The JUICE space probe is currently searching for signs of extra-terrestrial life. When it came to designing a test structure for the space probe’s boom, Airbus used the item Stairway/Platform System.

Airbus isn’t just one of the world’s leading manufacturers of commercial aircraft. Airbus Defence and Space also plays a pioneering role when it comes to the production of space technology in Europe. Besides Earth observation and telecommunication satellites, this division of Airbus also develops, builds and tests probes for deep space exploration. The JUICE (Jupiter Icy Moons Explorer) space probe is to spend close to four years studying the Jovian system, using its measuring tools and sensors to establish whether possible habitats exist there. Airbus has spent the past few years developing and building this probe for the European Space Agency (ESA). On 14 April 2023, the big day arrived and the Jupiter probe, weighing 6.2 metric tons, was launched into space on board an Ariane-5 rocket from the Kourou Spaceport in French Guiana. However, before JUICE could be launched on its journey of exploration, it had to be put through various tests at the Airbus Satellite Integration Centres in Friedrichshafen and Toulouse. Using its Stairway/Platform System as a basis, item designed a solution for Airbus that fulfilled two key functions – it provided a working platform and also served as a substructure for an approximately 10-metre-long magnometer boom (MAGBOOM).

Space mission to investigate vital questions

Could three of Jupiter’s moons – Ganymede, Europa and Callisto – support life? Are there really extra-terrestrial beings to be found there? The aim of the JUICE probe mission is to provide answers to these fascinating questions. Airbus has a great deal of experience of deep space exploration. For example, it built the BepiColombo satellite for exploring Mercury and the Rosetta space probe with its Philae lander. As the principal contractor for JUICE, the French company heads up a consortium of over 60 European businesses. More than 150 employees at various sites were involved in designing and building the JUICE space probe. The focus of the mission is an investigation of the oceans that are hidden beneath the icy surfaces of Jupiter’s moons. Magnetic sensor systems can be used to investigate the internal structure of these celestial bodies in greater detail.

Final crucial tests before the space launch

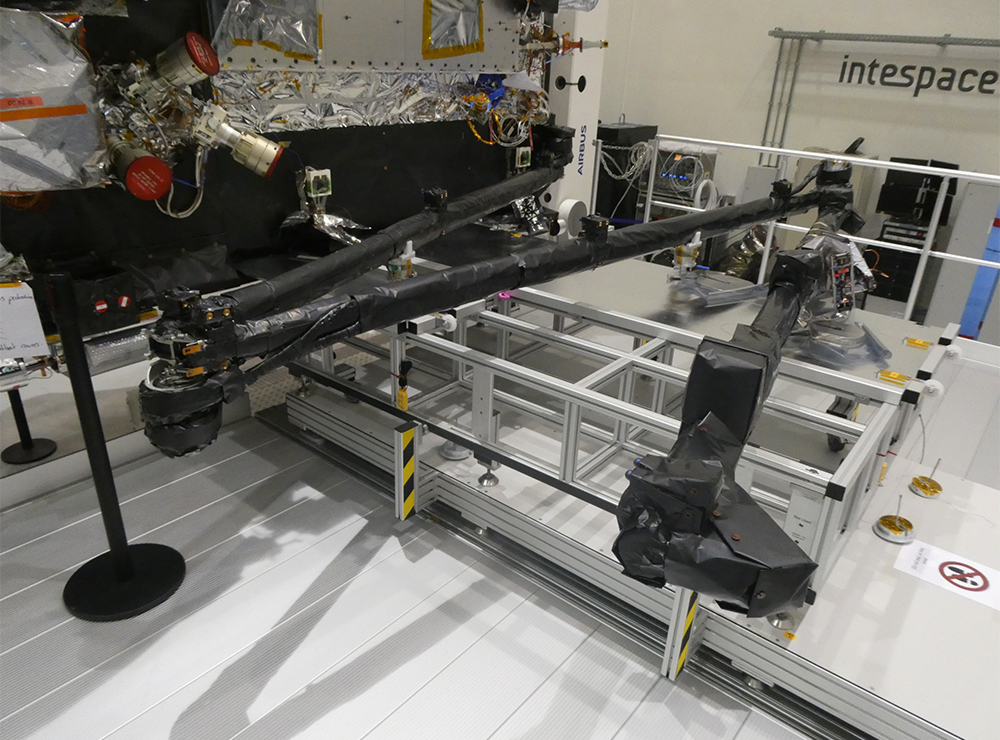

For the reasons outlined, the magnetometer boom (MAGBOOM) is a vital component of the space probe. It has five magnetically sensitive measuring instruments attached to it, weighs around 50 kg in total, is made from non-magnetic materials and can be folded out (deployed) to a length of up to 10.6 m. These various features ensure that the JUICE space probe itself cannot influence the measurements taken. In August 2021, JUICE needed to be put through its paces, and this process involved its final assembly and last tests. JUICE was therefore transported to the Airbus Satellite Integration Centre in Toulouse.

