Discover why manual production remains essential for industry.

Although automation is becoming increasingly important, a wide range of products are still made at manual workstations. Special requirements mean certain areas depend on manual work. Especially when it comes to intricate components, manual production is a must. Manual work benches are also utilised for reworking – when manufacturing irregularities need to be corrected, for instance. If your application involves numerous variants, complex products, frequent product rotation or small batches, you should use manual production.

A variety of tools are often required to make individual steps easier and ensure consistent quality. Staff guide and align these tools by hand. Their capabilities represent a key quality factor and depend on their previous knowledge or specific training. This blog post provides three examples of customised manual work benches – for transmission assembly, packing operations and car seat manufacturing. All these projects were carried out by item pluspartners based in Germany – Plan B in Bremen, Irmler in Drebber and BeWA in Simmern – using our profile technology and our ergonomic Work Bench System. The item pluspartner network covers the whole of Germany and includes numerous highly specialised companies. It is the perfect basis for projects in all kinds of areas and on every possible scale.

Manual work benches for the production of transmissions and for packing

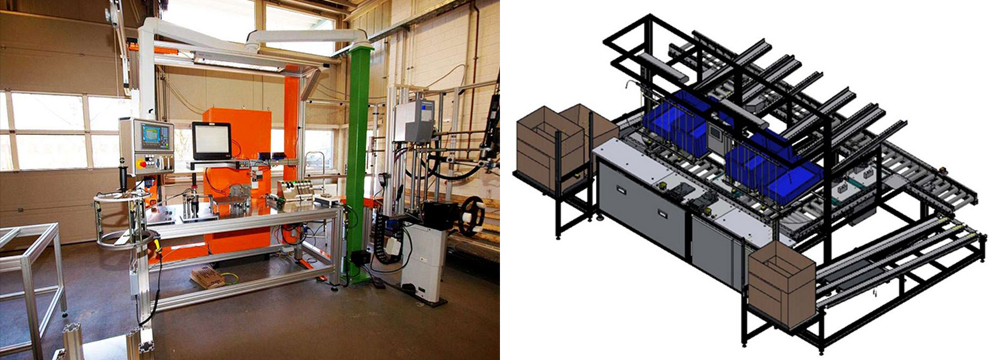

Plan B Automatisierung GmbH has developed manual assembly work benches designed for the small-series production of transmissions. Assembly takes place at three stations – pre-assembly, completion & marriage, and completion & final assembly. Staff at the work benches are responsible for the assembly sequences, process safeguards and quality inspections. They also press-fit components and screw them into place. All press-fit operations take place within a load-displacement window. Work is completely flexible thanks to interchangeable mounts – bushings, plugs and shaft seals can all be pressed into place. Component-specific clamping fixtures have been integrated into these interchangeable mounts. Staff use combined torque-angle handheld screwdrivers with radio transmission functionality for the screw connections.

A pick-by-light system monitors the picking process, taking manual work into the realms of digitalisation.

The manual work benches at BeWa Automatisierung GmbH are used to pack sensitive components. This involves a number of different steps. Components are delivered by a workpiece carrier and removed by staff. A pick-by-light system monitors the picking process, taking manual work into the realms of digitalisation. An eye-catching light indicates which part needs to be removed. Staff press an acknowledge button to confirm they have removed the relevant part. Besides confirming the correct part has been taken, this also notifies the management system of the change to stock levels. Lastly, the packed cartons pass along a roller conveyor to the conveyor belt.

Manual production of premium-quality car seats

We finish with the manual work benches at Irmler GmbH. This company has many years of experience working with the automotive industry. It has a variety of fixtures for the complete assembly of car seats. Assembly takes place on work benches designed and made in-house. All fixtures, benches, machines and testing technology must be free of burr and must not have any sharp edges, as this would immediately damage the upholstery. Absolute cleanliness in production is a further have to ensure no grease is transferred to machines or fixtures.

Are you interested in work bench design in production? Then we have something that’s right up your street! Simply subscribe to the item blog by completing the box at the top right.