By 2025, Senegal is aiming to reduce its CO2 emissions by 37 percent compared to its 2018 figure – and solar energy, in particular, will play a vital role in this.

The conditions for extensive use of photovoltaic systems couldn’t be better in Senegal, West Africa. In terms of sunshine, there are only minor fluctuations. The sun is high in the sky during the day, while the morning and evening twilights are both of short duration. Light falls at a steep angle, which means that even horizontally aligned photovoltaic cells achieve high levels of efficiency there. However, there is one thing that poses a threat to the success of solar energy as part of the energy mix in Senegal – dust from the Sahara. Mineral dust particles are carried into Senegal by the northeasterly trade wind. Each year, around 200 grams of dust land on every square metre, reducing the power output of solar parks by more than 20 percent.

Up until now, methods for cleaning the solar panels have proved either extremely arduous or unsustainable, which is why a team of students at Hamburg University of Applied Sciences (HAW Hamburg) developed an innovative system for cleaning solar panels as their bachelor’s project. The name of this system is “SeneSet,” which is made up of the first four letters of the country’s name, followed by the word “set,” which means “clean” in Wolof, the most commonly spoken language in Senegal. The team is being supervised by Prof. Anna K. Usbeck, professor of mechanical engineering and CAD in the Department of Mechanical Engineering and Production Management (IKP) at Hamburg University of Applied Sciences. The students are using the item Building Kit System to construct their prototype. This system offers the key benefits of end-to-end modularity and lightweight profile technology.

Creating a cleaning solution that saves both time and resources

For some years now, Prof. Usbeck has been concentrating on sustainable energy generation in Senegal, with a particular focus on photovoltaics. From an early stage in her work, one thing was very clear to her: “When it comes to cleaning the solar panels, new, customised technology is needed. It needs to be affordable, maintainable and suited to the specific conditions.” Up until now, either manual cleaning equipment with poles that are metres long or diesel tractors with water and brushes have been used. However, these systems are either arduous to use or unsustainable. By contrast, the new cleaning solution developed by the students in Hamburg is efficient and saves resources. The German Academic Exchange Service (DAAD) is supporting the innovative project with funding of around 50,000 euros.

The SeneSet frame, which is six metres long and around one and a half metres wide, is made from item profiles.

