Get answers to your questions about linear axes and 2D gantries based on actual practical experience.

Solutions such as linear axes and 2D gantries are vitally important for automation, but they come in a wide variety of different designs. This blog post gives you a comprehensive overview and addresses the most important aspects – from definitions and areas of application through to time-saving online tools and sample solutions.

Linear axes and 2D gantries at a glance:

- Function: A linear axis is for one-dimensional motion along a single axis. A 2D (and 3D) gantry is an XY(Z) system for complex motion involving more than one dimension, e.g. for positioning, machining and handling tasks.

- Design and configuration: item MotionDesigner®, which is completely free to use, takes care of complex calculations and provides a finished solution comprising linear unit, motor and controller in seconds.

- Technology and trends: Demand for small, intricate linear axes is growing, with timing-belt and ball screw drives the most popular choices.

- Modularity: The flexible item Linear System enables customised combinations and modifications.

- Documentation and ordering: item MotionDesigner® automatically generates a complete parts list and full project documentation. You can also order your solution directly thanks to the item Online Shop.

What is a linear axis?

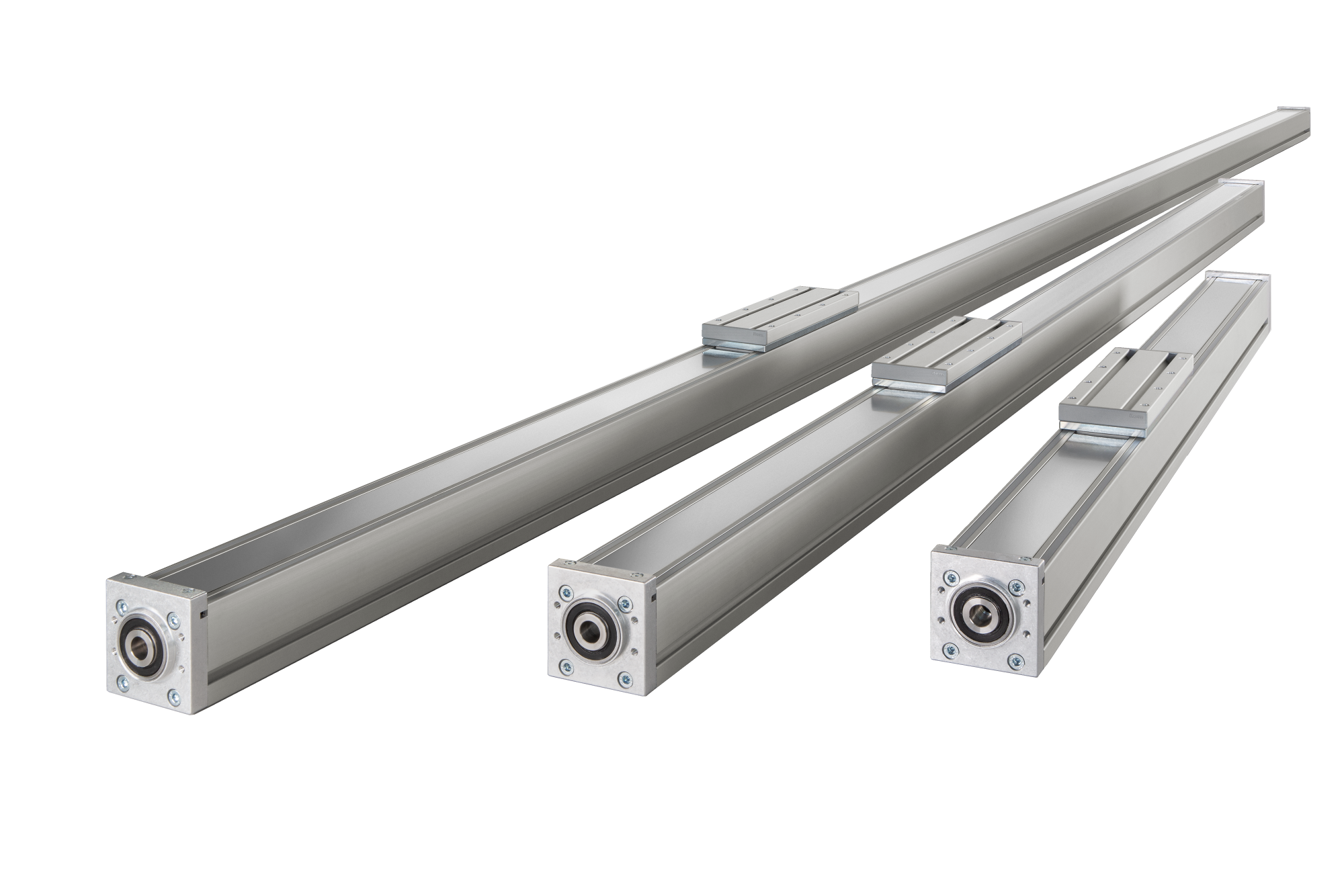

A linear axis (also called a linear module) is a mechanical system that is used for precise straight-line motion in industrial automation applications. It moves or positions tools and workpieces along a single axis.

