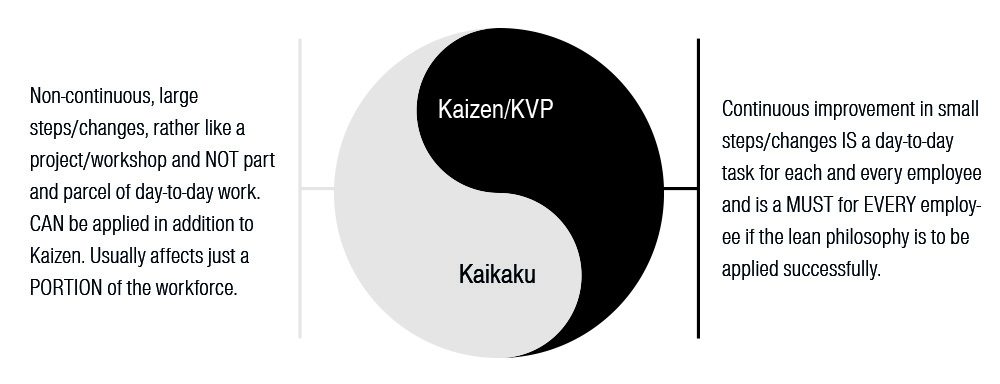

A comparison of two (seemingly) totally different lean principles.

We’re very experienced when it comes to the methods of lean production and have touched on them here many times before. However, in a world as rich and varied as that of lean production, it’s hardly surprising there are still some “undiscovered gems” on the “lean map” that are well worth a mention on the item blog. And that’s precisely what’s coming your way in this post, as we take a look at the lean concept of Kaikaku, which is frequently described as the opposite of Kaizen. Often mentioned in the context of lean management, the term Kaizen combines the Japanese words for “change” (Kai) and “for the better” (Zen). Basically, Kaizen describes the attitude of pursuing improvement. The key in Kaizen, however, is that this process of improvement never ends – and that possibly gives away how Kaikaku is different.

From Kaizen to the continuous improvement process (CIP)

Although the term Kaizen is used frequently with regard to the lean concept, it is necessary to draw a distinction. In Japanese culture, Kaizen has worked its way into numerous areas of life and discourse. When Kaizen is applied specifically in production, we talk about the continuous improvement process (CIP). It is important to stress that this is a measure implemented by the entire workforce. After all, it is the individual employees who work day in, day out at the Gemba, i.e. the “actual place” where value is created.

Although management are well advised to see the continuous improvement process in action with their own eyes during regular Gemba walks, the Kaizen philosophy cannot be enforced on a top-down basis. Instead, it has to be put into practice on a daily basis. This produces a positive fault culture that encourages everyone to examine what they are doing and get better all the time. The right tools and defined rules are crucial components for success.

Kaikaku vs. Kaizen/CIP?

As sensible as it is to pursue gradual improvements based on Kaizen or CIP, that isn’t always the perfect means of achieving the desired change in every single set of circumstances. However, the lean philosophy is rich and varied enough to offer alternatives. One of these is Kaikaku, a Japanese word that can be roughly translated as “radical change” or “reform”. That in itself highlights a contrast to Kaizen. Kaikaku is not about continuity or a never-ending process, it is about a precisely timed campaign that brings a new direction. For this reason, it is also sometimes referred to as “breakthrough Kaizen”.

Kaikaku and Kaizen/CIP are not rivals – quite the opposite, in fact.