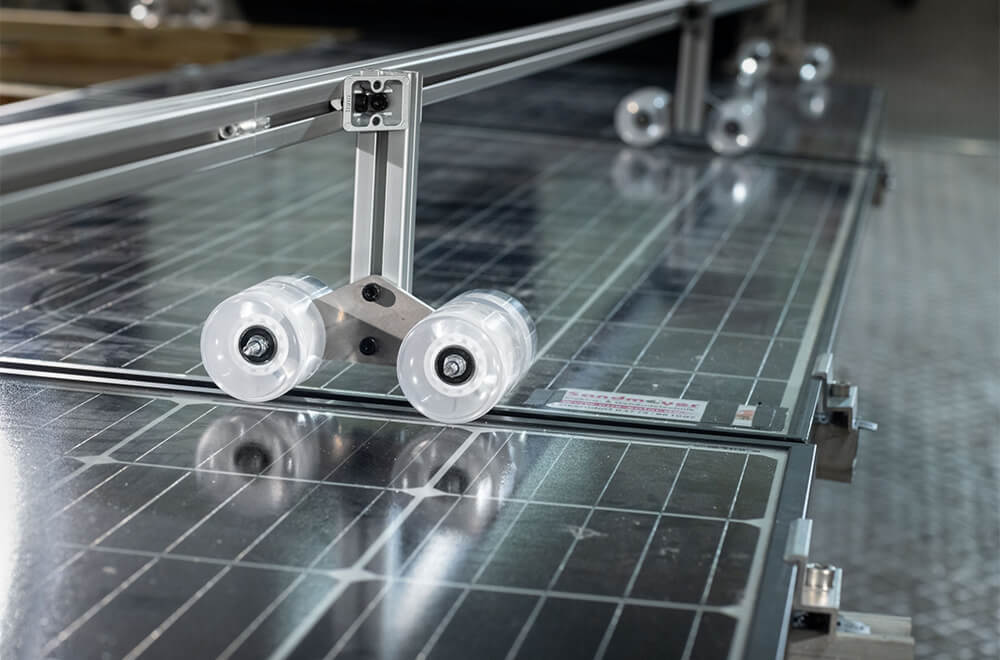

The SeneSet frame, which is six metres long and around one and a half metres wide, is made from item profiles. Eight small running gears with castors support the device. It can be transported on its castors from one solar panel to the next. A robotic solution was impossible for various reasons. For example, non-guided cleaning robots need to navigate independently on the relevant surface, so they need extra sensor technology. However, this technology can often fail due to dust and corrosion. It would also require a more complex control system. What’s more, an autonomous robot would need to move around on the panels, which is a very complex process and often slower, too, depending on the angle involved. Last but not least, SeneSet is to be produced in Senegal. “We therefore want to keep the components that cannot be procured locally and installed by the engineers there to an absolute minimum,” Prof. Usbeck explains.

Calculation reveals potential – 20 hours of work instead of 174

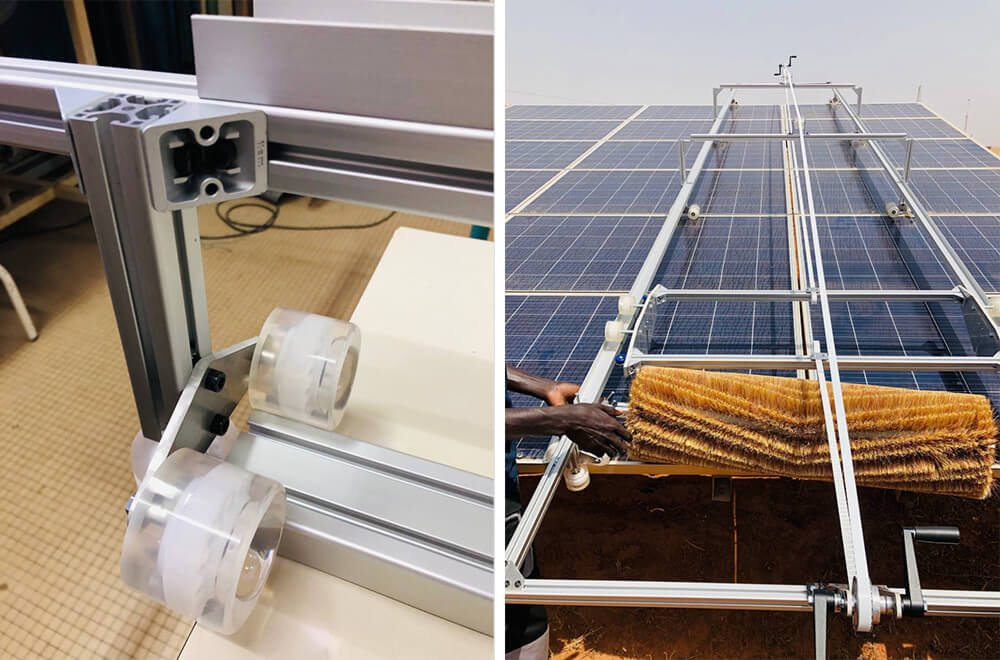

Thanks to a crank drive, one part of the system with a rotating roller moves at a right angle to the direction of travel, i.e. in the longitudinal direction of the frame. As it does, a brush removes the dust. To switch from one row of solar panels to the next, the system is lifted up and repositioned. It can be driven manually or, alternatively, with a high-powered cordless screwdriver. The team is still working on optimisation measures to ensure the screwdriver can continue working for periods that are as long as possible. Work to determine the best type of brush is also still ongoing. Wet and dry cleaning variants with different brushes and rubber and textile strips are to be tried out on a test stand in the near future. With this concept, the cleaning module can be swapped over, so it will be possible to use different variants in the future. However, the calculations already speak for themselves. Conventional manual cleaning of the 6960 solar panels in the solar park in Diamniadio, for example, takes 174 working hours. With SeneSet, it would take only 20 hours.

