Building with aluminium profiles offers numerous benefits, but there are times when it’s advisable to use a metal-free alternative.

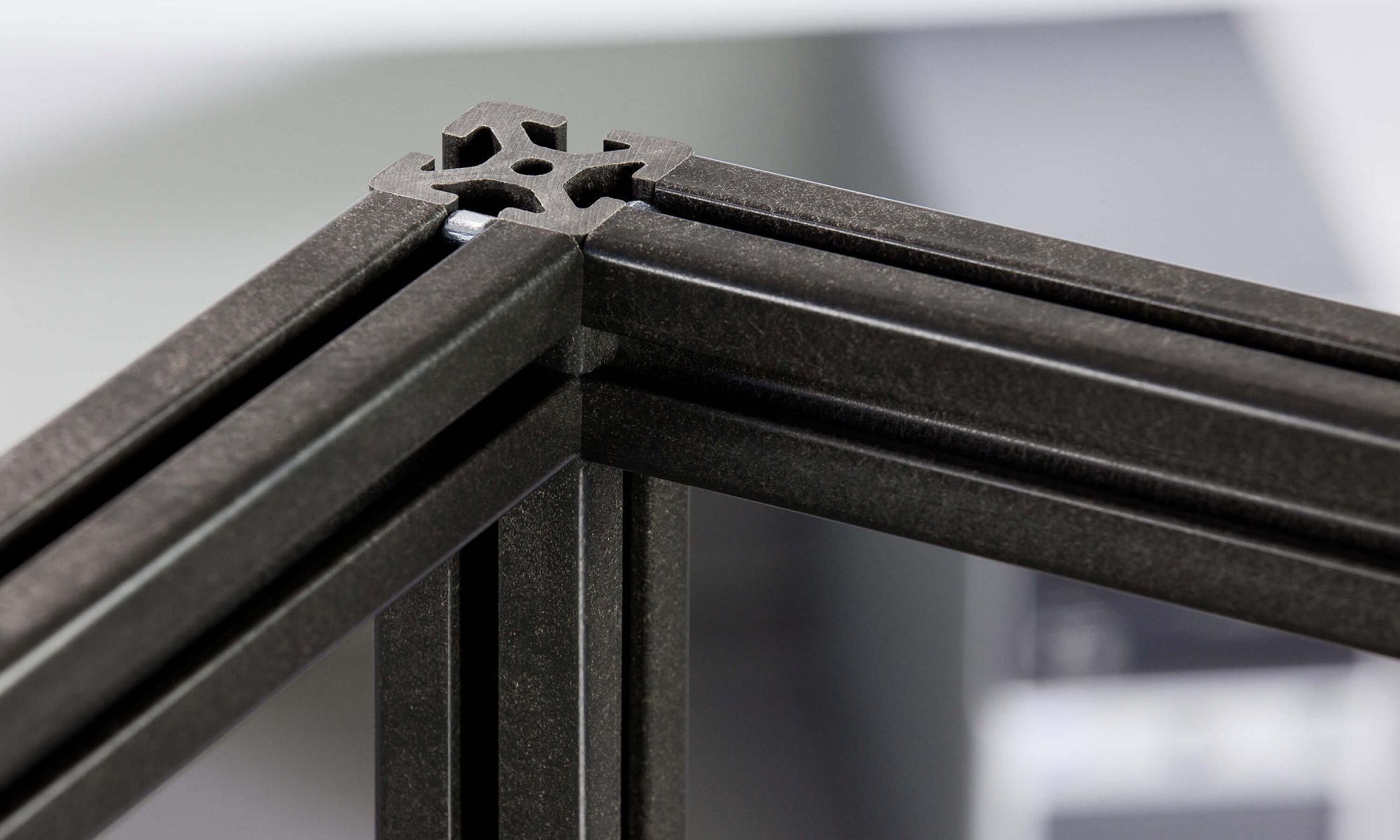

That’s why item developed Profile KH for the MB Building Kit System. This particular profile is based on a composite of thermoplastic (polypropylene) and wood from sustainably managed forests bearing the PEFC label. Comprising over 70 percent wood fibre, Profiles KH are lighter (1.06 kg/m) and more ergonomic than their aluminium counterparts. They also exhibit better CO2 values (CO2 equivalents: 3.6 kg) and are ideal when it comes to electrical insulation or transparency to electromagnetic waves. What’s more, they are fully compatible with the item product range. Just like their aluminium equivalents, Profiles KH feature a Line 8 profile groove, which makes it possible to use any item fastening elements and means panels can be built directly into the profile frame. The potential applications range from assembly trolleys, mobile racks and partitions to guards, screens and even laboratory equipment for EMC measurements. A KH variant is also available for the Lean Production Building Kit System.

Anything but your typical mechanical engineering profile

The “classic” aluminium profile, meanwhile, clearly has the competitive edge in other projects. So what are the key points when deciding between profiles made from wood-plastic composite and those made of aluminium? We decided to put the question to Marco Nieschwietz. As a product manager at item, he knows all about Profiles KH.

Are there situations where you would say Profiles KH are particularly suitable?

