The State Academy of Art and Design (ABK) is using a special construction made up of linear technology components from item to analyse paintings.

The ABK in Stuttgart is one of Germany’s oldest, largest and most prestigious public art schools. Besides departments for architecture, design and art, it also has a Department of Conservation – Art History. One of this department’s five study programmes is devoted to the conservation and restoration of paintings and polychrome sculptures. Together with the city art museum, Staatsgalerie Stuttgart, the ABK uses X-ray diagnostics to examine paintings. With the help of X-rays, works of art are examined for their art-technological structure and materiality, as well as their authenticity and condition. Having previously used an analogue X-ray system, the ABK purchased a digital system in 2020. “However, we also needed a positioning unit to be able to move paintings to the cassette with the phosphor plates. When looking for a suitable partner to help us with this task, I came across item. Together, we developed a positioning unit based on linear technology,” says Peter Vogel, a qualified restorer and an academic associate at the ABK.

item linear technology at a glance

Find out more now in our factsheet. It provides you with a compact overview of solutions, components and the numerous uses of item linear technology.

GO TO THE FACTSHEET

Digital X-rays and linear technology make work easier

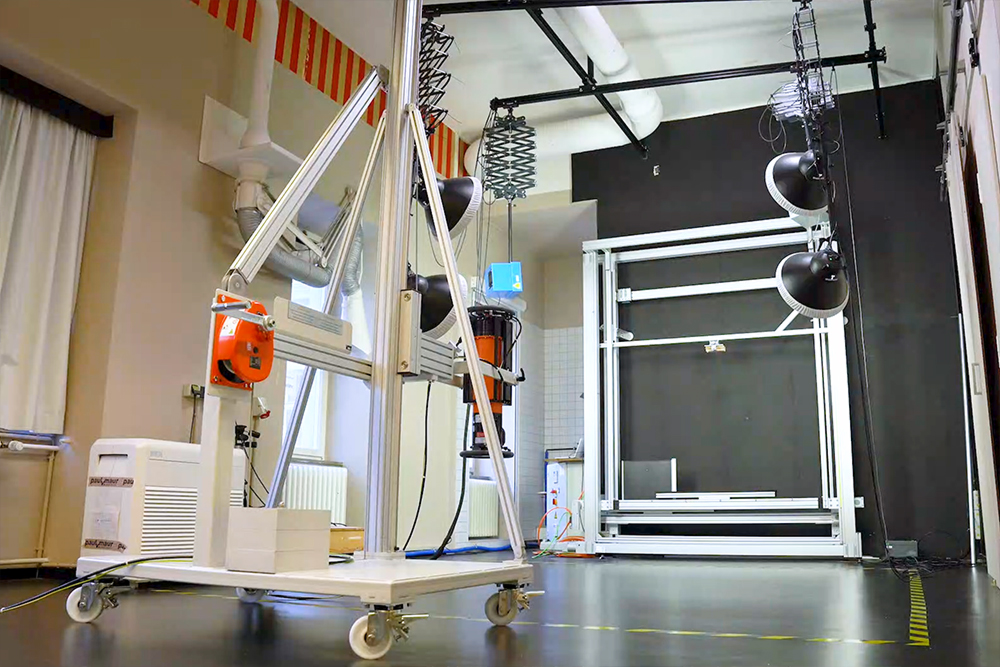

The set-up resembles a kind of easel, on which the painting or the digital imaging plate can be moved horizontally and vertically as required. Both the ABK and Staatsgalerie Stuttgart now have a unit of this type for a variety of examination purposes. “Analysing pictures was previously a time-consuming process using an analogue X-ray unit. They had to be laid flat on a horizontal working surface,” explains Vogel. With the previous analogue process, X-ray technology was used to take numerous individual photographs on films that had to be aligned by hand. These analogue X-ray images were then developed, scanned in and, finally, combined using image processing software – a laborious and lengthy process.

The X-ray equipment is set up at a distance of up to four metres from the positioning unit and stays there the whole time.

That has now changed. The positioning unit for the digital X-ray examination of artworks consists of two vertical sections. The picture is located in the rear section and the front section is used for the cassette containing the phosphor plate that is required for the X-rays. The X-ray equipment is set up at a distance of up to four metres from the positioning unit and stays there the whole time. Due to the significantly larger distance, a much better imaging geometry is achieved. Pictures up to a size of 117 x 160 cm are secured within a special frame. With the help of item linear technology, they can be repositioned precisely by a set increment and moved to the defined positions.

