From the work bench and chair to clothing and accessories such as ESD wristbands and tools – everything you need to know about the ideal equipment for an ESD workstation.

ESD stands for “electrostatic discharge” – in other words, the uncontrolled equalisation of electrical charges between two objects with different charges. Although the threshold for human perception of ESD is 3500 volts, a discharge of just five volts can be enough to damage sensitive electronic components such as the read heads of magnetic hard disks. Furthermore, a voltage as low as 100 volts is enough to wipe all the data from a magnetic data storage device or destroy an electronic memory cell. ESD damage is also invisible to the naked eye. Another important factor is that dangerous discharges can occur at many points in the process chain – even without direct contact.

Discharges can occur at any time – from the receipt of electronic components right across all production steps to the moment when the product is delivered to the customer. In many cases, affected components are not rendered unusable immediately. The damage they have sustained is therefore not apparent at the quality assurance stage, meaning that they are still delivered and used. As a result, ESD damage can lead to complaints and be detrimental to a company’s reputation. ESD is caused by many different factors, including movement and friction – unless working surfaces, accessories, tools and transport trolleys have been specially designed with ESD safety in mind. However, what specifically needs to be borne in mind when planning and setting up an ESD workstation for manual assembly?

Guide: The 10 golden rules of ESD safety

Specialist expertise in all aspects relating to effective protection against ESD at the workstation, presented in a compact format that includes a practical checklist for continuously enhancing ESD safety in your company.

Get the white paper now

Relevance of the electrostatic protected area (EPA)

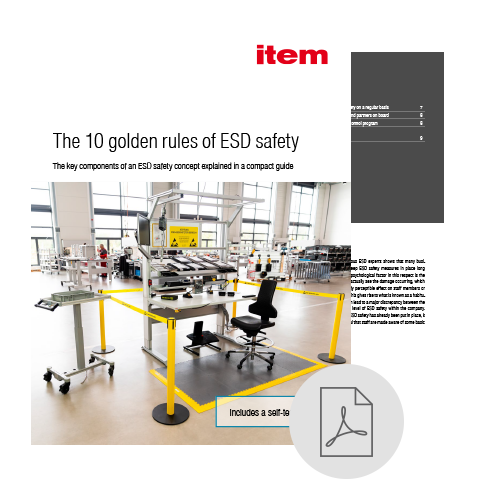

When it comes to ESD safety measures, an electrostatic protected area (EPA) plays a key role. Electrostatic discharge sensitive (ESDS) components and devices must only be unpacked, handled or assembled inside an EPA. This is because only an EPA provides the ideal conditions for preventing ESD – all materials used in this area are electrostatically dissipative and earthed to the same potential. This applies to components, equipment, surfaces and clothing, all of which are used inside a demarcated and clearly designated area. This means electrostatic charges and differences in potential can be avoided in a targeted way. As a basic principle, an EPA can consist of a single workstation, a defined space or even an entire building. All rules applicable to the EPA also apply to the workstations inside it. In other words, an ESD workstation is located inside the EPA and must therefore also comply with the applicable requirements.

Avoiding electrostatic discharges – work benches for ESD protection

When it comes to setting up an ESD workstation, a specially equipped ESD Work Bench with a volume-conductive table top is a fundamental element. If components are handled in a small area of the work bench only, an ESD Table Mat made from conductive material can also be used. Any employee at a work bench of this type should always wear an ESD Wristband for the purposes of personal grounding. Like all protection elements, this wristband must be connected to the earth. To ensure this is achieved, contact is established between the ESD protection elements and the table frame. The table frame itself is connected to a separate earthing line, the protective earth of the power supply or a potential equalisation system. Compliance with the dissipation resistance and surface resistance limits stipulated in standard IEC 61340 is essential for ESD safety. All work and storage surfaces are particularly important in this regard. In addition to satisfying the stipulated maximum resistance, these must also meet a minimum requirement. This ensures potential charges don’t dissipate too quickly and thus cause damage.

The models configured for the Work Bench Configurator include a work bench with comprehensive ESD protection that can be flexibly adapted.

