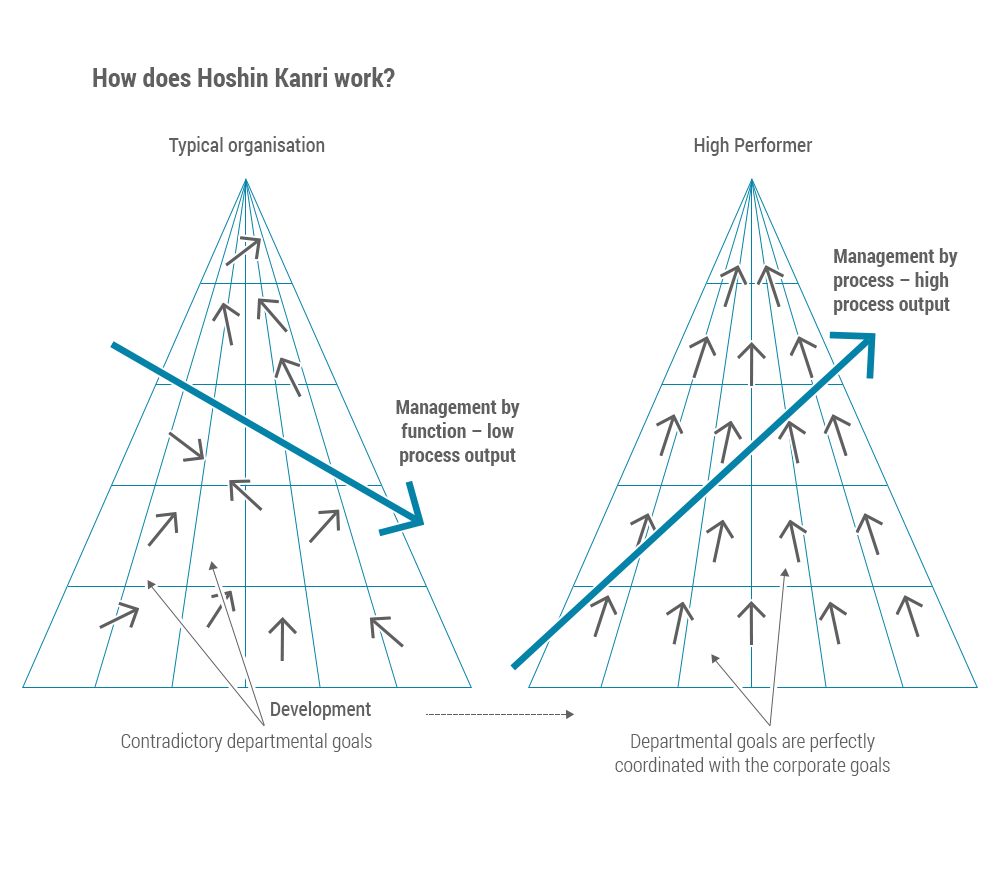

A company formulates a vision with the best of intentions, but actually realising this vision is a whole different ball game. Things often get lost along the way.

Factors relating to location (office versus Gemba, i.e. the place where value is added) and hierarchy (management versus staff) are normally to blame. Hoshin Kanri, however, is a lean production method that keeps the realisation of a corporate vision right on track and involves the entire workforce. “Hoshin” is the word for a compass needle, while “Kanri” means management. This management compass needle is a strategic process that extends vertically to span all levels of the hierarchy and horizontally to cover everything from strategic goals to individual measures. The following four steps are integral parts of Hoshin Kanri:

Defining a strategic plan

Developing tactics to implement it

Taking action

Reviewing the result and adjusting it if necessary

But how is Hoshin Kanri actually implemented?

The world of lean production

Less waste and more added value – lean production methods let you make targeted improvements to your production efficiency. Our white paper provides a compact introduction.

GET YOUR COPY NOW

Hoshin Kanri – structure

When defining a strategic plan, it’s advisable to specify no more than five objectives. Hoshin Kanri deliberately takes a long-term approach – with a small number of breakthrough objectives for a period of three to five years. A breakthrough objective is one that brings about fundamental changes at a company when it’s achieved. This shouldn’t be confused with the abrupt changes of Kaikaku, which is also referred to as “Breakthrough Kaizen”. SMART goals also play a key role. Easy to remember, this acronym stands for:

Specific: Define specific goals, that is to say target situations.

Measurable: Criteria that can be measured in concrete terms are a must.

Attractive: Goals should be motivating and meet with the approval of all staff.

Realistic: The target situation should be achievable with the available resources.

Time-based: Specify a precise deadline for achieving the goal.

Effectiveness is also crucial during the strategic phase. In this context, it’s important to make the following distinction: Effectiveness means doing the right things, whereas efficiency means doing things right. In other words, the wrong things can also be done efficiently – for instance, if someone misunderstands a task but still carries it out correctly based on this understanding. Since this wastes both time and resources, however, it’s vital to define Key Performance Indicators (KPIs). Ideally, these are displayed visually to make them easier to understand – on a dashboard, for example.