Often driven by ball screw drives, timing-belt drives or linear motors, a linear axis converts rotational motion into linear motion. It normally consists of a guide profile and a moving carriage. A variety of drives can be selected for different requirements, depending on whether the focus is on speed, load or precision.

item linear technology at a glance

Discover our entire range of linear technology in the item Online Shop – ready-to-install linear units and linear guides, guide and drive components, motors, gearboxes and much more besides.

What are the areas of application for linear axes?

Generally speaking, linear axes are used wherever processes are automated – when manufacturing or handling components, for instance. Linear axes have an exceptionally wide range of applications.

Examples of applications for linear axes

The possible uses depend on the type of linear axis and can be explained based on a number of typical example applications:

- Lifting components

- Placing parts on a conveyor belt or removing them

- 3D printers: Moving the print head

- CNC machining: Moving a tool head over the workpiece

- Positioning sensors or camera systems

How do you select the right linear axis?

When selecting a linear axis, the most important considerations are as follows:

- Load: How heavy is the object you want to move?

- Dynamics: How quickly does it need to move and where is it going?

Aspects such as the necessary degree of precision and the ambient conditions (temperature, dirt accumulation, etc.) should also be taken into account. Based on this information, the acceleration forces are calculated. How powerful do the linear guide and linear drive need to be? And which combination of motor and gearbox is the right one?

You don’t need to do this complex design work yourself. We have developed item MotionDesigner® specifically for that purpose. This free online tool finds the perfect combination of linear unit, motor and controller in just a few seconds, based on the data you provide.

By way of an example, if you want to move a weight of 10 kg a distance of 3 metres within 5 seconds, item MotionDesigner® automatically calculates:

- What forces are acting on the linear axis

- Which guide is needed

- Which drive is required

One particularly practical feature is that the data you enter and the motion profiles you specify during the configuration process can be reused in the commissioning software – item MotionSoft®. What’s more, item MotionSoftStepper is available for stepper motors such as Integrated Motor ST NEMA24.

The process normally also factors in other parameters, as in this example:

- Environment: Is the axis located in a cleanroom, a steelworks or an explosion-protected area? Different requirements will apply depending on the surrounding environment.

Are linear axes suitable for modular expansion?

Yes, linear axes are suitable for modular expansion. Although this is difficult in most cases once they are installed, there are all kinds of options at the design stage. If you realise the load is higher than originally expected, for example, you can replace the original timing belt with a wider one.

The length of linear axes is scalable. At item, the length of a linear axis is built up in segments, which can be extended. Theoretically speaking, a rack axis can even have an unlimited length. In principle, you can keep on adding further segments. The motor of the rack drive is located on the carriage, meaning there is no limit on the length of the guide.

This is where designing the item Linear System as a modular linear technology building kit system really pays off. You can configure and combine the components you want to use in line with your specific requirements. As a result, you will find exactly the right linear axis for your task. If a large load is acting on a horizontal guide from above, for example, you will need a correspondingly strong linear guide, but high speed may not be an essential requirement. A small timing belt is then sufficient.

How do you configure a linear axis?

item MotionDesigner® costs nothing to use and is perfect for selecting and configuring a linear axis. A dialogue guides you step by step through the process of defining your transport task to arrive at a customised solution made up of the ideal components.

This online tool is very thorough. Working away in the background, it calculates each individual bearing in the linear unit based on the following questions:

- What can the bearing do?

- What is its inertia?

- What load scenarios are possible?

item MotionDesigner® runs thousands of calculations in a matter of seconds. These are far more precise than manual calculations. Besides obtaining the actual result, you can also ask more detailed questions:

- What torque does the motor need to have?

- What is the predicted service life?

How do you find the right linear axis for a precise positioning task?

item offers two efficient ways of finding the right linear axis for a precise positioning task:

- You can use item MotionDesigner® free of charge.

- You can check out the data sheets in the item Online Shop.

The data sheet values are always based on the worst-case scenario – in other words, the maximum loading and the maximum acceleration in an unfavourable environment. This ensures the linear axis delivers the promised precision from day one and also years later.

What new developments are emerging for linear axes?