A special substructure was required so that the boom could be deployed on Earth for test purposes. This structure supported the boom while it was being deployed to ensure that no damage or buckling could occur.

The tests were to be carried out on both the probe and the intricately designed boom. To carry out installation work and testing on the extremely sensitive boom, the Airbus staff involved in the project needed a very specific structure. After all, the fold-out boom was designed to be as lightweight as possible and was dimensioned for an environment that is not influenced by Earth’s gravity. A special substructure was required so that it could be deployed on Earth for test purposes. This structure supported the boom while it was being deployed to ensure that no damage or buckling could occur.

Special test set-up from item comprising more than 4000 individual components

This is where item came in and became part of the story of this European space mission. Working in close collaboration with Airbus, a customised solution was designed, using components from the item Stairway/Platform System. This structure provided the boom with exactly the support it needed, meaning the MAGBOOM could be partially extended in spite of its length. This was not the first time Airbus had put its trust in item. “Having already worked with item before to create smaller test set-ups, we were familiar with its modular building kit system made up of aluminium profiles and accessories. The profiles are ideal for our project, because they are made of aluminium and are therefore magnetically compatible with the space probe. As a result, there is little – if any – magnetic interaction,” says Simon Tröndle, a systems engineer at Airbus.

The complete design based on the Stairway/Platform System from item served one key purpose – it was all about simulating gravity-free conditions.

