Ergonomics isn’t just about looking after your back, it’s a discipline with a hugely varied range of objectives.

Having recently looked at a classic aspect of ergonomics, namely sitting, we thought we’d close our summary on ergonomics at industrial work benches by turning our attention to a number of aspects that, unfortunately, are often overlooked. The most important of these are modularity, the handling area and, last but not least, design. However, we’re also going to take another quick look at lighting, albeit from a different viewpoint.

Modularity and the zones of the handling area

In industry, no matter how carefully you plan a work bench, it will never really be finalised if it is being used properly. There are always going to be new needs that require flexible modifications. This is where a modular building kit system really pays off. For example, operators often find that they’ve got nowhere to put something down, but they can sort that out in no time by adding an extra shelf. What’s more, when using a building kit system, it’s just as easy to remove the shelf again later on.

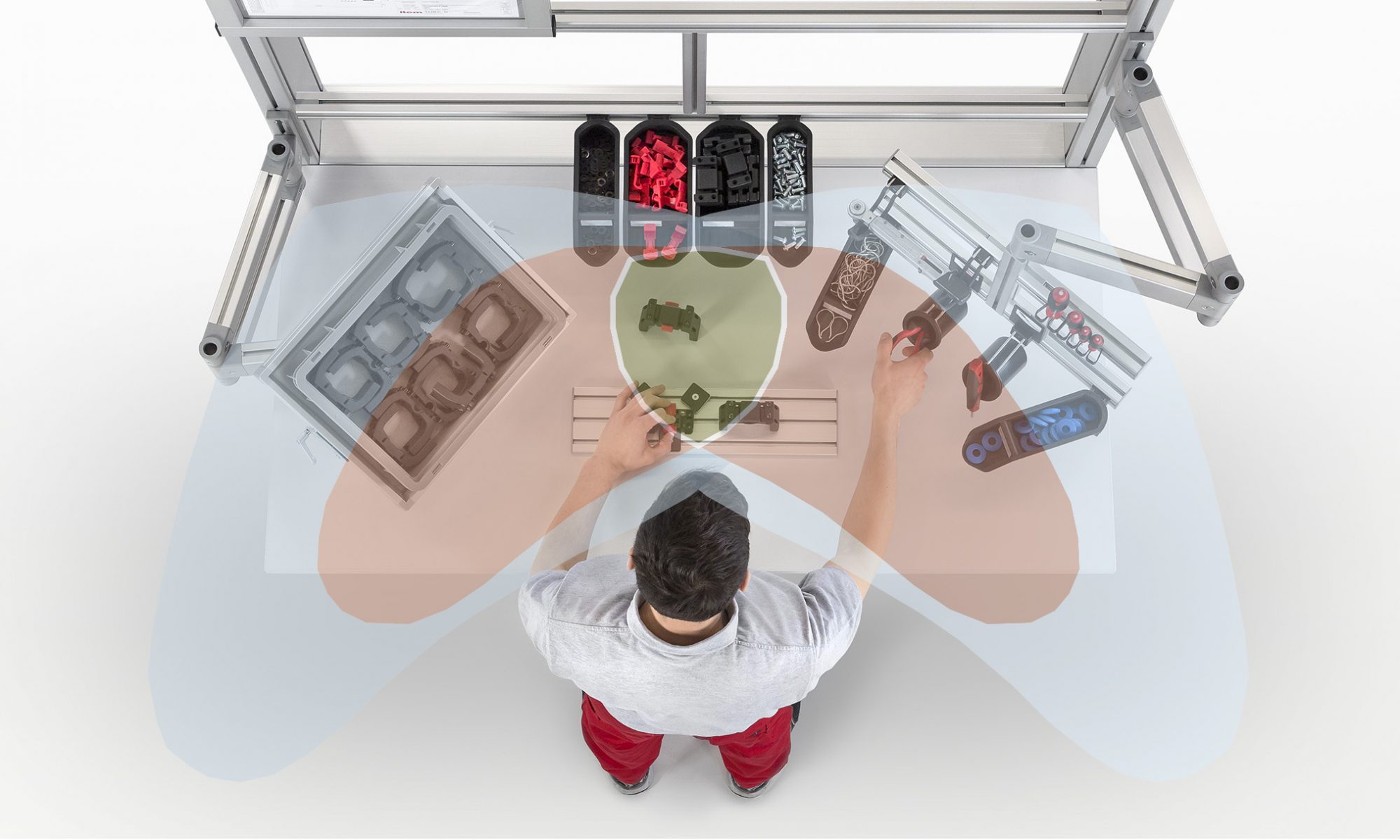

When designing an industrial work bench, it’s always important to take into account the handling area, too. Directly in front of the operator is the two-handed zone, where the process is actually carried out. The one-handed zone, meanwhile, is the best place to position materials and tools that are in frequent use, because workers can reach everything with ease, without having to turn their body. These handling area zones are different for everyone, so it’s important that every worker can arrange material supply and picking systems to suit their own specific needs. Pivot arms are an ideal option for positioning tools in the one-handed zone. They can be fitted with trays (such as Toolboards) as well as parts containers, hooks and holders for stowing tools where they can be easily accessed.

The role of lighting at the industrial work bench

Unlike lighting at an office workstation, where employees are normally all carrying out very similar tasks, the lighting at an industrial work bench has to be tailored precisely to the process that is being conducted there. It is particularly important that the lighting is directed at the working surface to ensure optimum effect. Less-than-optimum lighting conditions don’t just affect the concentration and performance of employees, they also force them to deviate from the ideal position as they try to get a better view, thereby taking all the risks that come with poor posture. This shows just how closely interlinked all the various aspects of ergonomics are.

You can find out more about lighting at the work bench in our special article on the subject.

Design also contributes to ergonomics

While we’re talking about how things look at the work bench, it’s worth pointing out that studies have shown workers rate chairs as more comfortable when they like the look of them. However, it is important to point out that this effect declines over time – the longer an employee is sitting in a chair, the more important its physical comfort becomes. Nonetheless, design has a tangible effect on how comfortable employees feel. Moreover, that doesn’t just apply to chairs, it is also true of the entire industrial work bench.

Employees working in an environment that they actively like are more motivated to keep the working surface clean and tidy. On top of that, structured visual design and functional design language make it much easier to grasp working processes. High-end design also offers companies an elegant means of projecting an image – both internally and to the outside world. One thing leads on to another. In fact, that is a very neat way to sum up the holistic approach that is intrinsic to ergonomics.