Customers should always insist upon an ESD safety measurement for every new ESD work bench, since this is not always factored in. When it comes to reliable protection, blanket statements or generic certificates are not enough. At item, this measurement is standard – customers receive a special ESD record that shows their ESD work bench has been checked at the ESD measuring points. These points include both standard points – in other words, the ESD table top and storage areas – and specially selected points that have been chosen in consultation with the customer. This ensures a properly designed solution with the correct discharge resistance levels. IEC 61340 also expressly stipulates that regular checks must be carried out on site. The item Work Bench Configurator makes planning ESD work benches a particularly quick and convenient process. The preconfigured models include a work bench with comprehensive ESD protection that can be flexibly adapted.

Protection at the workstation thanks to ESD chairs and other equipment

Products such as chairs for industrial use generally come in a range of qualities and prices. Even when choosing normal chairs for production facilities, workshops or laboratories, it’s wise to opt for high-quality solutions, given how important this equipment is for occupational health. This is even more important when it comes to ESD safety measures, so special ESD Chairs should be used. These can be fitted with additional electrostatically dissipative arm rests, which provide support for the arms, neck and shoulders, as well as ensuring ESD protection. From an ESD safety perspective, the use of office chairs is a significant risk factor – these chairs rarely provide any electrostatic dissipation due to the materials used.

Tools such as screwdrivers, soldering irons and measuring devices that come into direct contact with ESDS components and devices should always be electrostatically dissipative.

Employees who work in an EPA therefore need special ESD chairs. Electrostatically Dissipative Foot Rests also demonstrate that ESD safety and ergonomics can go hand in hand. Similar requirements also apply to other equipment at an ESD workstation. This means that components such as Grab Containers and tool holders – not to mention the tools themselves – need to be electrostatically dissipative if they come within 30 centimetres of an ESDS component or device. Similar rules also apply to shelves or machine enclosures. Tools such as screwdrivers, soldering irons and measuring devices that come into direct contact with ESDS components and devices should always be electrostatically dissipative. It’s also important to integrate the workstation inside the EPA safely into the intralogistics. This involves a whole new chapter of ESD safety measures, whereby accessories such as an ESD Drag Chain or Antistatic Castors for transport trolleys play an important role.

How to properly protect products and employees

Interactive and ideal for beginners – the free learning module from the item Academy will tell you more about electrostatic discharges (ESD) and how to avoid them.

Expand your training now

ESD flooring together with special footwear and lab coats at the ESD workstation

Another feature of a properly designed ESD workstation is appropriate flooring. Special ESD flooring is conductive and connected to the earth at enough points to ensure that electric charges are dissipated. A distinction is made between permanently installed ESD floors and temporary ESD floor coverings. ESD floor coverings take the form of interlocking mats that are laid down in smaller zones, while permanently installed, entirely electrostatically dissipative floors are used in larger areas. DIN EN 61340-5-1 ff. stipulates that a permanently installed floor must comprise several layers, with multiple copper strips ensuring controlled discharge to the earth.

By wearing conductive ESD footwear, you connect your own body to the ESD flooring. This means that electric charges are safely dissipated when you walk.

However, even ESD flooring isn’t much good if staff don’t have any electric contact to the floor. This is linked to the fact that normal shoes often act as insulators. By wearing conductive ESD footwear, you connect your own body to the ESD flooring. This means that electric charges are safely dissipated when you walk. Daily checks must be carried out to ensure that staff members are properly connected to the floor via their footwear. A Personal Grounding Tester (PGT) is used for this purpose. An ESD lab coat also forms part of ESD-safe workwear. Accessories such as footwear and lab coats in an EPA should exhibit a maximum resistance of 35 megaohms to provide reliable protection against ESD.

Appropriate objects and cleaning once an ESD workstation has been set up

The actual setting up of the ESD workstation is not the only crucial factor – employee behaviour is also of vital importance. For example, to prevent ESD, it is crucial that employees do not bring any insulating materials to the workstation. These include objects such as food containers, coffee cups and plastic folders and sleeves. Polystyrene objects should also be avoided. Thorough cleaning of the work area is another must. If dirt and dust accumulate on the workstation surfaces, an ESD chair or the ESD flooring, this will rapidly impair the ESD protection. Particular requirements apply to the cleaning of insulating and transparent materials that are electrostatically dissipative due to their special coatings. If unsuitable cleaning materials are used or excessive pressure is applied, this may damage or completely remove the coating, thereby increasing the likelihood of ESD.

Interested in applications and solutions for ESD safety? Then we have something that’s right up your street! Simply subscribe to the item blog by completing the box at the top right.