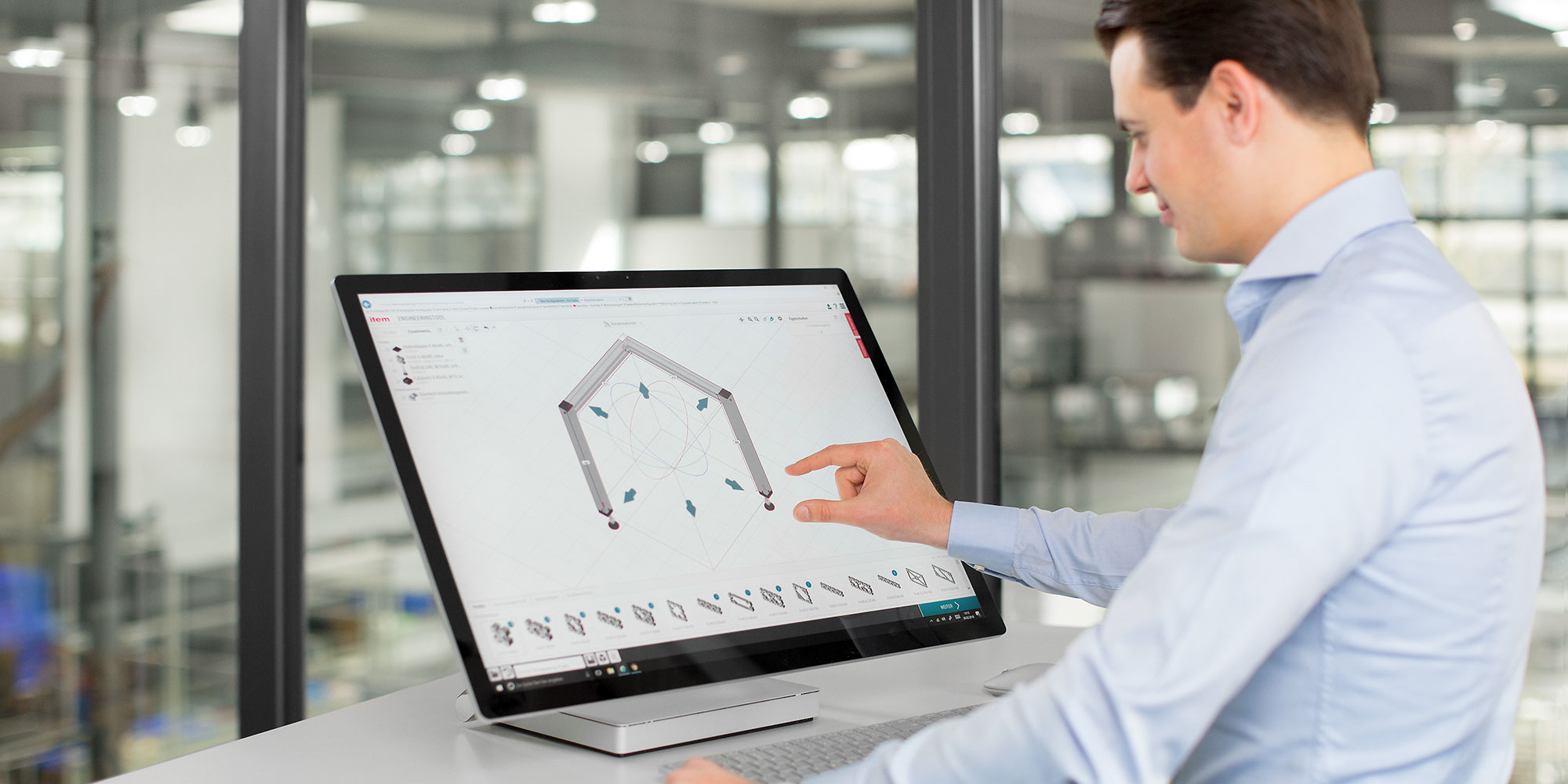

Traditional CAD programs are time-consuming and therefore cost-intensive – the item Engineeringtool can help.

item Engineeringtool users who are designing frames and racks benefit from the speed and user-friendly operation of this unique aluminium profile configurator. All they need is a browser and an end device with internet access. This means they can make a start on their design whenever and wherever they want, based on the MB Building Kit System, the Lean Production Building Kit System and components from the Work Bench System. Rules-based 3D engineering ensures a perfect combination of profiles, Profile Tubes and matching accessories, while the integrated plausibility check prevents components from being placed incorrectly. What’s more, the intelligent aluminium profile configurator automatically adds fasteners, small parts such as screws and T-Slot Nuts, and machining steps such as drilling and thread tapping. From design engineering and the creation of documentation to the order process in the item Online Shop and communication with colleagues – the item Engineeringtool makes all these steps much faster.

How digital is Europe’s mechanical engineering sector?

An enlightening comparison of European countries with numerous recommendations. Take advantage of insights from 295 decision-makers in the engineering field.