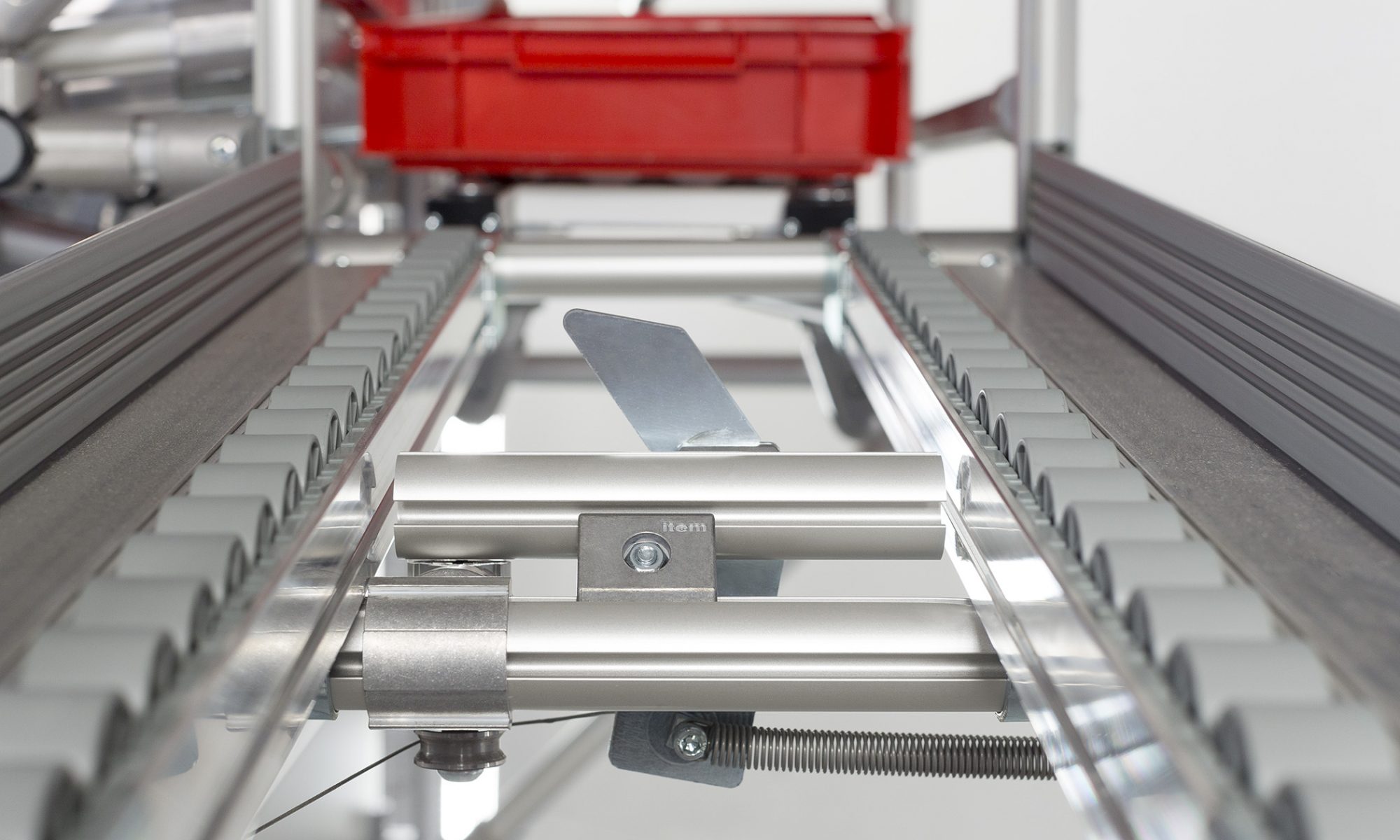

A typical example of Kaikaku in action would be an innovation project such as restructuring a production system. And, although this kind of project is implemented from the top down, that does not mean Kaikaku and Kaizen/CIP are “rivals” – quite the opposite, in fact. Kaikaku is often used to create a basis on which Kaizen, in the form of CIP, can be rolled out. One example would be the introduction of a U-line based on our Profile Tube System D30. Without a far-reaching change to the assembly process, it would not be possible to transform working methods. As a result, in this case, new methods are first rolled out as part of an organised process within a specific timeframe so that staff are then empowered to put into practice the philosophy of continuous improvement independently.

Are you interested in fascinating reports and innovations from the world of lean production? Then we have the perfect solution for you – simply subscribe to the item blog by completing the box at the top right!