Electrostatic discharge can quickly lead to expensive consequences, but it can be prevented using targeted safety measures.

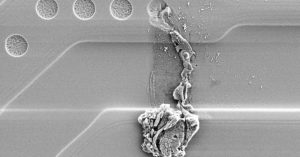

Since it frequently causes expensive damage and still generally goes unnoticed – at least until the consequences become evident – some people call it the “invisible danger”. We’re talking about electrostatic discharge (ESD), which is the name given to any uncontrolled equalisation of electrical charges between two objects – such as a hand and a doorknob – with different voltages. As electrostatic charges are basically building up all the time and an uncontrolled discharge can occur even without direct contact, electronic components are at risk at every stage of the production chain – unless they are protected using appropriate ESD safety measures.

ESD safety measures – it all starts with the supplier

The first ESD safety measures should be taken by whoever is first in the process chain. After all, it doesn’t matter how good the protection is in the processing plant if the components have already been damaged by ESD at the supplier’s end – especially since this kind of damage is invisible to the naked eye and is therefore difficult to detect. No wonder, then, that DIN EN 61340-5-1 prescribes a documented protection procedure for the entire process chain (from the supplier to the end customer). This document is part of the DIN EN 61340 series of standards and contains the requirements for effective ESD protection, along with valid limit values for the relevant test methods.

Alongside standard-compliant protective clothing and an ESD protection zone, it is also important to have well-trained staff.

For companies that value professional ESD safety measures, there’s really no way round DIN EN 61340-5-1. In addition to the documented protection procedure already mentioned, it also specifies well-trained staff (in terms of ESD protection), ESD protection zones set up as per industry standards and standard-compliant protective clothing. Employees working with components that are sensitive to ESD must therefore do so in a specially designed ESD protection zone, or “electrostatic protected area” (EPA). All materials used within the EPA must be electrostatically dissipative and earthed to the same potential, to reliably prevent electrostatic build-up and differences in potential.

Training is an important ESD safety measure

It is also possible to take ESD safety measures when transporting and storing electronic components – in fact, they are especially important in these situations. After all, movement and friction also cause electrostatic build-up. Components that are sensitive to ESD should therefore be transported and stored in special protective packaging that prevents uncontrolled potential equalisation. Where possible, a relative humidity of at least 30 percent should be maintained in the areas requiring protection. The use of ionising units in the goods receipt area is also helpful. These devices neutralise electrostatic charges, making them ideal ESD safety measures.

Once the components are in intralogistics, electrostatically dissipative transport and material supply trolleys such as item SystemMobiles are perfect. An ESD Drag Chain enables these to maintain constant contact with the ESD floor, while antistatic roller elements further enhance the ESD-safe design of the trolleys. All these ESD safety measures are of little use, however, if not all employees have the right training. Effective ESD protection can only be achieved when everyone is pulling in the same direction. Our detailed blog entry on the basics of ESD safety is a good place to start when it comes to raising awareness of dangers of ESD, as it explains these in simple, easily understandable terms.

Interested in applications and solutions for ESD safety? Then we have something that might just help! Simply subscribe to the item blog by completing the box at the top right.