Get your copy now!

Engineering software for aluminium profiles – specifically geared to making work easier

When a project involves numerous tasks and several participants, the item Engineeringtool makes life much simpler. There’s no need for design engineers to have a detailed knowledge of item profile technology. The item Engineeringtool acts as a fast, intelligent intermediary, so if users don’t happen to know which product variant is recommended, the online tool can help. Thanks to the integrated variant technology, it’s quick and simple to select the right product variants based on parameters that are easy to understand. The choice can be narrowed down using filters such as design, grooves, product line and material thickness. Based on the data entered by users, the tool calculates which product meets the requirements. Once the appropriate profile has been identified, the item Engineeringtool continues to make life easier by automatically adding the appropriate fasteners in the correct positions, together with the profile machining that is required and the holes that need to be drilled. Moreover, users can position components very easily using drag-and-drop controls in a 3D environment, moving freely with stepless zooming. Thanks to the intelligent automatic processes, this aluminium profile configurator creates realistic and safe designs – and, in the case of standardised engineering work, it is up to 94 percent faster than a traditional CAD program

Thanks to the intelligent automatic processes, standardised engineering work is up to 94 percent faster than with a traditional CAD program for users of the item Engineeringtool.

Caps provide a particularly good example of how the item Engineeringtool makes life easier for design engineers. They previously had to choose the appropriate Cap from over 200 options in the Online Shop. Using the item aluminium profile configurator, on the other hand, they simply need to select the Cap once and drag it onto the profile. A suitable Cap is automatically selected. If various options are possible, the final Cap variant can be configured based on the properties. If floor elements such as swivel or fixed castors are being added, there is no need to select either screws or other fastening elements – the software automatically adds all of these as appropriate, leaving users to focus their full attention on the actual design. What’s more, it’s really simple to select and duplicate components by double-clicking them and using copy and paste. As a result, repeated steps in the design process are exceptionally easy, too, and basic frames are created in next to no time. But what happens if requirements change and the profile lengths or the frame size needs to be adapted? It couldn’t be simpler – just use the mouse to drag and modify them or enter the dimensions directly. Users will get to grips with the software almost instantly, and can also easily obtain special tips and tricks by watching video clips on the item YouTube channel.

Saving further time – thanks to the aluminium profile configurator with automatically generated documentation

Once the engineering process is complete, the documentation step normally takes a similar amount of time. For example, it’s not unusual to spend two hours or more preparing a dimensioned drawing, a parts list and a machining plan. However, the aluminium profile configurator also saves time during this step, as all the documentation is generated automatically with a single click. The item Engineeringtool analyses the design with all the installed components and checks the profile machining and fastening requirements. The project documentation is then generated in no time at all. Users can choose between compact, detailed or complete documentation. The last of these includes the full parts list, information about the machined profiles, an isometric view, a multiview projection with internal and external dimensions, an exploded view and an assembly guide. All in all, this takes design engineers up to 90 percent less time than preparing the documentation manually in a CAD program.

However, it’s not just the work of design engineers that is made easier, but also the process of sharing data with colleagues from other departments and their actual work, too. There are just two requirements – the Projectviewer and the internationally unique CX article number. Every project in the item Engineeringtool that has been placed in the cart has this number. Clicking the link on the relevant documentation’s cover is sufficient to get to the relevant project, which then opens in the Projectviewer. This completely eliminates the kind of compatibility issues that may otherwise occur when sharing CAD files. In addition to being useful for colleagues who are assessing a design and want to discuss it, this easy access also streamlines the quotation process. The direct link to the item Online Shop means registered users can see all the prices. This saves purchasing staff a great deal of time when evaluating an existing design and also when preparing rough costings for future projects.

Animated 3D assembly guide offers direct support during assembly

One innovative function that expressly addresses a typical challenge faced by assembly staff also makes life easier for them. Due to their individual properties, some aluminium profile fasteners need to be fitted in a particular sequence. If staff need help determining the correct assembly sequence, they can refer to a 3D animation. This is possible thanks to the aluminium profile configurator’s 3D assembly guide, so there’s no need for staff to have a detailed knowledge of all the components. The animated 3D assembly guide is also useful when it comes to mentally preparing for the work ahead and also for checking purposes.

Ongoing enhancement of the item Engineeringtool means users are saving ever more time.

This guide is available in the Projectviewer. One particularly practical feature is the QR code on the label of all profiles. Scanning one of these codes on site with a mobile device takes the user straight to the relevant project in the Projectviewer. It’s then sufficient simply to click on the “Assembly guide” option. The ideal assembly sequence is then determined, and the individual steps are shown in an animation, one by one. This is a perfect example of the key benefit for users of the item Engineeringtool – project participants are helped with the very tasks that take them the most time. Ongoing enhancement of the item Engineeringtool means users are also saving ever more time.

Are you interested in digitalisation and what the future holds for mechanical engineering? Then we have something that’s right up your street! Simply subscribe to the item blog by completing the box at the top right.