Fast assembly, maximum flexibility and a wide range of components: Find out how the item Building Kit System can efficiently enhance your engineering work.

And just like that – the frame is assembled. The fitter smiles in satisfaction and thinks: “Wow, that was easy.” Then one little thing suddenly pops out that needs to be changed. That would be quite the problem with a steel design. But, with the modular item Building Kit System, a solution can be found in no time. This is where the core idea of our aluminium profile technology really shines – using aluminium instead of steel and screws instead of welds. In 1980, item founders Gerrit Pies and Wolfgang Rixen created the very first aluminium profile with inward-sloping groove flanks and screwed connections. In doing so, they completely revolutionised factory equipment and mechanical engineering. To this day, countless solutions are still built on the basis of our modular principle, ranging from simple frames to equipment for digital factories. With the versatile aluminium profile technology from item, you can easily make your ideas a reality. Want to find out more about the possibilities? Then get to know our aluminium profile types and aluminium profile fasteners now.

The benefits of aluminium profile technology at a glance

The benefits of our aluminium profiles start with the material. Aluminium is significantly lighter than steel. This makes it easier to transport and work with on site. At the same time, aluminium is extremely strong and offers maximum stability. Using aluminium profiles only requires three steps – sawing, screwing and assembling. One fitter can handle all that on their own. Forget extra training or additional equipment. With steel, there are up to eight steps – sawing, machining, fixing, welding, cleaning, priming, painting and finishing. All those steps add up, costing you time and money. Another disadvantage is that steel structures cannot be subsequently modified. An investment in item aluminium profile technology is an investment in the future – adapt a design at any time. Or dismantle it and use the materials for your next project.

