With its innovative punching system, item pluspartner ERWEMA is demonstrating how automation accelerates processes and lightens the load on staff.

How can sheet metal machining companies meet growing requirements in terms of precision, efficiency and flexibility – and at the same time ease the burden on their staff? The answer lies in automating processes. ERWEMA GmbH offers an excellent example of how this approach can be implemented with great success. As part of a new project, the item pluspartner and specialist machinery expert has developed a punching system that reduces manual work steps to a minimum.

Strong foundations – partnership between item and ERWEMA

Since it was founded by two brothers in 2009, ERWEMA has established itself as an expert in specialist mechanical engineering. The family-run company offers complete solutions from a single source – from project planning and engineering through to the manufacture of individual components. At the same time, the company displays impressive flexibility. Whether for series production or customised requirements, it develops bespoke machines for just about any industry.

We have been working with item as a pluspartner for 13 years now.

The collaboration between ERWEMA and item goes back 13 years, and has intensified over time. The company has officially been part of the item pluspartner network since 2012. The network’s members make their expertise available to each other, working with other partners in the network to implement innovative projects and solve complex issues together. Right from the outset, ERWEMA has been using the economy variant of Line 8 from the item Building Kit System. Its latest project – automating sheet metal machining with a punching system – was no different.

What does automation look like in sheet metal machining?

In sheet metal machining, automation means using robots and automated systems to take care of work steps that have previously been carried out by hand. This includes the cutting, bending, joining (e.g. welding), deburring and handling of workpieces. The aim is to make processes more efficient and precise, while at the same time increasing output.

Another advantage of automation is that it enables the linking of consecutive work steps such as laser cutting followed by bending. Throughput times are reduced as a result, and the quality of the end products is higher. At the same time, automation helps counteract the effects of the skills shortage and boost cost-effectiveness – especially in the case of series production and medium-sized batches.

Spotlight on the automatic punching system

For the reasons mentioned above, ERWEMA developed an automated punching system for a customer that manufactures sun shading systems. Previously, staff had to check the production documentation, select the appropriate punch, and then finally set it up manually. The process was not only time-consuming, it was also prone to error. “The set cycle time is 30 seconds. In the past, this meant that all the manual steps had to be carried out within that time,” explains Alexander Erhardt, CEO and owner of ERWEMA GmbH.