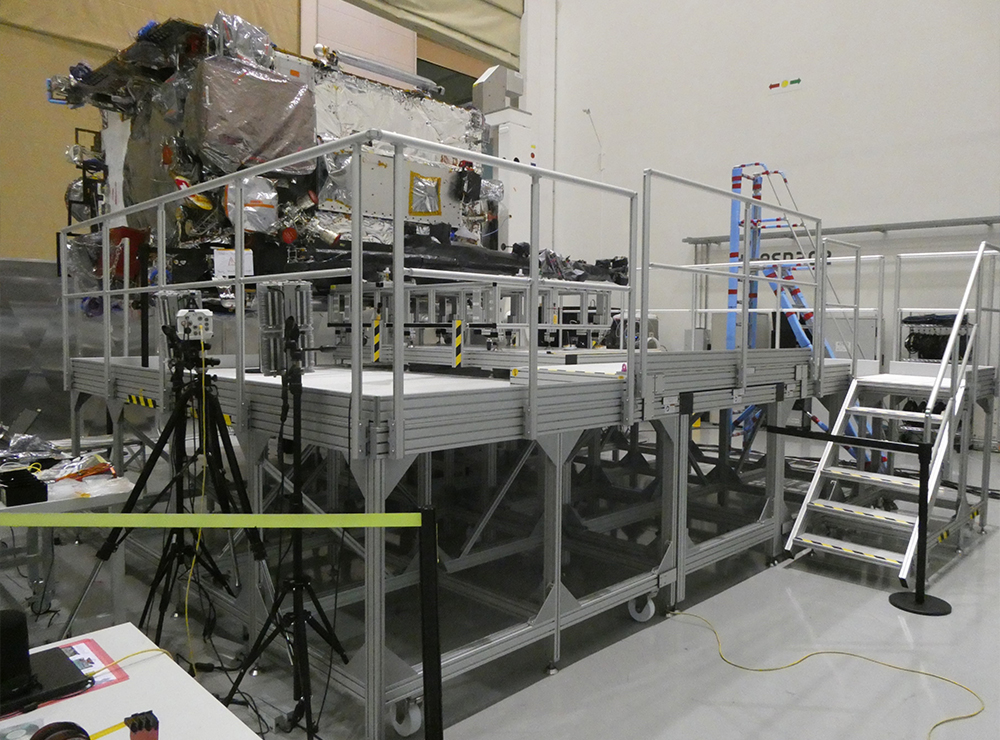

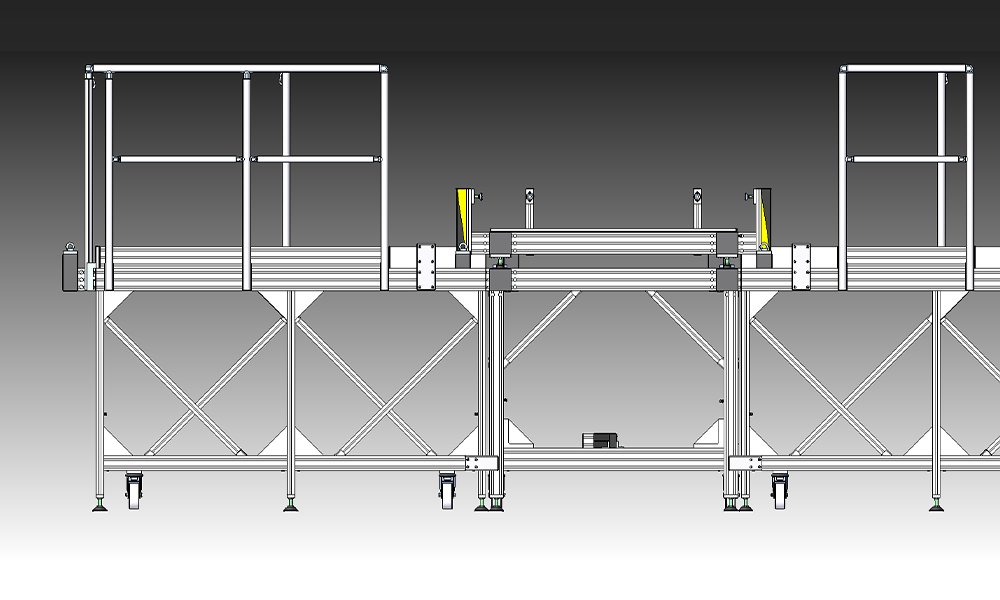

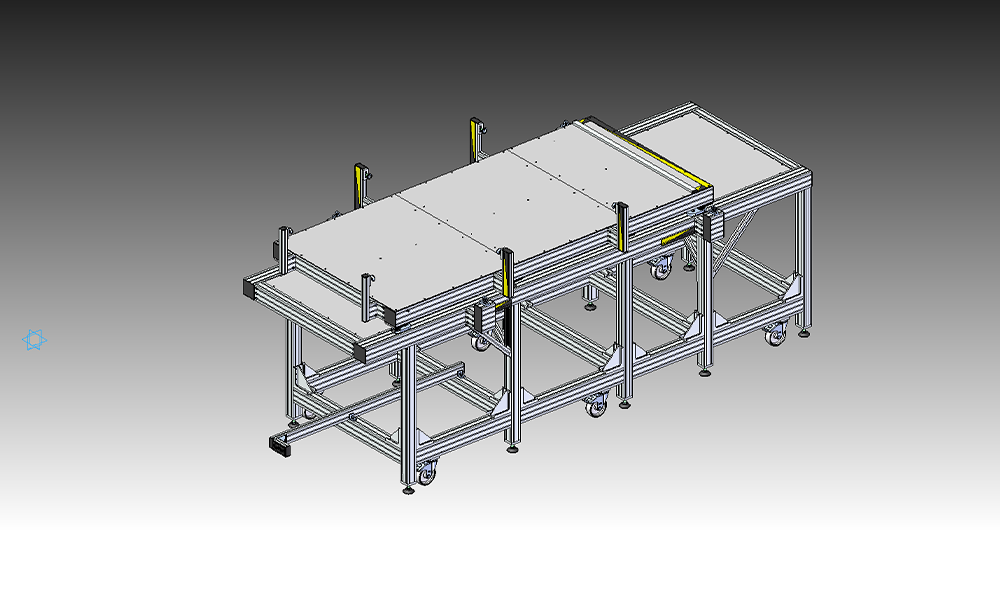

item supplied Airbus with a total of six modules, creating a platform that is around 5700 mm wide and 5330 mm long, has guard-rails at a height of 1300 mm and is accessible via a stairway. “Our overall system weighs approximately 2.8 metric tons and comprises over 4000 individual components. Completing it involved meeting all kinds of requirements, some of them highly specialised,” reveals Christian Kirchdorffer, who is responsible for customer solutions at item. The complete design based on the Stairway/Platform System from item served one key purpose – it was all about simulating gravity-free conditions. This was the only way of testing the deployment of the MAGBOOM under conditions that were as realistic as possible. The platform served as a substructure that provided optimal support for the MAGBOOM.

