Task-specific work bench planning must never lose sight of the human factor. After all, not all employees need the exact same things from an assembly workstation, which is why benches need to be designed around both the process and the worker – and therefore follow ergonomic principles. What’s more, when several staff members will be sharing one workstation, it’s best to opt for an industrial work bench that can be rapidly and easily adapted to the physical proportions and capabilities of each individual. If the work allows, staff should be able to vary their working position, alternating between standing and sitting. After all, spending several hours in the same posture can result in muscle tension and even pain. Ideally, work benches for industrial use should therefore be (electrically) height adjustable. On top of that, there are numerous other aspects to consider such as fixing options, material supply, power/data supply and lighting. If electronic components are to be handled at the bench, then ESD safety needs to be factored in, too.

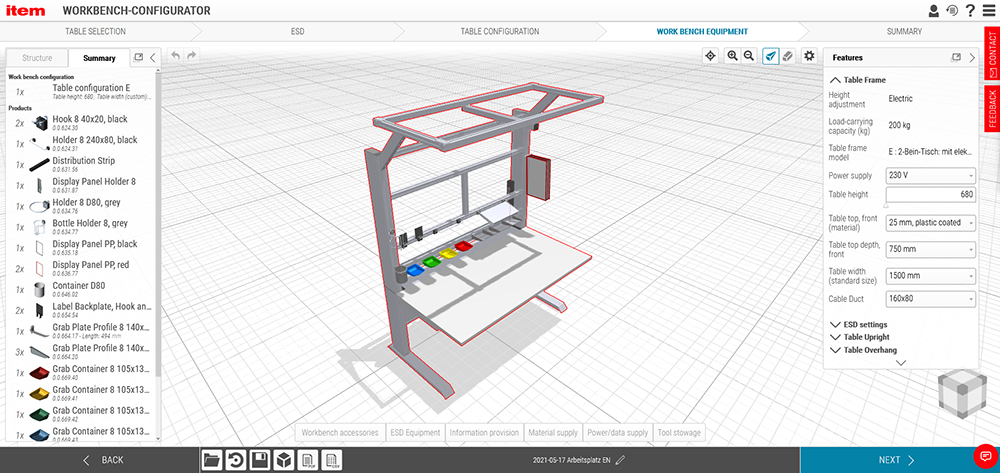

All in all, planning a work bench for industrial use – and the accessories to go with it – can be a time-consuming task. When using the revolutionary Work Bench Configurator from item, the whole process is faster and easier than ever before – thanks to a 3D view, intuitive drag-and-drop controls, a wide range of smart functions and the option to generate project documentation automatically at the touch of a button. Moreover, users can make the most of various pre-configured models for industrial work benches, which makes it even easier to get started. One particular highlight is the visualisation of Electrostatic Protected Areas (EPAs).

Configure industrial work benches online

Discover what the new Work Bench Configurator with its 3D view and smart functions can do – especially for ESD safety. Put together your very own manual production work bench without leaving your browser.

FIND OUT MORE

Plan industrial work benches more easily and quickly than ever before

User friendliness is a major hallmark of the Work Bench Configurator and is clear to see right from the very first step – selecting the table. Users don’t need any prior knowledge about the industrial work benches that item supplies, and can find out all they need to know by clicking on-screen info dots. At the same time, all the crucial details are also shown on the left, where a special filter removes table configurations that don’t fit the requirements that have been entered.

Users are guided through the process efficiently, but are still free to make whatever decisions they see fit.

Once a table model has been selected, users need to decide whether it ought to be electrostatically dissipative. By deciding at this early stage, they ensure that this sometimes critical characteristic is not overlooked. If the bench being planned does not need to be ESD-safe, all users have to do is click “No” – and that’s that. These two steps (selecting a table model and deciding on ESD safety) are excellent examples of how the Work Bench Configurator works – users are guided through the process efficiently, but are still free to make whatever decisions they see fit.

Work Bench Configurator delivers clear cost and time savings

The selection menu for product configuration offers numerous settings options on issues such as power supply, table height and width, the dimensions of the Cable Duct, ESD safety and the Table Upright and Overhang. As the configuration process is so clear, users are never overwhelmed by details that aren’t yet relevant. A particularly practical feature is that the height and width of the industrial work bench can be entered both manually and by adjusting a slider. When deciding on the width of their work bench, users can also choose from standards sizes (1200, 1500 and 1800 mm). Whether they opt for a custom width or standard width, delivery time is unaffected – digitalisation has made bespoke solutions standard, thereby saving time and money. The next stage is to select work bench equipment. Users simply drag and drop the components they require onto their industrial work bench.

Since every project has a globally unique project number including a clickable QR code and dedicated URL, sharing and discussing it with colleagues online couldn’t be simpler.

The next stage is to select work bench equipment in a special 3D work area with continuous zoom. Users simply drag and drop the components they require onto their industrial work bench. This is where they can delve into the huge scope of the item Work Bench System. The catalogue is regularly expanded.

The Work Bench Configurator automatically adds the necessary fixings. Moreover, users can even choose whether the accessories should be installed prior to delivery, which ensures the solution can be put to use faster and more dependably. Touches like these mean the Work Bench Configurator doesn’t just speed up the custom planning process, but the entire project. At the end, complete project documentation is generated with a single click. This contains the parts list, an isometric view, a multiview projection, an exploded view, an assembly guide for installed accessories and, if relevant, ESD documentation and an overview of ESD measurement points.

Since every project has a globally unique project number including a clickable QR code and dedicated URL, sharing and discussing it with colleagues online couldn’t be simpler. The CAD data for the project can also be downloaded with just a click. It is similarly straightforward for users to add their bespoke industrial work bench to the cart and place an order.

Unique functions for designing ESD-safe industrial work benches

The item Work Bench Configurator is an online tool with unrivalled functions for anyone wanting to plan an ESD-safe industrial work bench. The focus on ESD first appears when users are asked whether their solution needs to be ESD safe. If they answer “Yes”, this focus is maintained throughout all subsequent steps. If they answer “No” they can still change their mind at any point thereafter. All it takes is a click of the mouse to reactivate all the ESD setting mechanisms, thereby swapping out the table top for an ESD-safe version, for instance, and adding an ESD Central Connection for dissipation or as a measuring point. One particularly practical feature is the option to define the Electrostatic Protected Area (EPA), which is then visually depicted on screen.

The ESD documentation guarantees that the industrial work bench supplied is electrostatically dissipative to DIN EN 613-40-5-1 and that the stated ESD measurement points have been checked.

The Work Bench Configurator even allows users to define the entire industrial work bench as an EPA or, alternatively, configure very precise settings by using stepless sliders or by manually entering measurements for the height of the EPA (top and bottom). If a non-dissipative part is placed within the EPA, a yellow warning appears. This gives users a chance to decide whether to move the components in question or tolerate them, or choose not to have them installed. In the latter case, the components are simply packed up well and enclosed with the solution. These products are flagged up in the ESD documentation as a precaution. All in all, this guarantees that the industrial work bench supplied is electrostatically dissipative to DIN EN 613-40-5-1 and that the stated ESD measurement points have been checked.

Do you want to stay up to date with assembly work bench developments? Then we have something that’s right up your street! Simply subscribe to the item blog by completing the box at the top right.