We have everything you need to know about designing conveyor belt systems, including tips for your production line! Get to know the key components, the different types of conveyor belts and the basic operating modes.

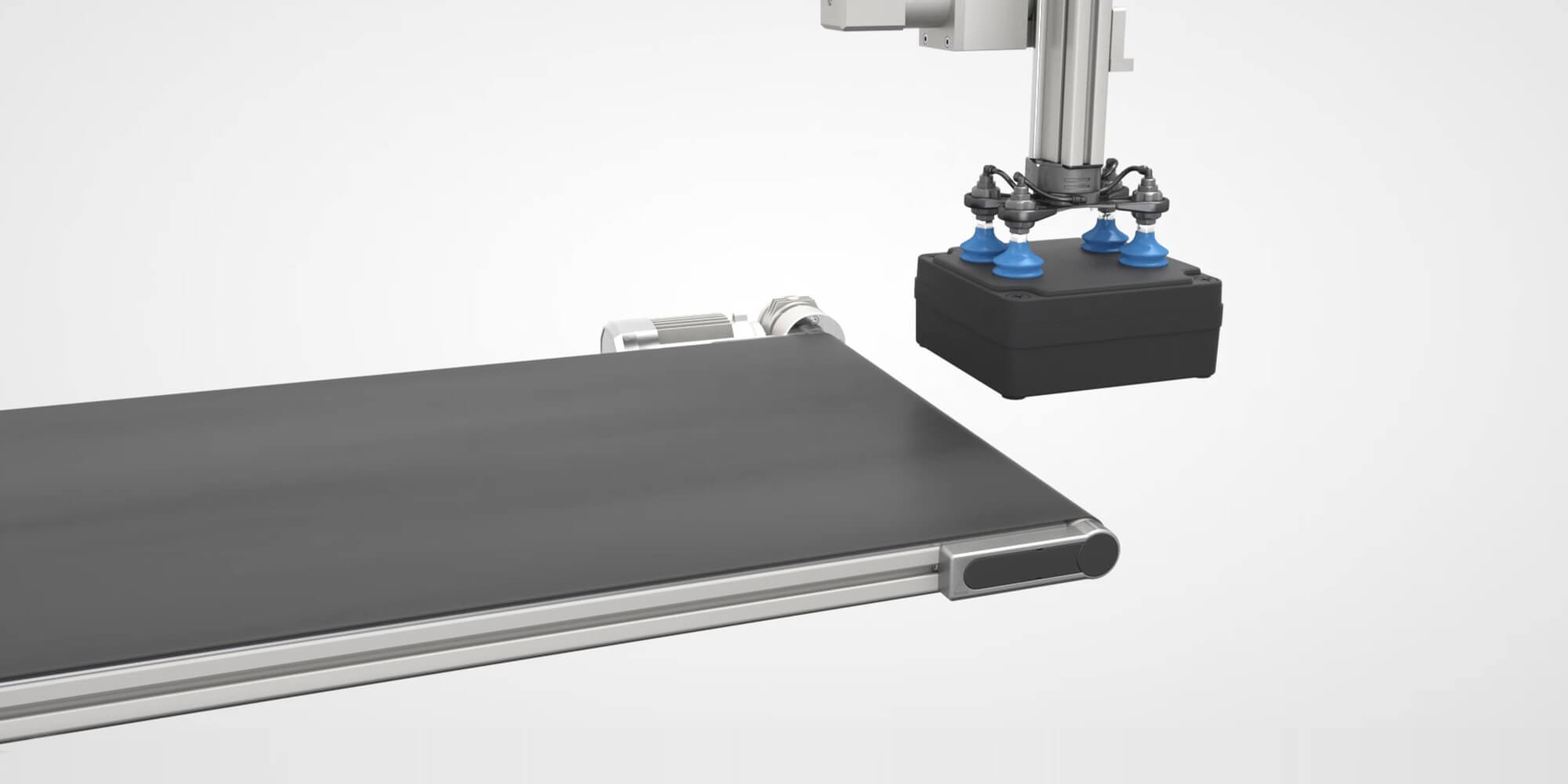

Your components have been packed in crates and now need to get to the dispatch section. Transporting them manually wouldn’t be efficient, because the crates are heavy and your staff need to remain at their packing stations. A timing belt conveyor is the ideal solution. It makes the process of getting the crates to their destination both automatic and dependable. If, on the other hand, it’s a case of continuously transporting screws to an assembly station, a flat belt conveyor is the best option. You can use conveyor belt technology to create a customised transport solution for any article.