Special requirements – no transfer of vibrations, ESD-safe, cleanroom-compatible

The work area had to be completely mechanically isolated from the MAGBOOM’s substructure so that staff could carry out tests on the boom without transferring any vibrations or oscillations from the platform. All the components needed to be both stainless and cleanroom-compatible. When it comes to satellite production, full compliance with cleanroom requirements is standard. Since the substructure needed to be set up in a cleanroom, there were also special requirements that applied to the machining of the aluminium profiles. When profiles are cut to size, oil is frequently used for cooling purposes. As a result, residues and a film of lubricant can remain on the inside of the profiles, thereby contaminating the environment. However, when cutting its profiles, item uses isopropyl alcohol for cooling purposes, which evaporates without leaving behind any residues. The extremely clean profiles therefore satisfy cleanroom requirements.

Analyses were carried out to verify that structural requirements had been met. In addition to compliance with cleanroom and structural requirements, ESD safety was another must.

It was also vital for components to exhibit only minimal self-magnetism to prevent any risk of the structure falsifying the measuring results taken by the sensitive instruments. “Numerous fasteners had to be specially made from stainless steel, so we swapped components such as T-slot nuts, feet, angle brackets and screws made from conventional steel with stainless steel equivalents,” explains Joachim Pfeff, who is responsible for designing customer solutions at item. There were also various structural requirements to be met. The platform was designed for a load of 200 kg/m2. It was also specified that the deployment table at the very top – referred to as the “Rollerskate” – had to be able to support a static load of 100 kg. The Rollerskate was lifted onto the central platform and aligned there using a crane, so it also needed to withstand additional transport-related stresses. The elastic deformation of the surface was not to exceed 1 mm, and analyses were carried out to verify that structural requirements had been met. In addition to compliance with cleanroom and structural requirements, ESD safety was another must.

A safe platform – protection against occupational accidents and the transfer of vibrations

In terms of occupational health and safety, too, Airbus put its trust in the expertise and decades of experience item has. The substructure was designed in line with the applicable occupational health and safety regulations and standards, together with further requirements of the accident insurance and prevention institutions. By comprehensively factoring in all safety aspects, item created a safe working environment so as to specifically prevent falls and other accidents. In addition, item conducted a full structural analysis and calculated deflection for the individual components. Overall, the biggest challenge was designing a platform that transfers no vibrations whatsoever to the boom or measuring instruments. Several platforms were therefore built as separate modules. These are connected via a bridge to prevent any vibrations from being transferred. The Rollerskate rests on the central level of the platform at several points. Forces are dissipated into the ground.

Simple transport and reliable stability

All six modules (left-hand, central and right-hand platforms, bridge, stairway and Rollerskate) can be transported separately. The individual platforms are moved into the desired position with the help of the swivel castors fitted to the frame. Height-adjustable, anti-slip feet provide the necessary stability and also enable initial adjustment. There are three sets of adjustable feet for modifying the height of the central segment. The adjustable feet at the very bottom are used first, to make an approximate adjustment. Another platform that similarly has height-adjustable feet is placed on this central segment. Additional adjustable feet on the Rollerskate ensure that the height of the levels can be aligned with the utmost precision. What’s more, the ingenious system means the deployment plane can be adjusted to within 0.05°. This was a key requirement for the MAGBOOM deployment process.

Complete satisfaction with the logistics and customer service, too

The construction and assembly of the individual modules were comprehensively documented. Since it was initially unclear whether the modules would be transported by crane or forklift, appropriate measures had to be taken to cover both eventualities. “We were able to inspect and approve the entire solution on site at item. Only then were the individual modules painstakingly packed in specially made crates and transported to France,” reports Tröndle. “Besides the design, item therefore also took care of the logistics, providing us with excellent support throughout the entire project. We were, at all times, in close touch with a single contact, who adapted very well to our specific aerospace mindset in a partnership of equals. Despite the numerous and, in some cases, complex requirements, I rate the collaboration as highly productive and solution-oriented,” he concludes.

Do you want to keep up to date on the various ways that item products are being put to use? Then we have just what you’re looking for! Simply subscribe to the item blog by completing the box at the top right.