Versatile special construction for X-ray images of artworks

After each exposure, the cassette is automatically moved to the defined removal position. It is pushed into the X-ray scanner, where the phosphor plate is removed, read out, stored, and then deleted and reinserted. Afterwards, the cassette is put back into its holder, whereupon it moves automatically and precisely to the next position. The size of the cassette (35 x 45 cm) means several X-rays have to be taken to cover an entire painting. In the case of particularly large works of art, it is also necessary to move the X-ray equipment and phosphor plate synchronously. The construction, which has a width and height of 2.50 m, is ideally equipped for this purpose.

Its positioning unit consists of four axes, with one motor controlling the horizontal linear guide and another controlling the vertical one. This is where the item linear system comes in – a complete solution comprising a linear unit, motor, gearbox and controller. The system being used in this instance, Linear Unit KLE 8 80×80, has a concealed timing belt to ensure reliable protection for the staff operating it.

Since there are no enclosures, we use a concealed timing belt to maximise safety and prevent crushing or other injuries.

Alexander Knoll, a project manager and product expert at item, explains the thinking behind the solution: “This is not a mechanical engineering environment. Since there are no enclosures, we use a concealed timing belt to maximise safety and prevent crushing or other injuries.” What’s more, the virtually maintenance-free system produces no contaminants whatsoever. The precision of the item linear system rules out any damage to paintings resulting from the construction itself or the control of the linear units. These units also ensure the ideal implementation of vertical and horizontal movements, along with a good balance of forces. “We needed to create a construction that can also transport a corresponding load vertically. That was a particular challenge, one that we solved using a special transmission,” explains Knoll. Besides carrying its own weight, the construction can thus also move technical equipment or paintings weighing up to 30 kg. It supports horizontal travel of up to 1600 mm and vertical travel of up to 1800 mm.

An easy introduction to the world of linear technology

Thanks to item MotionSoft® software, commissioning the linear axes was a very quick process. The combination of cost-efficient design and user-friendly software means it takes no time at all to get started with linear technology. “A standard laptop can be used to operate the system. After a short familiarisation period, operators are able to move the axes and also carry out simple programming,” emphasises Knoll. The online tool gives users precise details about which waypoint to approach, for perfect control across all processes. The solution can also be connected to a higher-level control system. “Following an initial test phase, we are currently in the process of establishing a system of this kind. That will also make it easier for people who don’t work with the positioning unit all the time to operate it,” says Vogel.

It’s much easier for us to examine small paintings and also larger ones. The entire process has been made far simpler and the time required has almost halved.

The lightweight and stable structure is ideally geared to the space available. For example, the linear axes themselves from the frame of the construction. All axes have coloured markings for better visual orientation. Additional aluminium profiles act as the frame for smaller paintings. The entire holding structure moves horizontally and vertically on a carriage. Overall, the positioning unit thus offers a whole host of possibilities for paintings of various sizes. “It’s much easier for us to examine small paintings and also larger ones. The entire process has been made far simpler and the time required has almost halved,” explains Vogel. Distorted X-rays are now a thing of the past. The new X-ray process for analysing artworks supplies digital images that can be used straight away – all that remains to be done is to combine them. Since there is normally no longer any need to move the X-ray equipment, handling is much more convenient and far safer than before.

Flexibility, ergonomics and an aesthetically appealing design

The positioning unit based on item components is also perfect for methods of microscopy and infrared reflectography. The microscope is attached to the front carriage, while the painting is located in the rear section. Having the flexibility to reposition the microscope to suit the operator’s height meets the requirement for ergonomic working conditions. Even when analysing large pictures, the positioning unit ensures every section can be examined. “Although it’s rather unusual for artworks to be analysed standing upright rather than lying flat, this technology makes it easy and convenient for us to reach even the centre of the picture,” emphasises Vogel.

Although art and linear technology don’t have much in common per se, this industrial technology now gives us an ideal starting point for our work. item has been a big help to us and has succeeded in combining these two different fields.

Besides outstanding functionality, the system as a whole also features an aesthetically appealing design. That’s because combining form with function in product development has been a top priority for item from day one. Making subsequent changes is remarkably simple, too, as the structure can be flexibly extended and thus adapted to new requirements. In summing up the successful project, Vogel also mentions customer service and the merging of different worlds: “We were in close contact with item throughout the entire project planning and test phase. Although art and linear technology don’t have much in common per se, this industrial technology now gives us an ideal starting point for our work. item has been a big help to us and has succeeded in combining these two different fields in a useful way.”

Want regular updates about linear technology applications? Then we have just what you’re looking for! Simply subscribe to the item blog by completing the box at the top right.