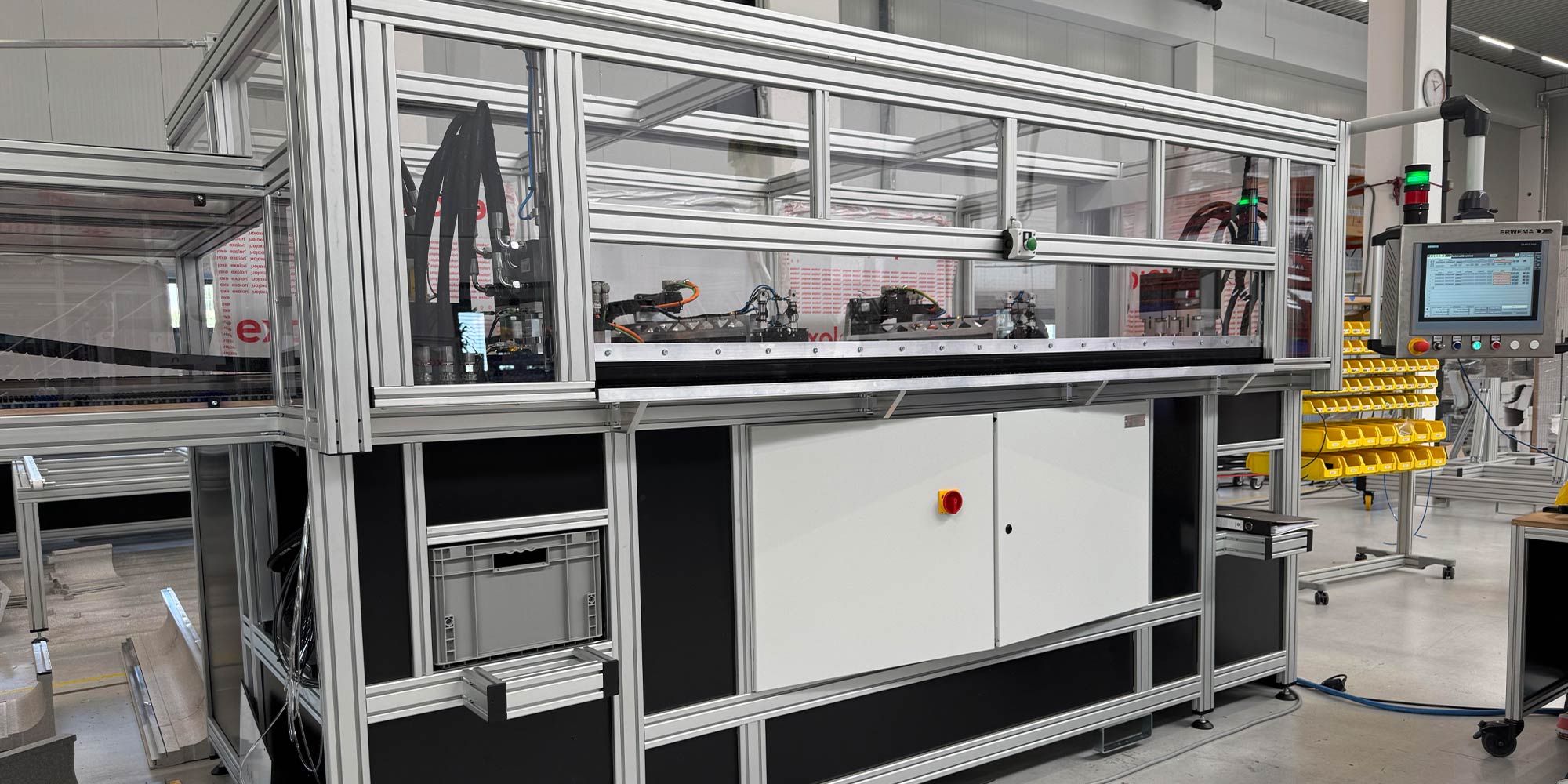

The automatic punching system has reduced manual processes to loading and removing the sheet metal.

The new system has changed everything. The only thing staff now have to do is load the sheet metal into the system and take it out again. The actual punching is fully automatic. One particularly innovative feature is Industry 4.0 connectivity. Production data is taken directly from the customer’s ERP system. This ensures precision throughout the production process and saves valuable time.

Technical highlights – what makes the punching system so special?

The special characteristics of the punching system for automating sheet metal machining include:

- Efficiency: Up to 1400 sheets of metal can be machined every day, with six punching operations per sheet.

- Speed: The processing time per sheet is just 15 to 17 seconds, which is significantly faster than the set cycle time of 30 seconds.

Originally intended for use with flat sheet metal, the punching system had to be adapted to new customer requirements during the ten months of the project. Besides processing flat sheets, the system also had to be able to machine L-shaped sheets. Working in close consultation with the customer, it was possible to both expand the system flexibly and integrate it seamlessly into the existing production line. “To do this, we needed highly dynamic axes and, of course, an operating concept that enables rapid, ergonomic loading,” says Erhardt. One other challenge was the small amount of space available on the production line.

At 5.5 metres wide and 2.5 metres high, the system was specifically designed to machine wide sheet metal efficiently. At the same time, it had to be designed in such a way that it could be constructed above an existing system to make the best possible use of the limited space. To meet these requirements, ERWEMA engineered a floating cantilever system that guides the sheet metal over the existing equipment. “This is a truly customised solution – and that is exactly what we do. We build machines that are perfectly tailored to the needs of our customers,” continues Erhardt.

High-quality materials + flexible design = customised solution

Customised solutions require not only technical know-how and flexibility, but also the correct materials. This is precisely where the company’s long-standing collaboration with item comes in. ERWEMA uses the economy variant of Line 8, which is designed to make optimum use of materials. “We absolutely love this profile. It enables us to develop incredibly robust machines that will work reliably for many years,” explains Erhardt.

We absolutely love the economy variant of Line 8. It enables us to develop incredibly robust machines that will work reliably for many years.

Another plus point is that ERWEMA keeps a large number of profiles in the sizes 40×40, 80×40 and 80×80 in stock. “If any modifications have to be made, we can implement them easily for our customers,” Erhardt emphasises. Thanks to the stock availability, constructions can be adapted rapidly, and various work steps can operate in parallel – a key factor when it comes to efficient project implementation. In the current project, a frame made of item profiles forms the basis. ERWEMA manufactured the punching tools and other production parts in house, creating the perfect combination of high-quality materials and technical know-how. By developing this automated punching system, ERWEMA has shown how automation can be implemented to perfection in sheet metal machining.

Do you want to keep up to date on the various ways that item products are being put to use? Then we have just what you’re looking for! Simply subscribe to the item blog by completing the box at the top right.