How process automation systems provide specific support for automotive suppliers, with machine cabins playing a key role.

The automotive industry is quite rightly regarded as a driving force in the history of robotics. After all, it was General Motors that first introduced the revolutionary Unimate industrial robot in 1961. The sector’s widespread use of robotics started in the 1970s and has continued ever since. In 2021, the prevalence of robots in the automotive sector was therefore some way ahead of other branches of industry. In Germany, there were 1311 robots per 10,000 staff. However, robotics in particular and automation in general are vitally important not just for car production, but also for the industry’s suppliers. They, too, face significant time and cost pressure. That’s why the Italian company Vensys has developed two special systems – a robot soldering station, and a machine to assemble and test electronic flasher units. A modular machine cabin based on Line XMS from item provides the necessary safety, flexibility and stability for each of these two projects

An overview of robot applications

Read our white paper to discover specific applications and other advantages of robotics in industry – and explore why lightweight robotics is a particularly worthwhile investment for small and medium-sized enterprises.

GET YOUR COPY NOW!

Ideal for soldering – robots in the automotive industry

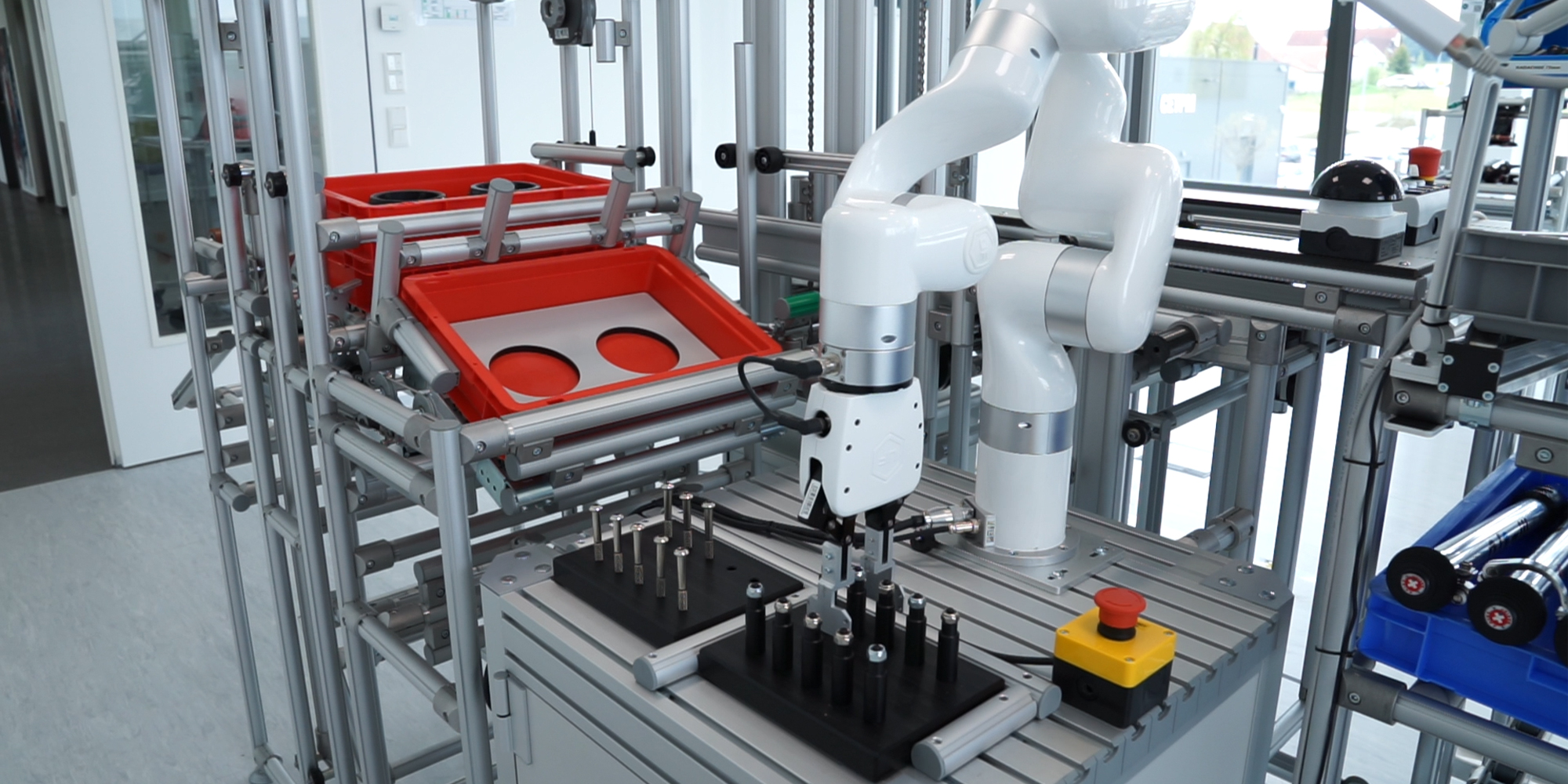

The young Italian company makes customised automation and robotics solutions for a variety of sectors. Its service portfolio covers everything from requirements analysis and troubleshooting to machine testing, machine maintenance and software development. Vensys was looking for a suitable base construction to implement the two solutions for automotive suppliers. “Aluminium was definitely the best material for our applications,” says the Vensys Project Manager, Nicola Zecchin. As part of the modular item building kit system for cobot solutions, Line XMS impressed across the board. Its low weight, stability and attractive design were the decisive factors for the decision-makers at Vensys. A four-axis SCARA robot from Epson (T3-B401S) is installed inside a machine cabin based on Line XMS. It was a practical problem that provided the impetus for this development. One frequent challenge for automotive suppliers is connecting the plugs and printed circuit board for clock relays. “One of our customers initially tried to solve the problem using a standard solution from its supply chain, but without success,” reveals Zecchin. The most efficient solution is automation in the form of robot soldering.

Aluminium was definitely the best material for our applications.