There is an ideal conveyor belt for transporting everything from crates and bulk goods to sensitive electronic components. The large variety of products and requirements in conveying technology raises a number of key questions – how is an industrial conveyor belt system designed, what types of conveyor belts are available, and which conveyor belt is suitable for which application? This is where the advantages of the flexible item Conveyor Belt System really come into their own. This system fits in perfectly with your specific requirements. Its modular design ensures every component reliably reaches its destination. That’s a key prerequisite for efficient production processes.

Conveyor belt technology from item

Find out more about the item Conveyor Belt System. This overview will tell you everything you need to know about flat belt conveyors, timing belt conveyors, motors, gearboxes and accessories.

FIND OUT MORE NOW

Conveying technology – design and function of conveyor belts

At production and logistics centres, individual and bulk goods in different shapes, sizes and weights need to make their way efficiently from A to B. The objective is to use a conveyor system to transport these goods quickly and reliably to their destination. The item Building Kit System offers countless possibilities for customised conveyor belt solutions. You can ensure an efficient flow of goods, with or without accumulation, using our item Conveyor Belt System. Its durability and operating efficiency reduce your maintenance outlay, while also boosting your productivity. The modular design concept and compatibility with other item products means you can create conveyor systems, including peripherals (e.g. machine cabin, enclosure, etc.), that fit your needs perfectly. These systems can be geared precisely to the relevant transport operation – from autonomous conveyor lines through to conveyor sections integrated into existing systems.

The surface of conveyor belts can be adherent or non-adherent. Non-adherent surfaces support accumulation.

