How a student project is showing the way forward for environmentally friendly weed control.

The use of herbicides in agriculture presents significant risks for humans and the environment. Residues are frequently found in the groundwater, with Switzerland being affected particularly badly by this type of pollution. In addition, a study commissioned by the “Bündnis für eine enkeltaugliche Landwirtschaft” (Association for Agriculture Fit for Our Grandchildren) and Munich Environmental Institute discovered that herbicides and their breakdown products are widely distributed through the air. Investigations at 165 German sites found evidence of these substances at approximately three-quarters of the places examined, which were located between less than 100 metres and more than 1000 metres from fields that had been sprayed with herbicides. At the same time, however, there are not yet any solutions that can keep pace with the effectiveness and cost-efficiency of herbicides. For this reason, a team of students from ETH Zurich and the University of Applied Sciences and Arts Northwestern Switzerland has developed a prototype of an autonomous weeding robot – Rowesys, which stands for “Robotic Weeding System”. This operates entirely without the use of herbicides, destroying weeds in a completely mechanical way. For the frame structure, the students relied on profiles from the item MB Building Kit System.

Gentle, non-toxic weed control

Rowesys was developed within the space of nine months as part of a focus project. The ten-strong team consists of six mechanical engineers, two electrical engineers and two industrial designers. These kinds of focus projects at the end of a bachelor’s degree programme always involve the students finding practical uses for what they have learned during their course, and take into account every phase of the product development process. Weighing in at 300 kg, the four-wheeled weeding robot is 2100 x 940 x 1200 mm and is used in a sugar beet field. This crop is particularly vulnerable to weeds, making its fields especially suited to demonstrating the capabilities of Rowesys. Although manual controls have to be used to navigate the weeding robot to the actual field, it is fully autonomous once there. “Rowesys has two cameras. The front camera enables it to identify rows of sugar beet and position itself accordingly. A second camera, which is aimed vertically at the ground, ensures it can recognise individual sugar beet plants and also weeds, and differentiate between the two,” explains Pascal Lieberherr, initiator of the project.

The small ploughs dip about two centimetres into the ground and separate the weeds from their roots, leaving the ripped-out plants on the surface to dry out.

Weeds are removed by four ploughshares located on a structure at the rear of the weeding robot. These small ploughs dip about two centimetres into the ground and separate the weeds from their roots, leaving the ripped-out plants on the surface to dry out. Getting rid of weeds from between the rows of sugar beet is relatively easy. In the rows themselves, the challenge is to remove the weeds without damaging the beet plants. The ploughshares are therefore opened or closed, depending on the information the second camera passes on to the system. As a result, the sugar beet plants are not touched by the ploughs. The weeding robot travels at 0.2 m/s while removing weeds. Its maximum speed is 1 m/s (3.6 km/h). Various noises and the colours of the LED lights on the Rowesys also make it possible to identify is current mode. The internal electronics are enclosed in a futuristic, minimalist aluminium hull.

Profile technology working for more sustainable agriculture

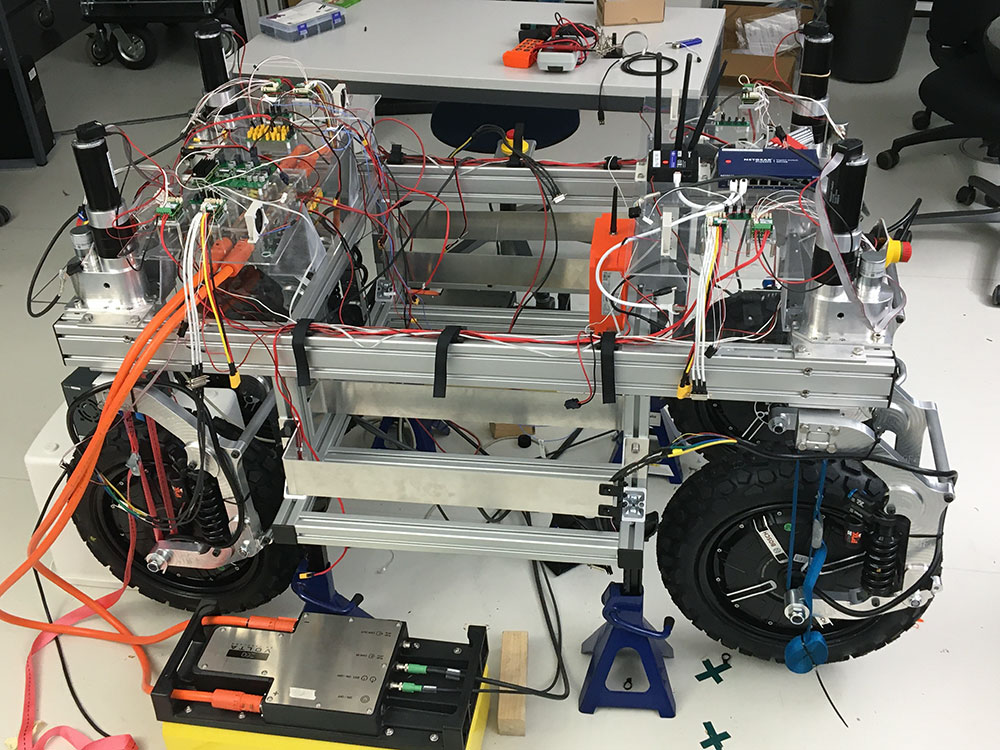

At the heart of the weeding robot is a kind of “skeleton” – a frame structure made up of aluminium profiles from item. The wheels, the complete electronics and the motors are attached to this. The profiles are also used in the ploughshare construction. To start with, the team looked at several different versions. This included considering a steel construction. “We were never completely happy with the idea of welding, however. These were our initial prototypes – exactly the stage where we need the highest possible level of flexibility. Steel simply doesn’t offer us that. Attaching additional fixtures is also very difficult and can involve a lot of effort,” Lieberherr says. However, that was when one of the ETH Zurich coaches for the project offered some vital input – recommending item profile technology. He highlighted the flexibility of the fasteners and the stability of the components from the MB Building Kit System.

The entire ordering, design and manufacturing process was much easier than it would otherwise have been thanks to the collaboration with item. Using the item Engineeringtool also saved us lots of time.

The positive experiences during CHIRON, another focus project that involved developing an innovative robot, also influenced the decision. The people involved in that project ultimately facilitated the contact with item Switzerland. “In addition to the support from item as a sponsor and the flexibility of the profiles, the advice we received was also very helpful. The entire ordering, design and manufacturing process was much easier than it would otherwise have been thanks to the collaboration with item. Using the item Engineeringtool also saved us lots of time,” says Lieberherr. Plans are in place for optimisations to the weeding robot, which is already making clear the direction sustainable agriculture can take using innovative technology. Sustainability is a top priority at ETH Zurich in many different ways. For example, each institute has to pay into a special fund for every kilometre flown by one of its staff. The people responsible for this fund turned to the students and asked for ideas for focus projects that would contribute to the United Nations’ Sustainable Development Goals. This was what got the ball rolling for the Rowesys project.

Do you want to keep up to date on the various ways that item products are being put to use? Then we have just what you’re looking for! Simply subscribe to the item blog by completing the box at the top right.