Eschewing chemicals and instead harnessing nature (with the aid of a little engineering), farmers can use parasitoid wasps to help protect their crops. The process of packaging these wasps’ eggs for pest control purposes has now been automated – thanks to robotics and laser technology.

Sustainability has a particularly long tradition in agriculture. Organic crop protection is one example. For decades, specialists in this field have been puzzling over questions such as how to protect crops in an effective yet gentle and natural way. Beneficial organisms are amongst the solutions. These natural “enemies” of pests are specifically used to eliminate them. The parasitoid wasp (Trichogramma brassicae) is one particularly effective beneficial organism. By laying their eggs in the eggs of other organisms, the females are able to eliminate the pests at the earliest possible stage. One way in which parasitoid wasps are valuable to farmers is controlling the European corn borer (Ostrinia nubilalis) – a moth whose larvae destroy around 4 percent of the world’s maize crop every year.

BIOCARE Gesellschaft für biologische Schutzmittel mbH, an SME based in the Lower Saxony town of Dassel, is a pioneer in organic crop protection, especially solutions involving parasitoid wasps. The current topicality of sustainable agriculture means demand for its products is growing, so BIOCARE has had to increase its production capacity. When it came to optimising the manufacture of special capsules to apply the parasitoid wasps, the company turned to ibk IngenieurConsult GmbH, a member of the item pluspartner network. The result was the creation of a two-part, automated capsule packaging system for these beneficial organisms. This blog post focuses on the first station. Profile technology from item was used in a variety of ways in both parts of the station.

An overview of robot applications

Read our white paper to discover specific applications and other advantages of robotics in industry – and explore why lightweight robotics is a particularly worthwhile investment for small and medium-sized enterprises.

GO TO THE DOWNLOAD

Sustainable crop protection – looking for an automation technology partner

BIOCARE initially thought a robot solution of this kind might be on too large a scale for an SME. “But I soon learned otherwise. It was an investment we could well afford, and the support on offer was on a whole different level to what I’m used to from machine manufacturers. Quite simply, the entire company is geared towards providing everything – from the concept all the way through to implementation,” says Sebastian Beitzen-Heineke. He and his sister Elisa Beitzen-Heineke jointly run the company established by his father in 1995. His description nicely sums up the broad-based approach of ibk IngenieurConsult GmbH.

We are increasingly looking to make our comprehensive automation technology know-how available to SMEs, too.

This item pluspartner specialises in planning, simulation and design work for factory equipment engineering and the construction of jigs and fixtures. Its core markets are the automotive, aircraft construction and specialist mechanical engineering industries. In 2011, ibk IndustrieService GmbH also opened, focusing on the production of jigs and fixtures, tooling, prototypes and small series. ibk grew up in the automotive sector, where it remains very active to this day. In recent years, the company has expanded its support for SMEs. “We are increasingly looking to make our comprehensive automation technology know-how available to SMEs, too, especially on a regional level,” explains Head of Technical Sales Michael Becker.

Pest control thanks to state-of-the-art technology and mother nature

Now to the product that is benefiting from the new system’s automated packaging. BIOCARE’s TRICHOSAFE® capsules are balls/spheres containing eggs of the Angoumois grain moth (Sitotroga cerealella) already parasitised by parasitoid wasps, along with host eggs that have not yet been parasitised. This results in a total of six hatching waves and thus to a duration of action of up to three weeks. Infestation of the European corn borer’s eggs takes place gradually. The paperboard packaging, which is made from pulp, serves two purposes – this material is completely biodegradable in the field and also protects the parasitoid wasps against adverse weather and egg predators. “Quite simply, the packaging provides excellent protection for the organisms prior to hatching, which results in a high yield,” explains Becker. In some parts of the world, host eggs parasitised by the parasitoid wasp are still spread by hand. Without protective measures, however, this leads to high losses. The family company’s solution clearly offers an advantage in this regard.

BIOCARE’s patented capsules to control the European corn borer can be applied by hand, by airborne robots (such as multicopters and drones) or using a capsule spreader.

BIOCARE’s patented capsules to control the European corn borer can be applied by hand, by airborne robots (such as multicopters and drones) or using a capsule spreader. TRICHOSAFE® cards can be used as an alternative or additional solution. As the result already suggests, top quality is a must when producing capsules for the beneficial organisms. The very first step is to make holes in paperboard sheets that each incorporate 200 hemispheres. Two of these sheets are subsequently bonded together to produce the capsules, which are filled with eggs and punched out. Previously, a needle board was used to pierce the holes in the hemispheres. However, this approach had a limited capacity and meant that the holes were prone to become ragged at the edges, which led to them getting blocked if it rained.

