In the past, there was no getting around the fact that you needed wide-ranging coding skills if you wanted to program robots.

While lightweight robots such as cobots are easier to program, coding skills remain an obstacle for people and companies new to robotics – all the more so when it comes to conventional industrial robots. In terms of the integration of robotics, programming tends to be a major hurdle for SMEs. As a result, SMEs often still miss out on the many advantages of robots – such as greater efficiency in completing tasks that don’t add value or tasks that put particular strain on staff. The founders of Augmentus are only too well acquainted with these issues, as they were previously responsible for developing robotics applications in various companies. It was precisely these experiences that inspired the creators of the robotics platform that shares the company’s name to come up with an intuitive software solution that goes a long way towards breaking down these barriers. Right from the outset, they wanted to make robot programming accessible to all – in other words, no robotics experience or programming skills are required. This is possible thanks to a graphical user interface that is operated using a touch pen and tablet. Augmentus also offers turnkey robotics solutions based on the item MB Building Kit System.

Programming robots the easy way

Read our user report to find out all about the innovative Augmentus robotics platform and the turnkey solutions based on item profile technology. Robotics really can be this simple!

GET YOUR COPY NOW!

Robot programming made easy – and turnkey cobot solutions

The user plans the robot’s on-site path by plotting waypoints on the user interface. Alternatively, a templates’ library can be used to set up a motion profile. Artificial intelligence (AI) is then used to optimise the sketch of the application. Robots can therefore be programmed within a matter of minutes – for applications such as spraying, polishing, palletising or machine loading. Thanks to a common programming interface for all industrial and lightweight robots, Augmentus platform users can deploy different types and brands of robot in parallel. The software automatically translates the tablet input into programming languages such as RAPID, URScript and Karel. The code can be checked and adjusted at any time as needed. There are therefore no obstacles to selecting and setting up the appropriate configuration and thus getting started with the process automation more or less straight away – and all with minimal effort and outlay. Augmentus also supports the integration of additional components such as sensors, grippers, camera arrays and image processing systems.

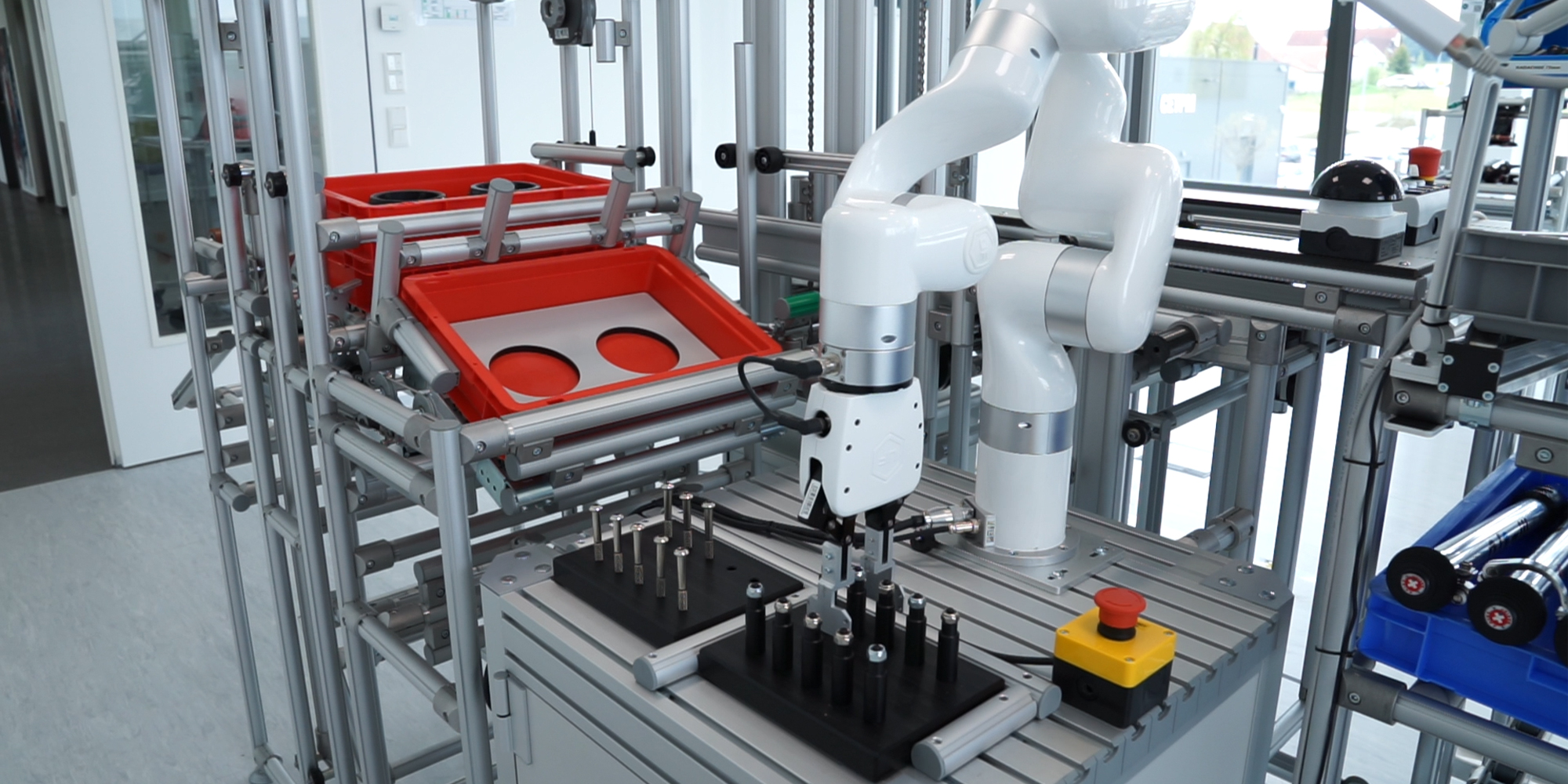

The aluminium profile technology from item – which is both lightweight and robust in equal measure – provides the perfect stable base for a mobile robot table.

Since cobots in particular are easy to reconfigure, it’s well worth using them even for relatively small batch sizes. They are already easy to program – but Augmentus makes the process simpler still. Alongside its software, the company offers turnkey solutions, since a mobile support structure for a cobot provides extra flexibility. Augmentus puts its trust in the item aluminium profile technology and the expertise offered by local sales partner Intermech for these solutions. Our aluminium profile technology – which is both lightweight and robust in equal measure – provides the perfect, stable base for a mobile robot table. Special Robot Mounting Plates, for example, can be screwed directly into the profile groove. The item Building Kit System offers a huge selection of components – more than 4000 of them – for designing customised robotics applications. For example, door and panel elements can be added to shield the control technology and cables underneath the mobile cobot table from the production environment. Given these many benefits, Augmentus intends to continue working closely with item and Intermech.