How to minimise the risk of electrostatic discharge during transport – discover the benefits and technology of our ESD-safe conveyor belts.

From physics lessons into the production workshop – do you recall the impressive Van de Graaff generators from your school days? Remember how fascinated everyone was by the clearly visible sparks it produced? The constant movement of industrial conveyor belts relative to the drive and glide plate means they build up electrostatic charges in a similar way. This is due to the different materials rubbing against each other and separating again. As these charges build up, they look for a way of equalising themselves. This happens in the form of an electrostatic discharge (ESD). In a classroom setting, such discharges are fascinating. In the production workshop, however, ESD can damage, or even destroy, electronic components. How can the danger of this be reduced? This is where the flexibility of the item Conveyor Belt System comes into play for you. We have expanded it to include ESD-safe flat conveyor belts and timing belts. Combine these with the appropriate item conveyor for all-round ESD-safe transport.

Conveyor belt technology from item

Find out more about the item Conveyor Belt System. This overview will tell you everything you need to know about flat belt conveyors, timing belt conveyors, motors, gearboxes and accessories.

FIND OUT MORE NOW

Importance of ESD protection in production

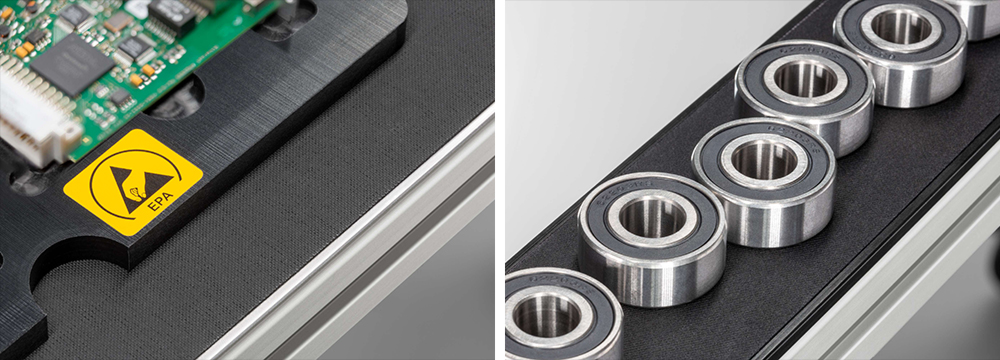

ESD (electrostatic discharge) is generated by friction and contact and separation between different materials. Two differently charged objects can create an uncontrolled equalisation of electrical charges. In the various phases of production, electrostatic charge and discharge can cause microscopic damage to electronic components. This is the invisible danger of ESD. Damage of this kind does not immediately cause products to fail, meaning it is not noticed during final inspection, for example. During operation, however, pre-damaged components can lead to a delayed failure. Other potential consequences include disruption to the supply chain, loss of productivity and additional costs. Many electric components are very sensitive to the rapid and high charges or discharges that occur during ESDs. However, even very low voltages (starting at 30 V) can lead to damage. These are often below the level of human perception, which lies at 3000 V. You should therefore constantly monitor and dissipate such charges. Electrostatic Protected Areas (EPAs) are designed for the direct handling of ESD-sensitive (ESDS) components. Only ESD-safe equipment and materials are used in these areas.

Conveyor belts are prone to natural charging due to how they function. Electrostatic charges of more than 6000 V can rapidly build up.

– Michael Böhm, Managing Director ESD-Akademie GmbH and ESD-Protect GmbH

In production, movement represents a major challenge in terms of ESD protection. Due to the characteristics of their materials, conventional conveyor belts build up static charges. “This charge can be particularly intensive when there is movement on the belt, leading to electrostatic charges of more than 6000 V,” explains Michael Böhm, Managing Director of ESD-Akademie GmbH and ESD-Protect GmbH. However, according to ESD standard IEC (DIN EN) 61340-5-1, the charge in an EPA must not exceed 100 V. A charge of over 100 V can at least pre-damage ESD-sensitive components on a conveyor belt. You should therefore ensure that the charge is not created on the conveyor belts and is dissipated.

ESD-safe conveyor belts from item

An ESD-safe conveyor belt is vital to ensuring smooth, reliable production. As a worksurface for the further processing of electronic components and as a means of transport to an EPA work bench, it is a valuable link in the chain. ESD-safe conveyor belts are constructed in such a way that they prevent and dissipate electrostatic charges effectively. In the item Conveyor Belt System, you will find Flat Conveyor Belt PUR ESD, accumulating for flat belt conveyors and Timing Belt T5 PA, accumulating for timing belt conveyors. Neither product accumulates a charge, even when subjected to friction. The stainless steel plate under the flat conveyor belts and the ESD-safe timing belt guide strips dissipate the charge to the earthing system of the motor. The ESD-safe PUR flat conveyor belts have an especially robust surface that exhibits reduced static friction. They are available in eight widths, from 40 to 400 mm. Thanks to its low-friction surface, the timing belt with T5 tooth shape and steel strands is ideal for accumulation. You can choose between widths of 40 or 80 mm.

You can integrate the timing belt conveyor particularly efficiently for transporting ESD-sensitive components between work benches.

In normal conveyor operations, goods are simply transported from A to B. In accumulating operation, on the other hand, the belt keeps running underneath the accumulated or stopped components at the end of the conveyor section. This could be necessary for carrying out another process step, such as…

- when a part is inserted or installed,

- when a worker assembles or checks something,

- when a camera system carries out an inspection, or

- when it is necessary to separate the components.

