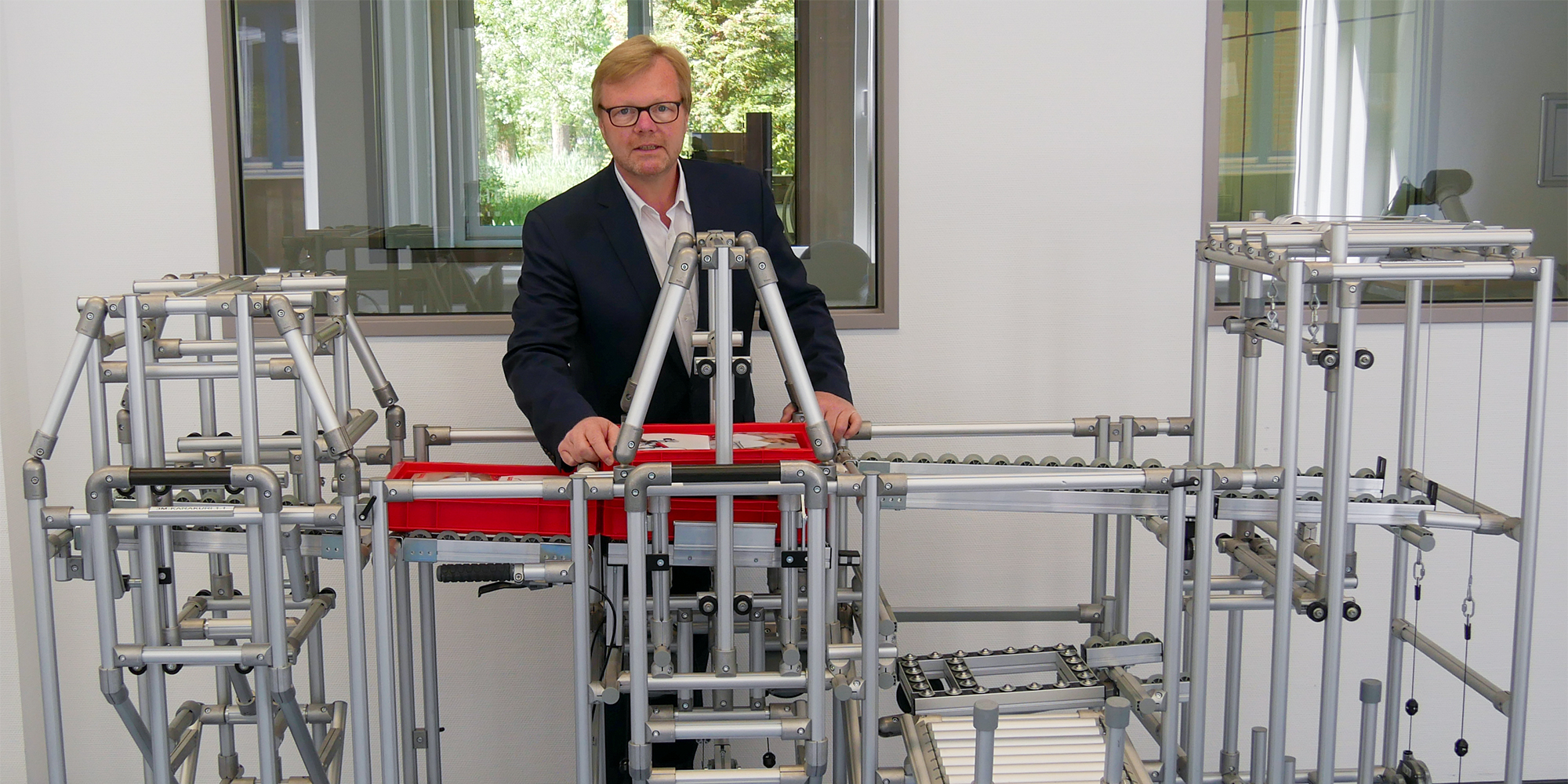

The focus of NORDAKADEMIE is decidedly practice-oriented. At undergraduate level, for example, this state-recognised university exclusively offers dual work/study programmes. On top of that, there are a number of collaborations with companies that also benefit the automation laboratory, which offers numerous practical examples of working with electrical drives, electronic controls, Industry 4.0 solutions and, most recently, mechanical automation using Karakuri/LCA. Of course, item was Professor Ahrens’ first port of call for this particular topic: “One thing’s for sure – when it comes to lean production, all roads lead to item.” What’s more, our ergonomics expert Marius Geibel was previously a guest lecturer for the chairholder for production management and head of the industrial engineering (B.A.) programme. Ergonomics and the design of work bench systems are also an integral part of the courses on offer.

Even the highly versatile automation laboratory is explicitly geared towards providing a holistic view. “We aim to teach the students a broad spectrum of topics. They are presented with a problem and then have to figure out how best to solve it. Which is better – the complex digital solution, a simple mechanical solution (i.e. Karakuri/LCA) or a hybrid solution that combines the two? That’s what we’re interested in,” explains Professor Ahrens. This is by no means his attempt to downplay the importance of advanced digital solutions. After all, collaborative robots and other high-tech applications can also be found in the automation laboratory. However, for this passionate university professor, it is about teaching his students to focus on finding solutions along the way and, despite all the justified enthusiasm surrounding future technologies, not losing sight of one key issue: “Engineers are problem solvers. They want to solve the problem as efficiently and effectively as possible.” Whether a digital solution or a “simple” one like Karakuri/LCA will lead to the desired outcome all depends on the particular challenge at hand. Would you like to know more about Karakuri/LCA? You can deepen your knowledge in a special online training at the item Academy.

Encouraging creativity and innovation

The aspects of Karakuri/LCA mentioned above are not the only ones that benefit Professor Ahrens’ work, though. The long-standing method of lean production is more than just a subject he covers in his courses. Since he is also conducting research into this topic, the Karakuri/LCA system from item is a key source of inspiration for him. The focus of this research, which is breaking new ground in the field of Karakuri/LCA, is the way in which objects stimulate creativity: “Objects have a unique characteristic that encourages actions that would not otherwise take place. So far, I have researched this with cardboard engineering, where students build true-to-scale solutions using cardboard. Playfulness and creativity go hand in hand here.”

With that in mind, Professor Ahrens is researching the extent to which working with Karakuri/LCA promotes innovation and creativity. The lean method goes even further than cardboard engineering, as it involves an actual operational system rather than a model. Industrial engineers also see an advantage here with regard to the continuous improvement process and employee participation. Being able to actively interact with this kind of system gives them a completely different relationship to their work and enables them to make improvements independently. And finally, there is another crucial aspect that cannot be overlooked either: “People’s eyes light up when they’re assembling this kind of system! They just really enjoy it.”

Are you interested in the applications and principles from the world of lean production? Then we have just what you’re looking for! Simply subscribe to the item blog by completing the box at the top right.