Day-to-day work is changing as a result of increasing automation.

In many cases, staff members can be in charge of multiple areas and machines at the same time. However, when it comes down to the practicalities of these arrangements, consistency is severely lacking, as human-machine communication (HMC) has not developed uniformly in all quarters. Merely relying on indicator lights or fixed monitors will not satisfy the speed and flexibility requirements of production operations today. In fact, this will lead to machine downtimes and an increased need for coordination. Eager to tackle these very issues, Michael Reutter and Benjamin Schaich founded their start-up aucobo back in 2016. Their software program, which is compatible with all platforms, both improves communication between humans and machinery and enhances coordination among staff. Thanks to its Industry 4.0 concept, the fledgling company has already managed to win over big names such as Audi and Continental.

Digitalisation is a must

From training and in-house processes to business models, there’s no avoiding the digital revolution in mechanical engineering. Our white paper brings you bang up to date.

GET YOUR COPY NOW

Simplifying communication in a whole host of ways

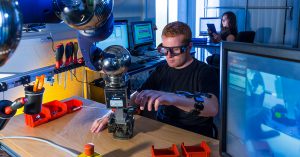

The HMC solutions from aucobo are geared towards analysing machine data and subsequently distributing it among the workforce. “At our company, ‘distribute’ doesn’t mean simply dishing out jobs to people. Instead, employees decide among themselves who should take care of a certain task,” explains Reutter. The company’s solutions also ensure results can be easily recorded. The interfaces responsible for interaction between humans and machinery and within the workforce itself are smart wearables that have been specially designed for industrial use. Although aucobo’s software is compatible with any platform, smartwatches are a particularly ideal option for those working directly at shop-floor level.

Be it a smartwatch, smartphone or tablet – it is vital to always choose the device that best suits the intended user and application scenario.

For example, consider the normal working day of a maintenance engineer or machine operator. Both need their hands free to carry out the numerous tasks they typically encounter. If aucobo’s HMC software were only available on a smartphone, a lot of notifications would go unnoticed. Providing the solution as a wearable device, however, ensures staff can focus on their work undisturbed and still receive discreet notifications from the relevant machine. “Imagine, machine operators had to whip out their smartphones every time they received a notification. It wouldn’t take long for them to lose their patience,” Reutter points out. Logisticians, in contrast, are used to larger screens and usually very fast scanners, so a viable option here would be specially designed smart devices equipped with a laser scanner and a larger display. Be it a smartwatch, smartphone or tablet – it is vital to always choose the device that best suits the intended user and application scenario. After all, staff will only continue using a solution if they believe it offers added value and doesn’t get in the way of their work.

How human-machine communication (HMC) is becoming easier than ever before

The aucobo core serves as the “brain” of the three-tier system developed by aucobo. The workflow editor plays a particularly important role here, allowing users to respond to changed processes by easily and flexibly developing their own apps via drag-and-drop. Employees at shop-floor level haven’t been forgotten about, either. “Let’s imagine that an employee has come up with an idea for an improvement. They can quickly implement it in the system themselves, without having to rely on the IT department,” says Reutter. Indeed, aucobo doesn’t focus exclusively on enhancing human-machine communication. As mentioned above, optimising coordination processes within teams is just as important. For example, a quick scan of a QR code is all it takes to adapt staff roles that have been saved in the system, which encourages employees to keep on organising their workload among themselves.

Staff are notified of their tasks by the software on their mobile devices, with aucobo mobile able to automatically adapt to the relevant hardware thanks to its flexible framework.

The aucobo connector, meanwhile, ensures the aucobo core connects seamlessly with existing systems and machinery. All incoming signals are converted into aucobo-specific language and passed on to the aucobo core, where the data is analysed and the relevant tasks are subsequently distributed among staff based on factors such as availability and skills. Staff are notified of their tasks by the software on their mobile devices, with aucobo mobile able to automatically adapt to the relevant hardware thanks to its flexible framework. The solution also ensures notifications don’t get lost. If the connection drops out, the relevant notifications will be sent as soon as it’s back up and running. An additional function makes sure notifications are passed on to someone else if the originally intended recipient is unavailable.

Special COVID-19 app for safe production

One direct consequence of the COVID-19 pandemic was large-scale production shutdowns across industry. Just like in other areas of the economy, however, creative minds have quickly managed to come up with effective solutions. A perfect example here is the special COVID-19 app from aucobo. “Our customers were naturally among those affected. Apart from the issue of infection, they also wondered how they could stop communication from breaking down despite the fact staff working different shifts had to be kept apart,” says Reutter, commenting on the detailed queries he received. The company was therefore keen to offer its customers rapid support in the form of a customised solution that focuses more on the dialogue between individual employees than the communication between humans and machinery.

The relevant information is anonymised by the COVID-19 app to protect the privacy of staff at all times.

The COVID-19 app takes into account the key aspects of protecting against infection in industrial settings. Indeed, when at work, it can be easy to forget about the recommended minimum distance of 1.5 metres. Users who come closer than this to one another therefore receive a warning message. If someone becomes infected, a “contact diary” ensures the company can trace who the infected person has been in contact with. The relevant information is anonymised to protect the privacy of staff at all times. Last but not least, a photograph function for straightforward documentation and a walkie-talkie option for smartwatches offer ideal solutions for tackling the communication difficulties resulting from changed shift patterns.