Practical test in Senegal using profile technology from Solingen

“At Hamburg University of Applied Sciences, we often work with item profiles, because they are lightweight and come in the lengths we need. They’re ideal for advance engineering purposes and for building prototypes. There are always changes to be made at these stages, and the fasteners mean we can adjust everything really easily,” says Prof. Usbeck. She also highlights two further benefits of the item profile technology – its rigidity and lightweight construction. In the first instance, 30 x 30 mm profiles were used. However, it transpired that the frame suffered from slight deflection due to its considerable length of six metres. The design was therefore adjusted accordingly. There is now also another variant in the pipeline, with dimensions of 60 x 30 mm, to prevent this effect. This variant is also to be fitted with item castors instead of the skateboard wheels that have previously been used. In February 2023, SeneSet and two of the students involved in the bachelor’s project traveled to Senegal. The solar panel cleaning system was dismantled and packed into a container for the flight. The first practical test was carried out in the two-megawatt solar park in Diamniadio, which is around 30 kilometres to the east of Dakar as the crow flies. There is close contact between Hamburg University of Applied Sciences and the Ecole Supérieure Polytechnique de Dakar (ESP in Dakar), which is not far from Diamniadio. “We still need to optimise a few things, but SeneSet certainly works,” says Prof. Usbeck as she comments on the outcome of the tests.

The students from Senegal are very impressed by item as a supplier and they incorporated the profiles into their structure straight away. It really is true that the language of technology is global.

Soon after the trip to Senegal, lecturers and master’s students from ESP paid a return visit to Hamburg, where they stayed for two months. The young visitors also started developing a prototype. This was the first time they had come across item profiles, as Prof. Usbeck explains: “The students from Senegal are very impressed by item as a supplier and they incorporated the profiles into their structure straight away. It really is true that the language of technology is global.” The students opted for 40 x 40 mm profiles, which have the advantage of being more rigid than the 30 x 30 mm profiles. What’s more, they have wider grooves, so the item rack profile can also be inserted. This is important because the cleaning system being developed by the Senegalese students is not to be driven with a timing belt but instead by a motor via a sprocket on the cleaning carriage. When designing their frame, the students made direct use of the free item Engineeringtool. In total, there are now three different and rival variants of the cleaning system based on item products. An in-house competition will be held to decide on the winning team. At the end of the process, there will ideally be a market-ready solution that, with a start-up behind it, will strongly support the energy transition in Senegal.

Mutual support and a joint approach to managing the energy transition

SeneSet is not the only collaborative project between Hamburg University of Applied Sciences and ESP in Dakar. “Cooperation to Focus on Renewable Energy Education (CO2FREE)” is also being funded by the German Academic Exchange Service (DAAD). The current focus is on developing a curriculum for a bachelor’s degree in renewable energies at ESP in Dakar. “We want the curriculum to closely reflect the requirements of the industry. We’re looking at questions such as what the curriculum needs to cover to ensure that graduates can successfully apply for jobs with companies in the solar industry or the hydrogen technology sector. There are a lot of changes in these areas,” says Imke Rieken, project manager of CO2FREE at Hamburg University of Applied Sciences. The challenges faced by the two countries are totally different. While the average age of the population in Senegal is around 18 years, Germany is grappling with a skills shortage. At the same time, further work to develop the Senegalese university landscape is needed. There is therefore a great deal of potential for mutual support. “We can only drive the energy transition forward by working together. We need the next generation to be global to achieve a shared future world,” says Prof. Usbeck with emphasis.

Do you want to keep up to date on the various ways that item products are being put to use? Then we have just what you’re looking for! Simply subscribe to the item blog by completing the box at the top right.