Hoshin Kanri – Catchball/Nemawashi process

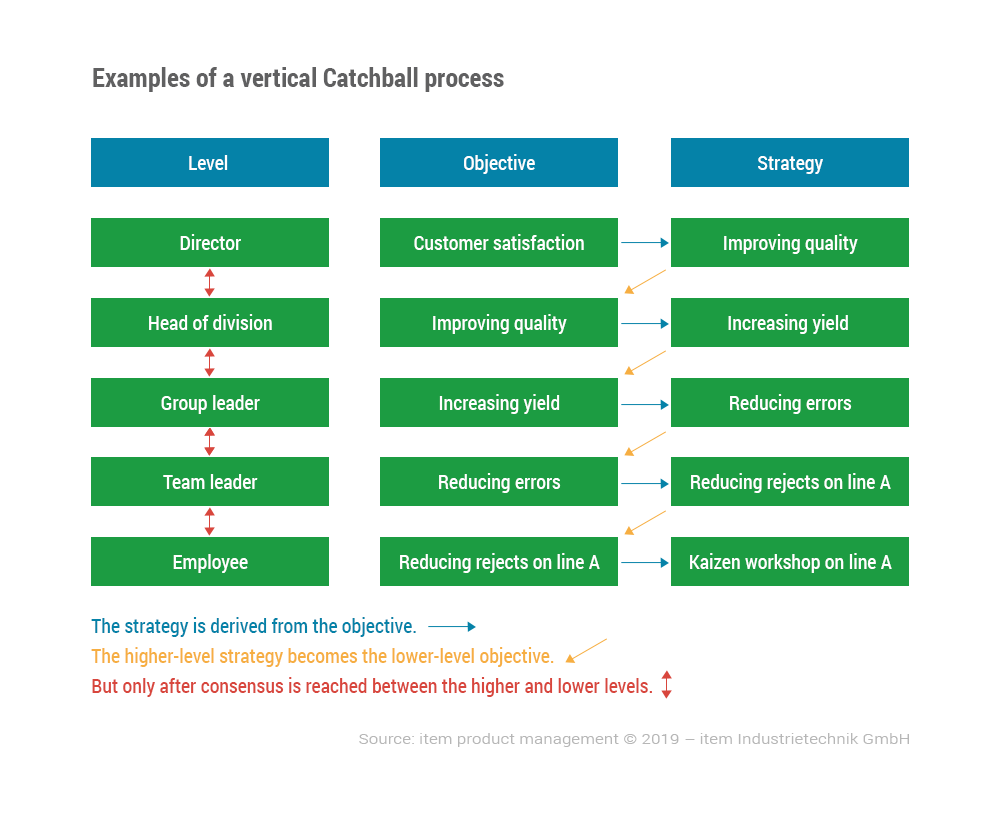

The main focus when it comes to implementation tactics is Catchball and/or Nemawashi. Catchball is the far more familiar term. It comes from a popular children’s game in which all the participants stand in a circle and throw a baseball to one another. This clearly illustrates the key concept of Hoshin Kanri’s Catchball process – no decisions are imposed from above. The management team and staff at all levels in the hierarchy develop the objectives together – and “pass the balls to one another”. Nemawashi makes it even clearer that this isn’t something that can be done in a hurry. Made up of the components “ne” (= root) and “mawasu” (= to go around something), its original meaning is to be understood literally – it refers to the process of digging around the roots of a tree in preparation for replanting.

During this process, it’s important to familiarise the tree with the soil at the new location early on to facilitate the transfer – clearly a delicate process. In the lean context, too, “the ground is prepared” gradually during Nemawashi. This specifically avoids the demotivation caused by making the people involved feel like they’ve been ignored. At the end of the day, the people actually carrying out an activity know best whether the targets set are realistic. Although the process of obtaining consensus normally takes longer with this approach, measures can be carried out much faster and in a far more targeted way, which motivates everyone involved.

Hoshin Kanri – advantages

Hoshin Kanri is implemented along the same lines as the PDCA cycle (Plan – Do – Check – Act). It’s an open-ended experiment. If Hoshin Kanri is to be successful, this means reviews are essential, as is a dynamic, positive approach to both feedback and mistakes. It’s the same as with all lean production methods – success depends on an in-depth understanding and the commitment of everyone involved. Although KPIs such as RoI (Return on Investment) or EBITDA (Earnings Before Interest, Taxes, Depreciation and Amortisation) are important, far from driving a company’s practices, they are in fact results of these practices. Hoshin influences processes and doesn’t focus solely on the outcome.

Hoshin Kanri also takes the customer’s opinion into account and not just profit targets. If implemented successfully, it improves the corporate culture, too. Catchball/Nemawashi is an explicit contrast to the top-down approach and is based on consensus. Resources, requirements and KPIs can be adapted to all objectives and levels at the company. Each and every employee becomes even more aware of their role and goals by being involved in setting targets, planning improvements and reviewing progress. This means staff at every level in the company hierarchy take on responsibility and leadership roles.

Are you interested in fascinating reports and innovations from the world of lean production? Then we have just what you’re looking for! Simply subscribe to the item blog by completing the box at the top right.