You will find the perfect solution for both types of operations in the item Conveyor Belt System. The accumulating conveyors with ESD-safe belts from item are perfect for use in an EPA. The flat belt conveyor has a continuous, unbroken surface, making it ideal for transporting workpieces of various sizes. When it comes to transporting heavy loads, the timing belt conveyor is what you need. What’s more, the central gap on a timing belt conveyor offers space for sensors and stoppers. You can therefore integrate the timing belt conveyor particularly efficiently for transporting ESD-sensitive components between work benches.

Standard-compliant safety assured by ESD audits

To protect ESD-sensitive components, the IEC (DIN EN) 61340-5-1 standard specifies an ESD control program. You should therefore regularly monitor implementation of the ESD protection measures. In this way, you can ensure that your ESD protection complies with the relevant standards. Do this by performing ESD audits. These can either be conducted in-house or by an external service provider. A common reason for failing this kind of audit is the conveyor belt. If you use conveyor belts for transporting electronic components within an EPA, this belt absolutely must be ESD safe.

In an EPA, you must never use a conveyor belt that can accumulate a charge, and is therefore not conductive.

“A conveyor belt should not accumulate a charge of over 100 V – that is the limit specified in the standard. However, in some cases, we measured values of over 3000 V,” says Böhm. ESD containers on the conveyor belt represent a further risk factor. Ensure these containers are transported on a conductive surface. You can only be sure of this by using conductive conveyor belts. “Conveyor belts are very often categorised as particularly critical in ESD audits because they generally do not exhibit ESD-safe characteristics,” says Böhm. The conveyor belts used in an EPA must therefore all be verifiably ESD safe.

Benefits of ESD-safe conveyor belts

The variants of our ESD-safe conveyor belts enable us to ensure one thing – you will find the perfect solution to meet the differing requirements of production environments. The primary aim is to boost production efficiency and minimise the invisible danger of electrostatic discharge. An accompanying test certificate confirms compliance with the defined limits for electrostatic discharge. You can therefore count on the fact that the ESD safety of our conveyor belts has been tested and certified to DIN EN 61340. Another plus point is that the item Conveyor Belt System is available in the free item Engineeringtool. As a result, designing conveyor belts is simpler and faster than ever before.

item Engineeringtool – support for everyone, from beginners to experts

Whether you are looking for basic information about the item Engineeringtool or details of the latest innovations, you will find everything you need here and much more besides, including preconfigured solutions and a direct link to our specialists.

FIND OUT MORE NOW

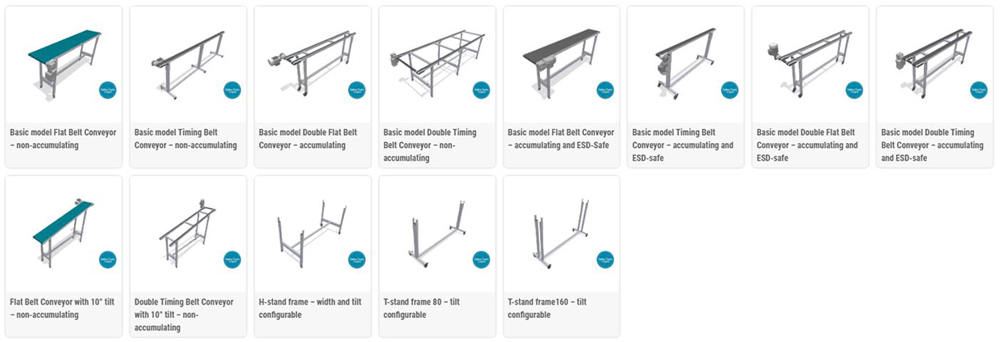

Simple conveyor belt design online

You can use the item Engineeringtool to design conveyor belts directly online. All you need is an end device with internet access and a browser. First, select either a single conveyor (Flat Belt Conveyor or Timing Belt Conveyor) or a double conveyor (Double Flat Belt Conveyor or Double Timing Belt Conveyor) from the item Conveyor Belt System. Next, drag and drop the conveyor belt into a 3D environment and configure it. Then add the drive technology and stand structures. Thanks to the modular system, you can also combine your conveyor belt solutions with other item constructions in the Engineeringtool.

You can also use the item Engineeringtool for variants. If any changes are needed, save the project and adapt the design as desired. What’s more, you also benefit from the typical advantages of this software:

- Free, rules-based design

- Automatically generated project documentation

- Creation and export of CAD data in various formats

- 3D assembly guide with recommended assembly sequence

- Ability to place an order directly in the item Online Shop

To save even more time, you can use our sample solutions. If you do, you have two options – use the sample solution directly, thanks to complete CAD data and parts lists, or take inspiration from the sample applications for your own customised solution.

The conveyor belts and stand structures you order will be delivered preassembled. They will be with you in no time at all. What you see is what you get – thanks to the precise 3D visualisation in the item Engineeringtool, you can see exactly what your finished conveyor belt solution will look like. Moreover, this ESD-safe conveyor belt enables you to protect your components from the invisible danger of ESD. It’s not always the visible spark that does the damage. It is often the invisible dangers of ESD.

Interested in applications and solutions relating to ESD safety? Then we have something that’s right up your street! Simply subscribe to the item blog by completing the box at the top right.