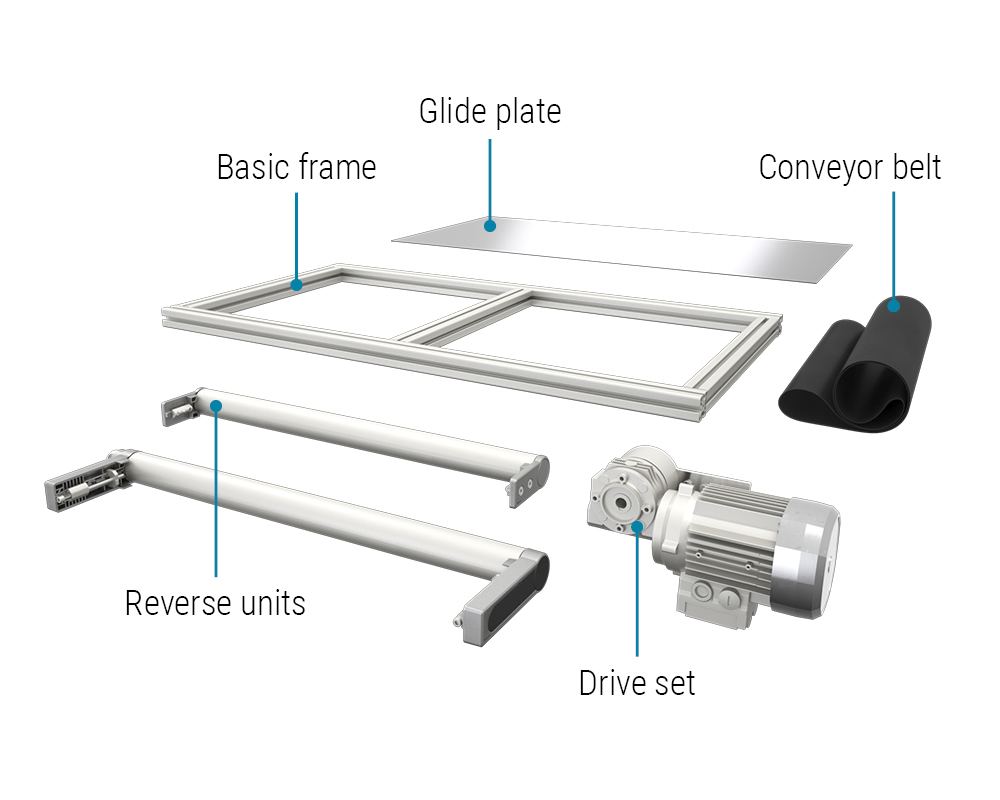

A typical conveyor belt system is made up of the following components:

- Basic frame: The base construction that supports the entire structure.

- Return pulley: Located at both ends of the conveyor belt, this pulley reverses the belt’s direction of travel.

- Glide plate: Providing a smooth surface on which the belt slides, this plate minimises friction.

- Flat conveyor belt / timing belt: The key element taking goods from A to B.

- Drive set: Powers the belt to transport goods.

The belt surface can be adherent or non-adherent. A conveyor belt with or without accumulation can be used, depending on the application. Non-adherent surfaces support accumulation, as the friction between the belt and the goods being transported is lower. If the individual goods are stopped (accumulated) on the belt, the smooth belt will continue to move underneath them. This means additional steps can be undertaken, such as attaching a label or using a camera to carry out a quality control inspection. It also ensures the goods being conveyed move about more easily on the belt. A conveyor belt with an adherent surface does not support accumulation. It is suitable above all for simple transport operations and heavy loads. The greater adhesion also copes with upward and downward gradients. Before purchasing and assembling your conveyor belts, you should ask yourself whether upward or downward gradients are involved and whether you want your components to accumulate.

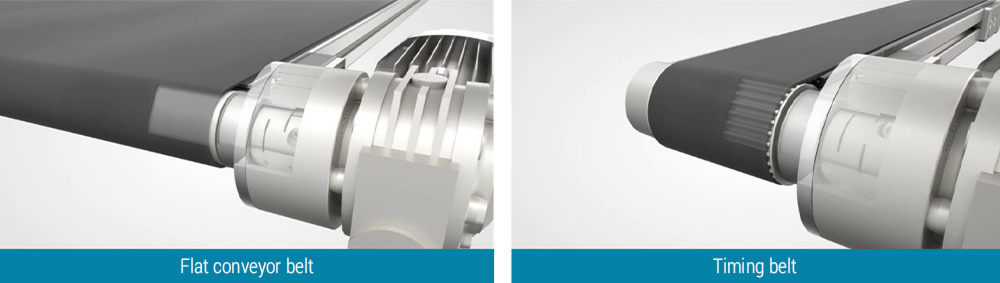

Flat belt conveyor vs. timing belt conveyor for transport operations

Flat belt conveyors are particularly suitable for light to medium loads. The mechanically locked connection of timing belts means belts with a smaller width can move heavier loads. We offer both single and double variants of the relevant conveyors. You can use our Flat Belt Conveyor 8 40 D for high-precision conveying of workpieces with different shapes. It is available in eight widths up to 400 mm and in lengths of up to 6000 mm, with transport speeds ranging from 2.5 m/min to nearly 30 m/min. One key feature of the flat belt conveyor is its glide plate, which serves both a protective and a supporting function and also improves the belt’s wear resistance. Flat belt conveyors are available with either an adherent or a non-adherent surface. The portfolio also includes belts exhibiting low static friction that allow individual goods to accumulate. In non-accumulating systems, on the other hand, belts with an adherent surface can be used to transport workpieces continuously at a gradient of up to 20°. Flat belt conveyors also make it easier to remove production goods. Other possible applications include interlinking several systems, and sorting and separating parts.

The mechanically locked connection on the drive pulley means timing belt conveyors with a smaller width can transport heavier loads.