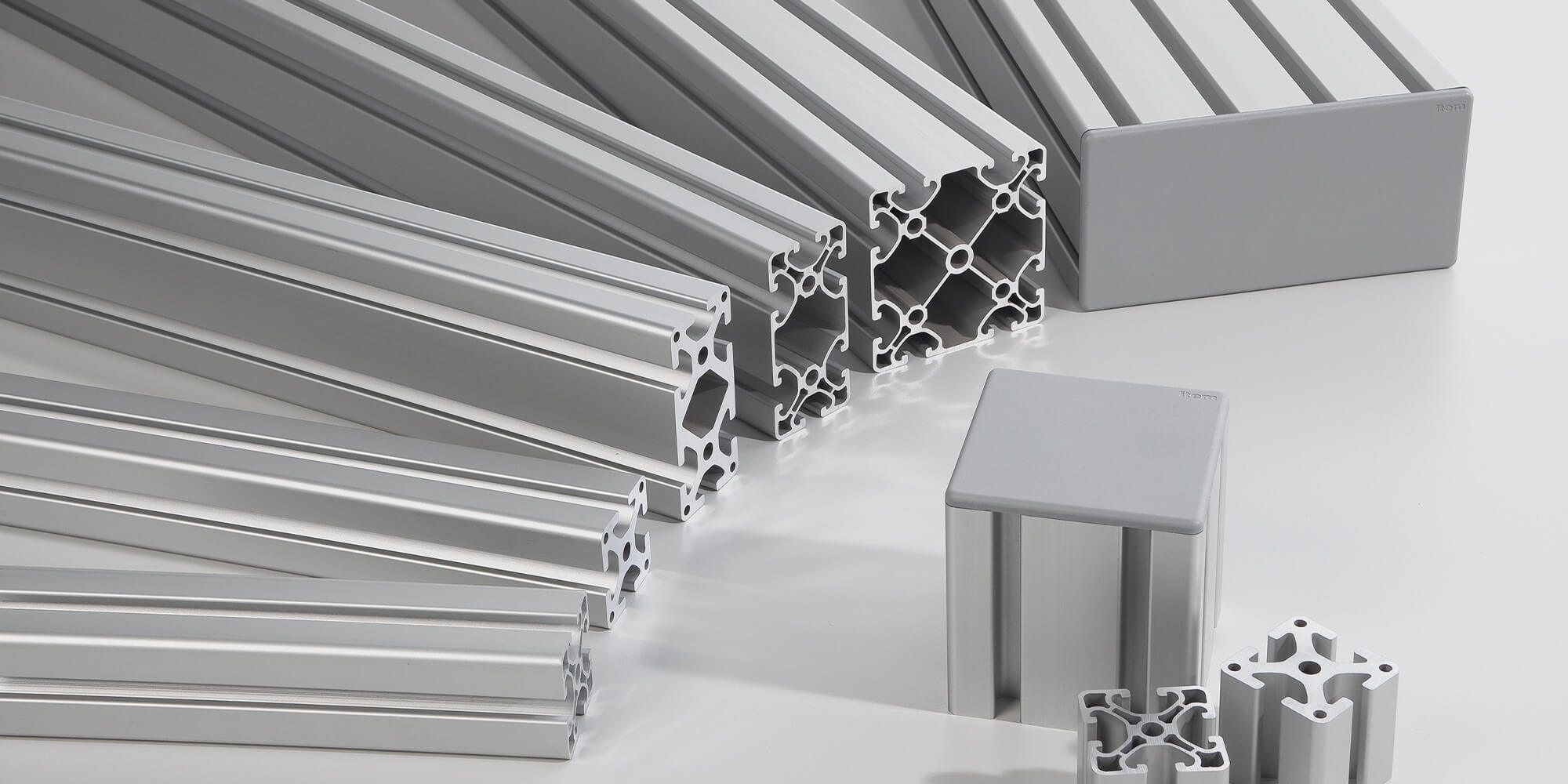

There are currently over 4500 components available in the item Building Kit System. They are all modular and compatible with each other.

With aluminium profile technology, it’s not just the profiles that have to fit together. It all comes down to the perfect interplay between quality, flexibility and customer service. Our high standards deliver quality that you can rely on. All products undergo thorough testing at the prototype stage. Thanks to our promise of continuous availability, you can rest assured that everything will fit together even decades later. You can continue using and ordering components you first obtained in the dim and distant past. And you can even combine these with current products and future releases. There are currently over 4500 products available in the item Building Kit System. They are all modular and compatible with each another, while our award-winning focus on timeless, functional design ensures a fully cohesive look. As passionate tinkerers, we are always hunting for new solutions. In addition to that, we also offer outstanding delivery reliability. No matter where you are in Germany, you will receive all standard products within 48 hours. Thanks to forward-looking planning, we manage to keep this promise even in times of aluminium shortages.

Handy overview of item profile lines

Our construction profiles are divided into different aluminium profile types. Lines 5, 6, 8, 10 and 12 have all been developed for different applications. Individual lines differ in terms of their modular dimensions, groove dimensions and bore diameter. There are three variants: Standard, Light and Economy. “Standard” is the normal version. “Light” denotes profiles that are light in weight. “Economy” stands for a material-optimized design. Important: Not every aluminium profile is available in all variants. We developed Profile Tube System D30 for lean factory equipment engineering. Its Tubes and Profile Tubes are significantly lighter than steel tubes and permanently stable. The basic diameter of 30 mm corresponds to the modular dimension of Line 6. Another special profile type is Profile KH, which is made of a sustainable composite material that weighs less than steel. Profile KH also boasts exceptional electromagnetic compatibility.

Line 5 – the most compact item profiles

- Ideal for all types of weight-optimised constructions

- Compact dimensions for flexible, stable and intricate applications

- Perfect for compact fixtures as well as covers and handling systems

- Low material usage safeguards resources

- Available with open and closed grooves

- Closed grooves prevent dirt accumulation

Line 6 – low material consumption for high performance

- Weight-optimised for lean, robust constructions

- High carrying capacity despite low dead weight

- Ideal for functional and attractive display cases, tables and cover hoods

- Easily adapt material usage to the task

- Available with open and closed grooves

Virtual factory tour

Click your way through the modular world of item: Discover various different ways that item products can be used in our animated, interactive tour. Product information and links to practical downloads are also included!

