An innovative material for a green future – how Cradle to Cradle® is making profile technology even more resource-friendly.

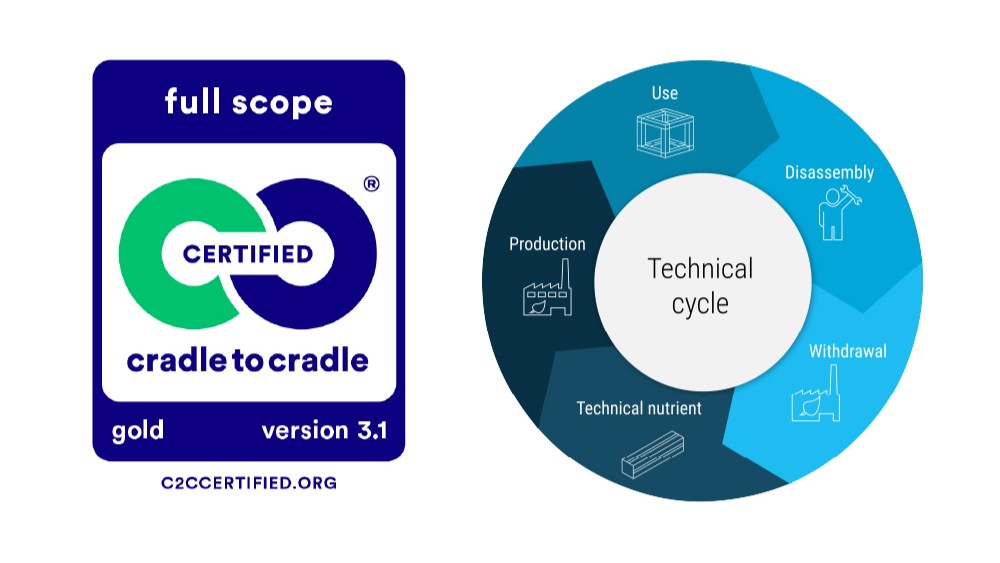

What if a product wasn’t just something that gets made on a one-off basis, but was instead part of an endless loop, or cycle? On reaching the end of its service life, it isn’t useless. Everything it’s made of is either biodegradable (biological cycle) or can be used as raw materials for new products (technical cycle). That’s the very idea behind Cradle to Cradle® (C2C) – a design concept that prevents waste and safeguards resources.

Cradle to Cradle® is the brainchild of German chemist Michael Braungart and American architect William McDonough, who was named “Hero of the Planet” by TIME magazine in 1999. Their innovative idea prevents resources from being wasted and instead creates products with a long lifespan that meet the highest environmental standards.

Our new, sustainable WFC profiles (WFC = wood fibre composite) are a prime example of this vision in practice. A vital role is played by the wood-based material used, which is made by NOVO-TECH GmbH & Co. KG. As Europe’s largest manufacturer of engineered wood products and a C2C pioneer, this German family-run business in Aschersleben is setting new standards in sustainability.

All the new products at a glance

Every innovation in one PDF! Discover all the new product developments and additional information in our New Products catalogue for 2025.

JETZT SICHERN

When sustainability meets functionality

There are plenty of lightweight fixtures and pieces of equipment in factories that don’t need the full strength of an aluminium profile. Profile WFC 8 40×40 and Profile WFC 8 80×40 are ideal solutions in such cases. Combining the tried-and-tested functionality of a standardised profile featuring Line 8 grooves with an innovative material, they satisfy the most stringent requirements for a circular economy. They are also fully compatible with the fastening elements and accessories in the item Building Kit System.

These sustainable profiles are made up of 75 percent wood fibres that are sourced as a waste product from the saw cutting industry (PEFC certified) and 25 percent recycled plastic, more specifically recycled polyethylene (PE). The PEFC label certifies that the timber comes exclusively from sustainably managed forests.

At the end of its useful life, the material is fully reprocessed and used to manufacture new profiles.

The wood-based material used, GCC HOLZart (GCC = German Compact Composite), is produced by NOVO-TECH. It has gained gold certification from the Cradle to Cradle Products Innovation Institute and has even achieved platinum certification in the “Material Health” category. At the end of its useful life, the material is fully reprocessed and used to manufacture new profiles. This keeps the carbon footprint of the profiles exceptionally low throughout their entire lifecycle.

Across Germany, we take back off-cuts and WFC profiles that are no longer needed. Feel free to get in touch with us to find out more about the return and recycling options.

Sustainable and efficient construction using WFC profiles

WFC profiles also offer further benefits. They are extremely easy to machine, weather resistant, electrically insulating and neutral to electromagnetic waves. You simply saw these lightweight profiles to length like wood. There is no need to deburr cut edges or tap threads separately. You can build lightweight equipment and fixtures such as racks, tables and partitions directly on site without needing any special tools.

Shaping the future – item and NOVO-TECH are committed to sustainability

item considers sustainability to be of the utmost relevance. One example of our green commitment is switching all the company’s sites in Germany to 100 percent certified green electricity. Our aluminium profiles are made up of 50 percent recycled material, and our KH profiles contain 70 percent wood fibres. The time has come to take our sustainable profile technology to the next level, and NOVO-TECH is the ideal partner for that. “We live and breathe sustainability right down to the tiniest little detail, and we feel a sense of responsibility to raise the profile of the cradle-to-cradle concept further still,” says Susann Krohn, Head of Management Systems with QA, Procurement and Development at NOVO-TECH.

Nothing is wasted during the production of German Compact Composite – 100 percent of the waste generated during processes such as texturing with brushes and planing is recycled.

The wood fibres utilised for GCC would otherwise be turned into pellets for wood burners or bedding for animals. When a used product such as bedding decomposes, it releases CO2, with one metric ton of wood generating around 1.5 to 1.8 metric tons of CO2. “We prevent this by using the wood chips in a product with a long lifespan, such as GCC – and also by taking back and recycling used WFC profiles. Our collaboration with item on this and in other areas is excellent,” explains Krohn. Nothing is wasted during the production of German Compact Composite, either – 100 percent of the waste generated during processes such as texturing with brushes and planing is recycled.

Want to keep up to date with everything that’s going on in the world of item? Simply subscribe to the item blog by completing the box at the top right.