Germany is seeing a clear market trend when it comes to linear axes. Demand is shifting away from traditional heavy engineering towards small, more intricate systems. This transformation is primarily being driven by high-precision sectors such as:

- Electronics manufacturing

- Chip production

- Medical technology

Timing-belt drives have come a long way, while ball screw drives are getting more accurate and becoming less expensive to manufacture. These two drive solutions are currently more or less equally popular and are taking over from older drive elements such as chain drives.

Online training: The basics of linear technology

Learn about the principles of linear technology and the different types of linear guides and drive technology in the free online course offered by the item Academy. All you need to access this content is an item user account.

Where can you order linear axes with a high level of precision?

You can order linear axes with a high level of precision from item. One key advantage of item MotionDesigner® is that this intuitive selection and configuration software automatically generates a parts list, complete with article numbers, and full project documentation.

As a result, you know exactly which item products are best suited to your transport task. Having been provided with a selection of the best options, you can make your decision and place your order directly in the item Online Shop.

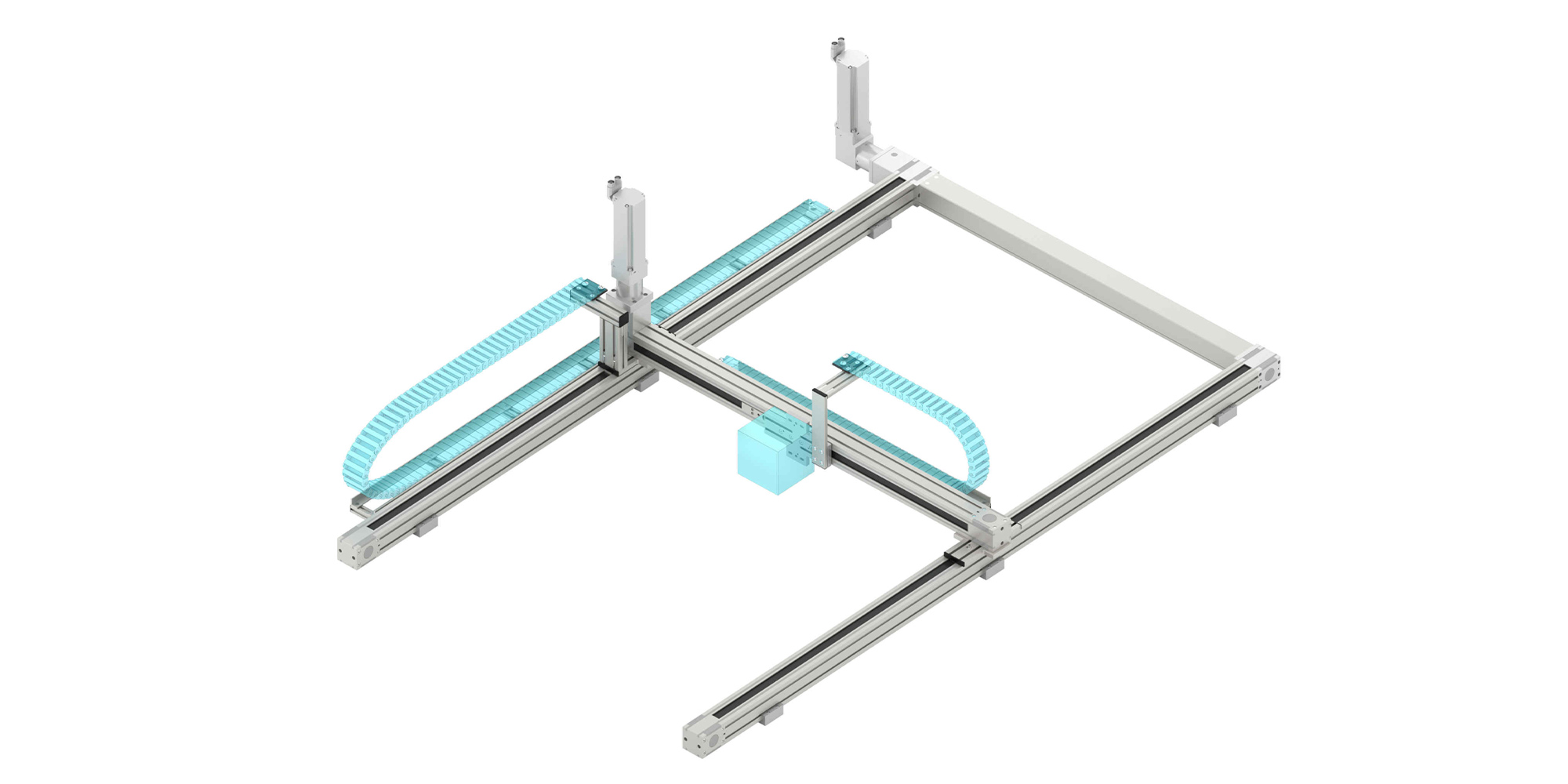

What is a 2D gantry?