The automated soldering process works in exactly the same way as its manual equivalent. A hot iron tip at a temperature of 350 °C heats the area to be soldered. A thin tin solder wire with a diameter of 0.5 mm is used as a filler. Since the free-standing machine cabin incorporates not one but two guide rails, the robot can carry out two soldering processes one after the other – a perfect example of how using robots in the automotive industry specifically boosts efficiency. A small footprint and fast, accurate repeats make SCARA industrial robots ideal for automated soldering. What’s more, cobots can also be used for this task. Besides reducing cycle times between soldering processes, having the robot take care of soldering also minimises errors. This increases output, which makes production especially profitable. Further benefits include optimised solder consumption and the fact that operators don’t need any specialist training for this robotics application.

Line XMS protects staff

Soldering processes call for meticulous safety measures. They generate harmful fumes that must not be allowed to escape into the surrounding area, as this would represent a serious health risk to staff. The machine cabin is therefore completely sealed using a series-standard sealing system that ensures no toxic fumes are released. In addition, soldering fumes are immediately extracted, and the cabin effectively switches to “emergency mode” as soon as the side door is opened. “Line XMS from item gave us everything we were looking for,” reports Zecchin, who was also impressed by the wide range of Line XMS accessories. This extensive selection and the modularity of Line XMS offer Vensys all the design freedom it could wish for.

Line XMS from item gave us everything we were looking for.

Although the second Vensys automotive industry application doesn’t specifically use a robot, automation in general does play a part. The system in question assembles and tests electronic flasher units. Vensys is benefiting from the modularity and safety of Line XMS in this project, too. A rotary table with four workstations is installed in the machine cabin. During the process, the table turns so that the relevant flasher can be assembled, tested and labelled. Given that this automation solution had to be designed completely from scratch, it took around a year to get from the design stage to delivery. The mechanical and automation aspects were especially challenging. Not least thanks to the flexibility of Line XMS, though, it was possible to meet all the requirements. The customer feedback for both projects was extremely positive. “Our customers are very appreciative. The item products are extremely robust and well thought out,” says Zecchin.

Want all the latest updates on innovative robotics applications? Then we have something that’s right up your street! Simply subscribe to the item blog by completing the box at the top right.