Whenever I know that the load will be manageable and predictable, there’s a good chance I can use Profiles KH. You can even work this out using the item Engineeringtool. Another example is when I have, say, mobile factory equipment that I need in production – such as a side carriage or a small table with castors to put various tools down on. In such cases, I can naturally switch to using Profiles KH because the load is low, and the resulting solution needs to be movable. And it’s easier for me to build such solutions using Profiles KH than with the aluminium version.

Apart from mobile solutions such as assembly trolleys, what other examples are there?

If a Profile KH and an aluminium profile are both at 20 degrees, the latter will always feel colder to the touch because it conducts heat more readily. Wherever my skin comes into contact with the structure, the Profile KH will be much more pleasant to handle. You could say it’s more ergonomic.

Thanks to various measures, including cladding frames and factory equipment with Profiles KH, the company managed to reduce the number of sick days.

One of our customers made an interesting discovery. In the logistics operations at their production facility, there were some frames and pieces of factory equipment made from aluminium and steel that staff in the working areas frequently touched. Bladder infections were becoming an increasing problem. To reduce the number of sick days taken as a result, the customer made several modifications that improved ergonomics for the workforce. This included using Profiles KH to clad points where there was frequent bodily contact – or switching these to Profiles KH entirely. Sure enough, after the modifications were implemented, there was a noticeable drop in sick days.

Another potential application is to build a guard element. Using a combination of Profile KH, Safety Hanger, Stand Foot Set and polycarbonate panels, you can create guard applications in accordance with DIN EN ISO 14120:2016 for up to 330 joules. In practice, this makes it possible to achieve field sizes with a width of 1500 mm. Depending on the type of production, several metres of guards could be involved. Profile KH thus offers a genuine alternative to aluminium guards that is cost-effective, more carbon-neutral and helps save resources.

The benefits of aluminium profiles & how they combine with Profiles KH

So when is it better to opt for profiles made of aluminium?

Whenever an application is subject to high loads, you should generally opt for aluminium. Other than that, you should look at what type of load you’re dealing with. Depending on whether it’s a high, static or dynamic load, aluminium profiles might more suitable than those made from a wood-plastic composite. It’s relatively easy to determine whether a construction using Profiles KH can support static loads (due, for instance, to an overlying mass) in the long run.

Aluminium can cope with dynamic loads extremely well.

It’s a different situation if, in addition to the load, there is movement involved due to an installed robot arm or linear unit, for example, or because the heavily laden construction is moved across uneven ground. Here, you’re looking at dynamic loads, in which case you’d go for aluminium because it can cope better than a material made from wood and plastic.

In what way do aluminium profiles and those made from a wood-plastic composite complement each other?

If I’m combining the two, I’m either doing so to save weight or because I know that people will come into contact with the material. I’ll then look into where there’s a risk of people bumping into the construction, for example, or where a profile has to be touched in order to move it. In these situations, I can add an upright made from Profiles KH. And wherever I know I need stability, I’ll opt for aluminium. Combination using the Line 8 groove presents a real advantage, as it ensures that aluminium profiles and Profiles KH are mutually compatible.

You can easily integrate a Profile KH into an aluminium profile structure to create an insulating effect.

One aspect that customers repeatedly mention is the insulating properties. Since aluminium conducts electricity, it can make sense to build certain areas using Profiles KH to prevent exactly that. After all, staff may well work with high voltages on specific structures or machines. In this case, I can integrate the insulation into the frame or structure because Profile KH provides insulation. This is a typical reason why profiles made from a wood-plastic composite are used in combination with those made from aluminium.

Sustainability as a key factor for mechanical engineering profiles

Let’s move on to sustainability, which is becoming an increasingly important aspect. How high is the primary energy consumption for Profiles KH?

We have detailed data from our manufacturer and suppliers. It’s always important to ensure you compare like for like. The primary energy consumption accounts for around a quarter of what it takes to press out an aluminium profile. You have to bear in mind, however, that the comparison is based on production from a new raw material. Both wood-plastic composites and aluminium can be recycled and remolded to create new profiles. Yet this comparison assumes that I’m sourcing the raw material afresh, i.e. from the environment rather than from existing components.

When it comes to sustainability, one advantage of Profile KH has to be that it is made of 70 percent renewable raw material.

When it comes to sustainability, one advantage of Profile KH has to be that it is made of 70 percent renewable raw material. But let’s not forget about aluminium. Although a finite raw material, it is in plentiful supply

What’s the situation with recycling? Wood is easy enough to recycle. Profiles KH, however, are made from a mix of wood and plastic. Is it possible to recycle such profiles fully?

Theoretically yes, but it’s not as easy as with aluminium, of course. We all know that aluminium profiles are in circulation across the globe, and aluminium is a very popular material for building machinery and specialist equipment. This creates a network in which I have plenty of opportunities to bring the material back into the recycling loop. I therefore know that it will re-emerge as a new aluminium product. In other words, it’s a material that can be used time and again.

Aluminium is a material that will eventually re-emerge as a new aluminium product.

Profiles made from a mix of wood and plastic, in contrast, are still a niche product. As things currently stand, they are recycled more by way of combustion to recuperate energy – that is to say, as normal household waste.

Interested in applications and solutions from item? Then we have something that’s right up your street! Simply subscribe to the item blog by completing the box at the top right.