A 2D gantry is an automated industrial handling system. It covers a large area and has the following tasks:

- Positioning workpieces with precision

- Machining workpieces (cutting, engraving, etc.)

Most 2D gantries take the form of a mobile bridge that runs on two parallel linear units and guides tools or grippers on more than one axis (X and Y).

How does a 2D gantry work?

A 2D gantry combines more than one linear axis to create a system. The name “2D gantry” is based on the fact that the system covers a large area in the X and Y directions and can make its way towards any point on this two-dimensional plane.

However, a third, vertical axis (Z axis) is often required for the actual task – lifting, gripping or machining a workpiece, for example. Besides 2D gantries, 3D gantries are therefore also often used in practice.

One important consideration when designing a 2D gantry is that one linear axis is often screwed onto another. The following aspects must therefore also be taken into account for the second axis:

- The weight of the first axis

- The forces generated when the first axis is moving in a straight line

You will find a range of preconfigured sample solutions for 2D gantries in the item Online Shop, each of which uses two synchronised linear axes (KLE 5, KLE 6 or KLE 8). It goes without saying that you can also configure your very own 2D gantry.

What are some typical areas of application for 2D gantries?

2D gantries are designed for applications that require precise and flexible motion in the X and Y directions over a large working area. They are highly versatile. Applications include automating measurement and test processes in areas such as quality control – for precise measuring and non-destructive testing with sensors. Another area of application is accurately labelling and marking components using laser and embossing technology, for example.

2D gantries are also ideal for materials handling – in other words, moving and positioning large workpieces such as panels made of wood, metal or plastic. They are equally suited to tasks such as laser cutting, engraving and milling. In logistics, 2D gantries are used to stack materials. In medical technology, they are helpful for precise positioning tasks in diagnostic or therapeutic applications.

Which 2D gantry is best for which application?

That depends on the specific application. Decisive aspects include the level of precision required and the load to be moved. You will find sample solutions for 2D gantries in the item Online Shop. In each case, two synchronised item linear axes are combined. The available options are KLE 5, KLE 6 and KLE 8. A larger size is generally recommended if you need to move a heavier weight. And thanks to the flexibility of the item Linear System, you can also configure your very own 2D gantry.

Can I order a 2D gantry as a complete set that includes a motor?

At item, you can order 2D gantries as a complete set that includes a motor. These are preconfigured sample solutions, each combining two synchronised linear axes selected from the options KLE 5, KLE 6 and KLE 8. The following are available for each option:

- 3D PDF

- CAD data

- 2D PDF, including parts list

- Product data sheet with all key technical features

The parts list provides an excellent basis and you can then, for example, swap out individual products for your particular project to adapt the standard solution to your specific requirements. Alternatively, you can use the same configuration as in a sample solution and order it directly.

FAQs about linear axes and 2D gantries

Do I need to be an expert to design a linear axis?

No, you don’t. item MotionDesigner® has been developed specifically to guide even non-experts reliably through the design process. A dialogue function leads you step by step to your solution. The software does the calculations for you and prevents typical design errors. If necessary, you can switch to expert mode to take a more detailed look at the design.

How do item MotionDesigner® and item MotionSoft® work together?

item MotionDesigner® is the online tool for designing hardware. It will find the perfect combination of linear unit, motor and controller. item MotionSoft® is the commissioning software and ensures seamless continuity. Details that have been worked out in item MotionDesigner® can be adopted directly, saving you a great deal of time.

What are the benefits of item sample solutions for 2D gantries?

The key benefits of item sample solutions for 2D gantries are saving time and ensuring process reliability. By providing you with a fully preconfigured and tested all-in-one package, they eliminate the relevant design and calculation work. Another possibility is to draw your inspiration from a sample solution and modify specific details.

When is a single linear axis sufficient and when is a system with more than one axis required?

A single linear axis is sufficient if motion is just required in one direction, in a straight line. Typical examples are simple infeed systems and moving components between two fixed points. A system with more than one axis is required whenever an application needs to move in more than one direction, whether two-dimensionally (XY gantry) or three-dimensionally (XYZ gantry). Such systems are perfect for coordinated processes such as pick-and-place tasks, for moving elements to several positions and for more complex processing routes.

Would you like to know more about linear technology? Simply subscribe to the item blog by completing the box at the top right.