Processes can be easily automated using our linear technology – thanks to 25 preassembled solutions.

Process automation is increasingly a necessity in modern production. By lowering unit costs and boosting quality standards, industrial development has done a great deal to raise efficiency levels. However, benefits such as these can only be fully utilised if machinery and plants are one hundred percent tailored to the relevant requirements. This is precisely where our linear technology can deliver its benefits in full, primarily because it is preconfigured, flexible and accompanied by two web-based selection aids.

The fundamentals of linear technology

When it comes to automation, linear technology is one of the most popular solutions in industry. It is robust, reliable and easy to implement. But why “linear”? The reason is fairly straightforward – because the movement in this type of system travels along an axis. The slide, which carries the object that needs to be moved, travels forward and/or back along the axis.

Linear units can also be combined, which means they can support two and three-dimensional positioning. This approach can be used to execute complex sequences at a comparatively low cost. A crucial element in any linear unit is the linear guide, which is responsible for determining the direction of the motion and comprises two parts – the guide (rail) and corresponding transport element (slide).

An overview of linear guides

The two key components in a linear unit are 1.) the linear guide and 2.) the drive technology. There are basically three types of linear guide:

Roller guides

This type of linear guide uses rollers that run along cylindrical shafts. The design of the rollers supports play-free travel and ensures they cannot jump out of their guide. Advantage: Roller guides offer a particularly high level of flexibility.

T-slot sliders

These systems feature a profiled slider that runs along a profiled rail. Due to this profiling, the slide cannot come out of the guide track. Advantage: T-slot sliders are ideal for applications that do not have to be completely free from play and are generally recommended when on a tight budget.

Recirculating ball bearing guides

The key feature of these systems is their ability to accommodate high loads in a small space. In the principle of multiple points of contact, the rolling elements are arranged so that they run along one line and are finally recirculated along another track. Advantage: This system features low friction and excellent load distribution.

Drive technologies in linear technology

Cutting-edge drive technologies are always geared toward specific tasks. They can either be very fast or exceptionally accurate. The overall performance of a linear unit is determined primarily by the choice of drive technology, which has a significant impact on the precision, speed, carrying capacity and costs of a linear solution. The following drive technologies are available:

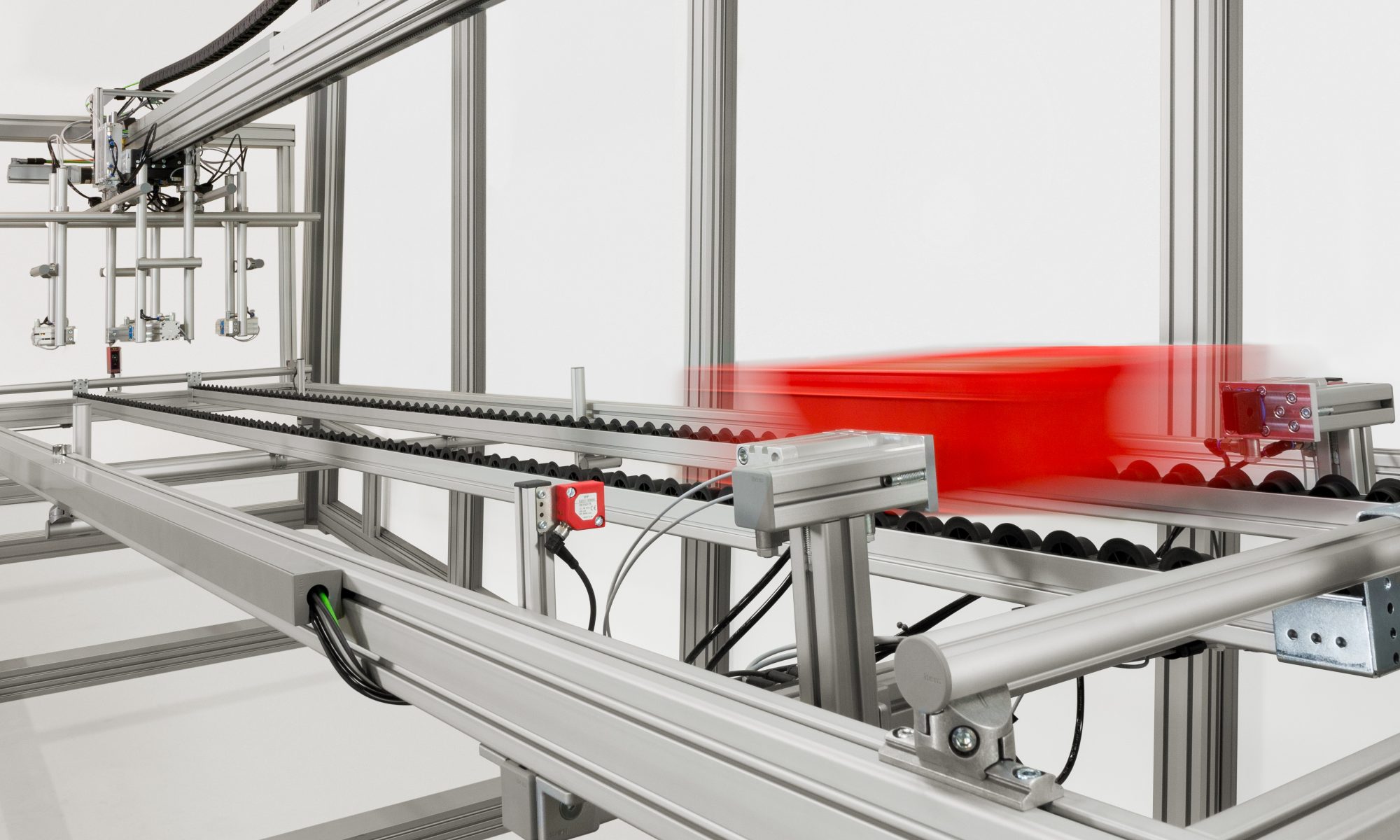

Timing-belt drive

This technology uses a toothed drive belt that locks mechanically around a toothed pulley that is driven by a motor. This mechanical interlocking eliminates slip and ensures that high forces can be transmitted. A timing belt comprises steel cables in a polyurethane sheath, has a long service life and supports a smooth running action. Advantage: This technology enables extremely dynamic movements and therefore short cycle times.

Ball Screw Unit

A Ball Screw Unit is based on a precision spindle. The speed and positioning accuracy of the system are largely determined by the lead on the thread. A non-turning drive nut that houses ball bearings is fitted to the spindle. These ball bearings circulate in the thread and ensure that the nut moves along a straight axis as the spindle turns. Because the ball bearings are very slightly larger than the track in which they run, they produce a pre-tensioning effect that eliminates play and supports load-carrying capacity. Advantage: Ball Screw Units are ideal when precise positioning and a lot of power are required.

Chain drive

Linear units with a chain drive transfer large forces in the direction of travel, but are limited in terms of positioning and travel speed due to their design. However, they exhibit excellent failure load, which means chain drives are often used for vertical applications. Advantage: Chain drives are resistant to problems caused by soiling, can transfer high forces and are also very suitable for vertical movements. This design is also particularly well suited to building conveyor systems with rollers, because the force in a chain drive can be converted into a rotary motion via sprocket wheels positioned anywhere on the linear unit.

Rack drive

The driven gearwheel in a rack drive interlocks with the straight rack to eliminate the possibility of slip. The rotary motion of the drive motor is thus converted directly into the rectilinear motion of the slide. This enables two applications: 1.) The load travels with the driven gearwheel. 2.) The drive is fixed in place and the load travels with the moving rack. Advantage: A rack drive is robust, can lift heavy loads safely and can position devices accurately even over long distances.

The advantages of our linear solutions

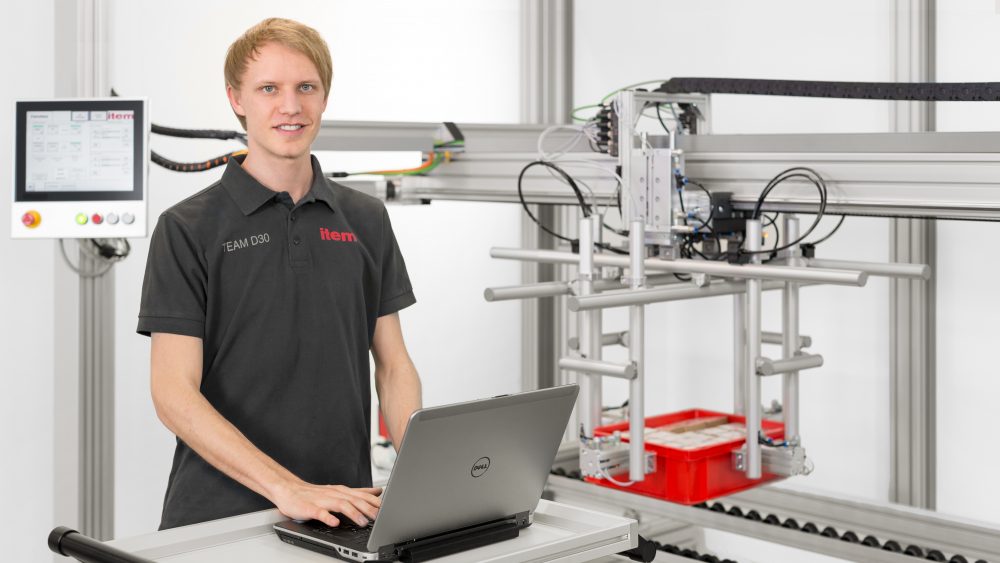

Since all projects come with their own specific requirements, they also require similarly specific linear solutions, which usually means engineers have to spend a considerable amount of time and money developing suitable technology. Not only do they have to identify the components that are called for, they also need to put them together to create a linear unit. Our Linear System takes care of all that for them – thanks to its 25 preconfigured Linear Units for a whole range of applications. What’s more, engineers can rest assured that the Linear Units satisfy all technical safety requirements and will fit together perfectly. These basic models for typical tasks are supplied with drive elements, slides and accessories and are therefore ready to be installed straight away.

Engineers who opt for one Line get the optimum technology for their process. Moreover, each Line includes a selection of Linear Units in different performance classes that can be selected according to very specific needs. As there are no limitations on the drive train, our Linear Units are also entirely flexible, and this flexibility – combined with time savings – can significantly cut costs. On top of all that, our linear technology is of course fully compatible with the MB Building Kit System and, if any questions should arise, we are on hand to help – around the world.