From the design phase, documentation and coordination to ordering – the item Engineeringtool optimises the entire process chain.

CAD programs are often a bit unwieldy for standard tasks relating to constructions made from aluminium profiles, for example in factory equipment engineering or to create base frames. What’s more, they also lack the specialist knowledge of a supplier when it comes to aluminium fasteners and accessories. The item Engineeringtool, on the other hand, is something we have developed ourselves and into which we have poured our decades of experience. It stands out for its intuitive user navigation and rules-based 3D design. Automatic links and filters ensure that design and engineering tasks can be completed much faster than in a CAD system. Users can draw on the MB Building Kit System and Lean Production Building Kit System, not to mention components from the item Work Bench System, and can simply use drag and drop to place the products they want in a 3D view, where they can put their design together. Solid panel elements are now also available, making it possible to design applications such as material-optimised benches, workshop trolleys and machine cabins in the tool. The free design software for aluminium profiles can be used directly in your browser without needing any additional software or installation.

item Engineeringtool: Support for everyone, from beginners to experts

Whether you are looking for basic information about the item Engineeringtool or details of the latest innovations, you will find everything you need here and much more besides, including preconfigured solutions and a direct link to our specialists.

FIND OUT MORE NOW

Focusing squarely on time savings and user-friendliness

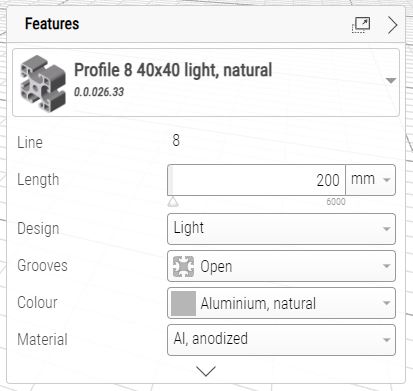

All the functions of the item Engineeringtool have been designed to make life easier for users. This begins with the product catalogue, which uses numerous filters to ensure the appropriate product can be found for any planned application. Thanks to the calculation tools, users can rule out the danger of making the project too big or too small. In the case of aluminium profiles, for example, these filters and tools come into play for aspects such as contours, groove shape, groove type, product line, design, length and profile deflection or buckling. As a result, users don’t need to know the specific aluminium profile that will be used in the design from the outset. The item Engineeringtool uses the information provided to determine which profile meets the requirements. Using aluminium profiles to create the actual design in the software is also straightforward – simply drag the product you want from the catalogue and drop it on the 3D work area.

Standard tasks can be completed as much as 94% faster in the item Engineeringtool compared to using a CAD system.

Any errors in the design are flagged up immediately with visual cues. A warning indicates the problem, and the item Engineeringtool also helps correct the mistake. When the design is finished, the technically correct result can be ordered in the item Online Shop. The “Properties” window makes it possible to configure products in just a few clicks and use parameters to define their properties. For example, you can change profile length using a slider or by entering the length manually. Ultimately, standard tasks can be completed as much as 94% faster in the item Engineeringtool than using a CAD system.

Intelligent functions of the design software for aluminium profiles

Fasteners offer a perfect example of the extent to which the design software for aluminium profiles reduces the complexity involved. All that is required is to drag a standard Fastener onto a Line 5 profile, for example. The software recognises the profile and automatically selects the Line 5 Standard-Fastening Set, including all the associated thread-tapping work and connection processing. However, there is an even easier way. You can use the “Preferred fastener” window to choose between Automatic-Fastening, Standard-Fastening and Universal-Fastening Sets. If you have made a selection here, the design software automatically connects the aluminium profiles together once they are placed on the work area.

It’s easy to duplicate recurring design steps – a double click selects and copies the components, so basic frames are created in next to no time.

– Torben Hohgräve, product owner and expert for online tools at item

Caps are also selected automatically. Once users have selected the Cap in the product catalogue and dragged it to the end of a profile, the design software adds the suitable Caps by itself. The same applies when it comes to adding floor elements such as Swivel Castors. Screws and other fastening materials do not have to be defined separately, as the online tool automatically adds small parts. Time-saving functions such as these mean nothing distracts users from the task at hand. It’s easy to duplicate recurring design steps, too – a double click selects and copies the components, so basic frames are created in next to no time. You can use your keyboard to enter lengths for each component to ensure they all connect precisely. The lock function then ensures these cannot be changed.

Benefits in the documentation, coordination and ordering stages, too

The item Engineeringtool also offers the potential to save time with the documentation, too. On average, this can take up to two hours. Since the software for designing constructions made of aluminium profiles automatically generates the documentation in a very short time, users have more time for tasks that actually add value. The documentation is available in compact, detailed and complete versions. Among other things, it includes a parts list, a detailed machining plan, a multiview projection, an isometric drawing showing all dimensions, an exploded view and an assembly guide. What’s more, every design that is placed in the shopping cart is automatically assigned a globally unique project number.

The completely digital process chain helps prevent transfer errors and misunderstandings during coordination. Above all, though, it significantly reduces the throughput times for design projects.

This Cx article number is all that is required to order the design or to view it in the Projectviewer. Everyone involved in the project can therefore use this number to access the design and all the additional information, making coordination much easier. The result is a process chain that is digital from end to end – from the design phase and compiling the data to transferring the data into the documentation and placing the design in the shopping cart. This helps eliminate transfer errors and misunderstandings. Above all, though, it significantly reduces the throughput times for design projects. The straightforward ordering in the item Online Shop and rapid availability of item components ensure the machined profiles and associated small parts can be shipped within a very short time. As a result, customers can get the construction into service very quickly.

Are you interested in digitalisation and what the future holds for mechanical engineering? Then we have something that’s right up your street! Simply subscribe to the item blog by completing the box at the top right.