Automated packaging system for parasitoid wasps used in agriculture

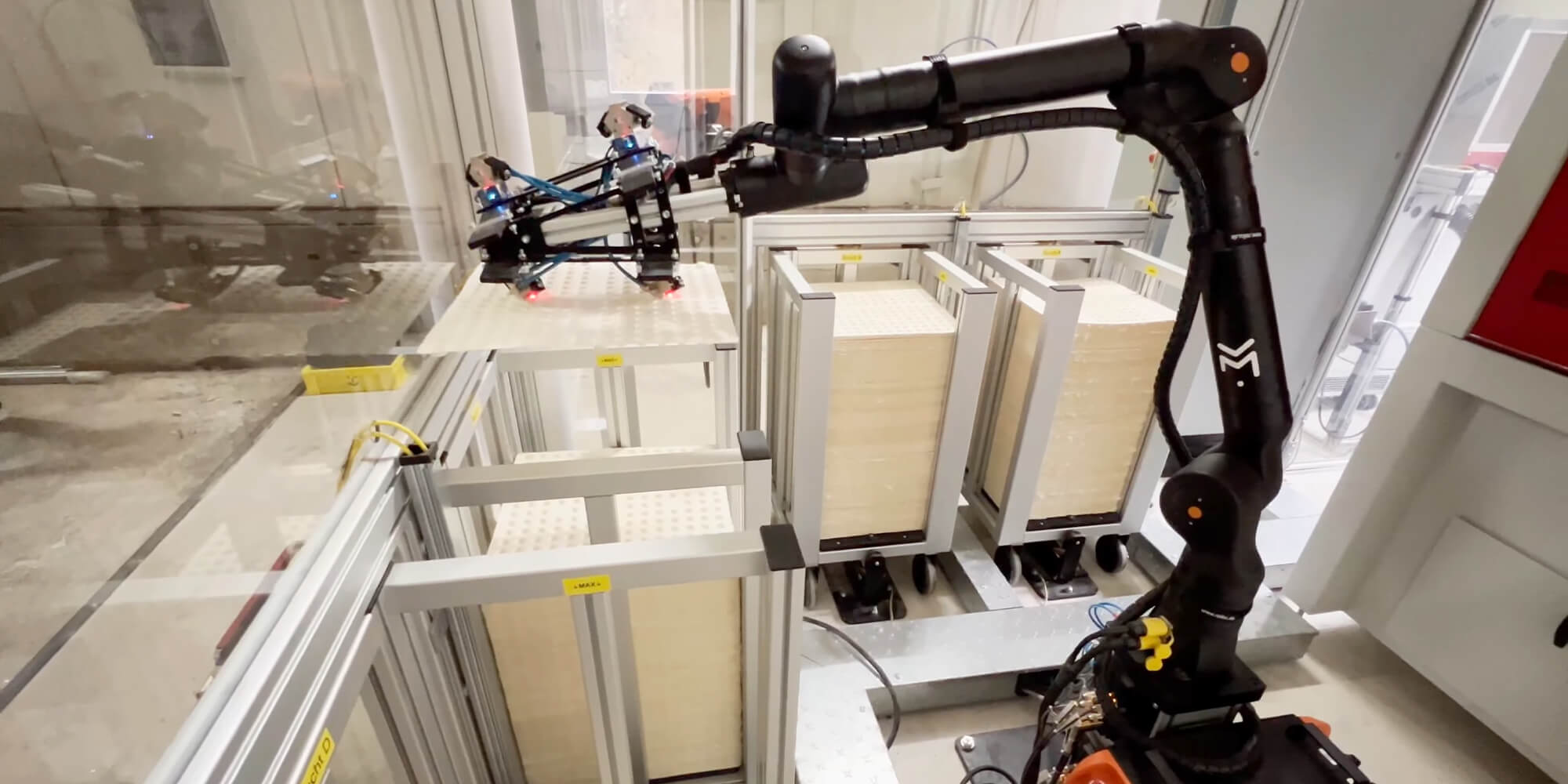

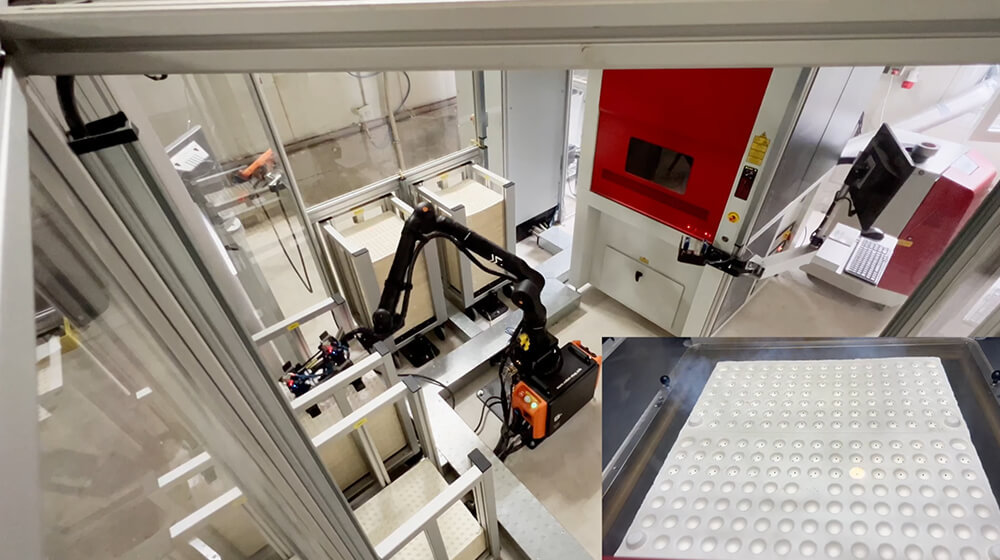

A trotec laser gmbh laser cell, which is located in the centre of the system, now assumes the task of creating these holes, and their size can be defined with flexibility and precision. The system’s frame and enclosure were built using item profile technology. A seven-axis cobot supplied by Kassow Robots is located in front of the cell. Materials are supplied using three trolleys based on item technology that approach the station from outside through access openings. A fourth, empty trolley is also ready and waiting. A process cycle starts with one of the three filled trolleys. The robot picks up an unprocessed sheet and takes this to the laser cell. “With its double gripper from Schmalz, the robot first picks up the sheet that has just been processed, rotates through 180 degrees and then puts down the sheet that doesn’t yet have any holes in it,” explains Becker.

In the packaging system’s second station, further processes will be automated – such as filling the hemispheres with the beneficial organisms’ eggs, joining together the paperboard sheets and, finally, punching out the capsules.

The robot then deposits the processed sheet on the next trolley and the process starts again from the beginning. In this way, all the sheets are gradually processed in around four hours. A wenglor sensoric group sensor detects the current pile height. Although a door made from item components has been integrated, this only needs to be used to carry out cleaning work or adjust the laser settings. Only at the start of the shift, the three trolleys need to be provided ready for use. “That leaves more time for more important work,” says Sebastian Beitzen-Heineke. In the packaging system’s second station, which is currently still in the process of being completed, further processes will subsequently be automated – such as filling the hemispheres with the beneficial organisms’ eggs, joining together the paperboard sheets and, finally, punching out the capsules.

Trusting partnership for organic farming

For around two decades now, ibk IngenieurConsult GmbH has known all about the benefits of item profile technology, in particular through its automotive customers. This project once again highlighted these advantages, including the lightweight material. The trolleys used to transport the paperboard sheets are extremely light, which makes them easy to handle and move. As Becker emphasises, the scope provided by the modular design was once again key: “Flexibility is a significant benefit of item. You can create any design you want. Even if you need something extra or the customer requests a modification, it’s easy to adapt the existing design rather than building something from scratch.”

The design of this system has saved me more work than ever before during the conceptual design of specialist machines.

The general willingness to experiment was a key factor. ibk has its very own innovation lab, where it was able to perform basic tests using dummy eggs produced by a 3D printer. The company used such experiments to put the system’s process reliability to the test. The acceptance of orders is also dependent on test runs of this kind. Their insistence on top quality and the fact that they are committed to delivering customer benefits make ibk IngenieurConsult GmbH and item Industrietechnik GmbH perfect partners. The conclusion reached by BIOCARE’s Managing Director says it all: “The design of this system has saved me more work than ever before during the conceptual design of specialist machines.”

Want all the latest updates on innovative robotics applications? Simply subscribe to the item blog by completing the box at the top right.