Line 8 – the all-rounder of profiles

- Universal, robust and durable

- Ideal for machines and systems of all sizes in mechanical engineering

- The most commonly used item aluminium profile worldwide

- Tensile load up to 5000 N

- Available with open and closed grooves

- Line X uses the profile groove from Line 8

Line 10: Aluminium profiles with increased load-carrying capacity

- Increased load-carrying capacity for robust constructions

- Strong groove flanks increase load-carrying capacity

- Enhanced reliability against pre-tension losses

- Tensile loading up to 7000 N per screw connection

- Weight-optimised Profiles 10 E for areas exposed to lower loads

- Caps and cover profiles made of plastic for closing the end faces and grooved sides of the profiles

Line 12 – strongest profile series in the item Building Kit System

- For stable, heavy-duty frame structures

- Strongest profile series in the item Building Kit System

- Tensile loading up to 10,000 N per screw connection

- Exceptional reliability against pre-tension losses

- Profiles 12 light can easily be used in areas of the base frame that are subject to lower stresses

Line X – smooth transitions between aluminium profiles

- Ideal for machines and systems with high cleanliness requirements

- Precise outer edges with minimal radius

- Dirt and deposits stand no chance

- Available with open and closed grooves

- Variants with a closed groove are ideal for use in cleanrooms

Aluminium profile fasteners and their individual strengths

As you’ve just seen, the range of uses for aluminium profiles is immense. However, it is not just the profile range that has to be so versatile. The same applies to the associated fastening technology. Generally speaking, aluminium profile fasteners have two tasks – securely connecting profiles to one another and stabilising the construction. Using item fasteners, you ensure that profiles are held securely in place no matter the installation scenario. The load specifications for our fasteners are based on rigorous tests and numerous safety factors. Unpredictable factors such as vibrations or temperature fluctuations are also taken into account.

As you’d expect from a team of true specialists, all fasteners have their own unique attributes.

Thanks to our numerous fastener types, there is a suitable solution for every task. As you’d expect from a team of true specialists, all fasteners have their own unique attributes. The Universal-Fastening Set offers exceptional flexibility. However, it does require some profile machining. This is not the case for the Automatic-Fastening Set, which makes assembly quicker and easier. This is a real bonus, especially for standard designs with multiple variants. Discover some typical fasteners now. You can find an overview of all aluminium profile fasteners in the item Online Shop.

Standard-Fastening Set – the all-rounder

- Suitable for permanent, stationary connections between aluminium profiles

- Outstanding resistance to displacement and torsion

- Minimal machining and maximum cost-effectiveness

- One-sided variant for the practical insertion of panels into grooves without additional machining

- Available for Lines 5 6, 8, 10 and 12

Universal-Fastening Set: Low assembly requirements

- Perfect for retrofitting onto aluminium structures

- High load-carrying capacity and flexibility, easily adjustable

- Only requires two stepped bores in the aluminium profile that is being added (profile B)

- Easy assembly – simply position the pre-assembled fasteners in the groove of profile A

- Then push the fasteners into the stepped bores in profile B and tighten

- The newly attached profile B can then be moved along the groove

- Available for Lines 5, 6, 8, 10 and 12

Automatic-Fastening Set – universal and friction-based

- Ideal for adjustable and robust right-angle profile connections

- Exceptionally fast and time-saving assembly

- No profile machining required

- Suitable for retrofitting onto aluminium structures

- Just screw the fasteners directly into the groove of profile A, at the end face

- Then insert T-Slot Nuts into the groove of profile B and screw the aluminium profile fasteners in profile A into the T-Slot Nuts.

Fastener D30 – strong support for lean factory equipment

- Mechanically locked connection with the contour of a Profile Tube D30 or Profile 6 D30.

- Permanent hold without creep

- Connection holds immediately after tightening

- Easy enough for just one person to assemble

- Up to four fasteners can be mounted onto a Profile Tube at intersecting points

- ESD-safe contact established automatically

- Fastener D30 arrives pre-assembled, thereby reducing assembly time

More interesting facts about aluminium profiles

Want to find out more about item aluminium profile technology? Whether it’s online training in the item Academy, some basic information, technical details in the item Online Shop or other blog posts – we’re more than happy to share our knowledge with you. All you need to access the online training courses of the item Academy is an item user account. Register for free here. Find out more now:

- Online training: “Introduction to profile technology”

- Online training: “Introduction to fastening technology”

- Online training: “Selecting profiles and carrying out calculations”

- Overview of the item Building Kit System

- Profile technology in the item Online Shop

- Blog post: “Aluminium profile types –an overview of the differences”

- Blog post: “Overview of aluminium profile fasteners –a solution for every application”

- Blog post: “The sign of a high-quality fastener”

- Blog post: “Aluminium profiles in specialist mechanical engineering – ideas and benefits”

Want to keep up to date with everything that’s going on in the world of item? Simply subscribe to the item blog by completing the box at the top right.