Timing Belt Conveyor 8 40 D is the best choice for transporting heavy goods. It is available in a width of 40 or 80 mm. Its side guides keep the industrial timing belt running securely along the timing belt guide strips, even when subjected to lateral forces. The drive pulley creates a mechanically locked connection and transfers heavy loads to the belt. The timing belt is available in an accumulating and a non-accumulating version. Timing belt conveyors are ideal for cycled transport operations, in which workpieces are moved at fixed intervals. They are also perfect for operations with high process requirements and for separating parts. If you are intending to transport dimensionally stable individual goods, you should use the double variant of the flat belt conveyor or timing belt conveyor.

Suitable applications for double variants

Double variants of conveyor belts offer unique benefits, such as easy access to the underside of the individual goods. What’s more, you can use the area between the two belts for further process steps. Camera systems located in this gap can easily record workpieces or cartons. This access makes it possible to scan barcodes, too. The space can also be used to install sensors and actuators underneath the individual goods. Another simple option is using the area in the middle for the accumulation and release of workpieces, giving you additional flexibility. The width of these double variants can be customised to suit your specific requirements, i.e. to the width of the workpiece, cartons or transport box. Essentially, double conveyors are suitable for everything from light to heavy loads. This versatility makes them valuable assistants in automated production.

Side guides make conveying safer by helping the durable timing belt with its integrated steel wires withstand lateral forces.

Two conveyor belts that can be spaced anything up to 2400 mm apart make Double Flat Belt Conveyor 8 40 D an exceptionally versatile conveyor option. The synchronised belts help you move inherently stable products efficiently from A to B. The gap between the two belts provides space for installing sensors and actuators below the individual goods. Double Timing Belt Conveyor 8 40 D is available in two belt widths and in lengths of up to 6000 mm. As with the double flat belt conveyor, the synchronised belts can be spaced up to 2400 mm apart. Side guides make conveying safer by helping the durable timing belt with its integrated steel wires withstand lateral forces. The stable load-bearing frame with four freely accessible Line 8 grooves makes it easier for you to carry out work such as attaching accessories, connecting stands and integrating the belt into machines and systems. With this variant, too, you can fit sensors and actuators below the individual goods, in the space between the two conveyor belts.

ESD-safe conveyor belts for industry

One characteristic feature of conveyor belts for industry is their continuous relative movement between the drive pulley and glide plate. During this process, different materials rub against each other and separate again, building up electrostatic charges. These are equalised in the form of an electrostatic discharge (ESD). You can reduce this risk using the item Conveyor Belt System, which we have expanded to include ESD-safe flat conveyor belts and timing belts. ESD-safe conveyor belts are constructed in such a way that they prevent and dissipate electrostatic charges effectively. You can combine these with the appropriate item conveyor for all-round ESD-safe transport. One particularly practical possibility is configuring your ideal conveyor belt solution in the free item Engineeringtool. With or without ESD protection, as a standalone conveyor belt or in combination with other item constructions – anything is possible with this time-saving online tool.

With our ESD-safe conveyor belts, you will find your perfect solution for the diverse requirements in production environments.

Flat Conveyor Belt PUR ESD, accumulating is ideal for item flat belt conveyors. It doesn’t build up a charge, even when subjected to friction. A stainless steel glide plate fitted underneath the belt safely routes any charge to the earthing system of the motor. The robust surface also benefits from reduced static friction. This belt is available in eight widths ranging from 40 to 400 mm. Timing Belt T5 PA, accumulating is available for item timing belt conveyors. It boasts a low-friction surface that is ideal for accumulation. With this variant, too, any charge is dissipated by ESD-safe timing belt guide strips. You can choose between a width of 40 or 80 mm. Thanks to the different variants of our ESD-safe conveyor belts, you can be sure you will find the perfect solution for the diverse requirements in production environments. A test certificate provides you with confirmation of compliance with the defined limits.

Are you interested in conveyor belt technology in industry? Then we have something that’s right up your street! Simply subscribe to the item blog by completing the box at the top right.