Whether it’s due to the pandemic, geopolitical differences or now a war in the heart of Europe, companies around the world are struggling with supply shortages. So how exactly can businesses maintain their supply capability under the current pressures?

Going, going, gone – in 2022, the scarcity of raw materials has been further aggravated by the current global situation, which is having an impact on numerous sectors. For instance, the demand for copper, palladium, nickel, neon and aluminium is steadily increasing. However, supply is struggling to keep up. There are many reasons why the shortage of raw materials has become so drastic, as a brief look at the aluminium shortage shows. It also becomes clear just how crucial it is to lay the groundwork for flexible responses to times of crisis through long-term planning.

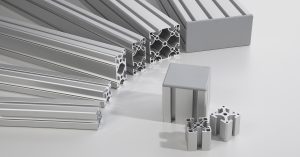

Aluminium shortage: So, what does it all come down to?

There are various reasons for the growing aluminium shortage. It’s always wise to take global contexts and differences into account, perhaps best exemplified by the dependency on China. After the COVID-19 pandemic led to logistical problems and cost increases, some regions seem to have at least partially overcome these issues. However, a lockdown was imposed in the southern Chinese city of Baise in January 2022. Since Baise is the “aluminium capital” of China, the lockdown has had a considerable impact. There was a similar situation in November 2021, when China’s magnesium production was reduced for environmental reasons. With a 90 percent market share, China is the world’s largest producer of magnesium, which is found in many aluminium alloys. Political problems between the EU and China had previously put a strain on the aluminium market.

Russian aluminium production has not been affected, but due to the sanctions, exports are becoming significantly more difficult, and aluminium is becoming increasingly scarce.

The effects of the war in Ukraine on the supply situation are particularly acute at the moment. According to the EU’s “Raw Material Information System” (2019), Russia, with a market share of 6 percent, is the world’s second-largest producer of refined aluminium after China (56 percent). Recently, the EU procured 17 percent of the aluminium it needed from Russia. In late February 2022, the price of aluminium was already at an all-time high. Russian aluminium production has not been affected, but due to the sanctions, exports are becoming significantly more difficult, and aluminium is becoming increasingly scarce – so much so that a complete halt in supply cannot be ruled out. What’s more, aluminium production in other countries is also becoming more expensive due to rising gas prices. In a nutshell, the industry in 2022 is marked by an increasing shortage of raw materials and soaring energy prices. With availability continuously dropping across the board, prices are rising sharply.

How item is guaranteeing security of supply even in times of crisis

“Crises are unpredictable by nature. None of our aluminium suppliers are based in Russia or Ukraine, so we’re not directly impacted by the issues facing the supply chain. But there are still ramifications,” says Thomas Neller, the item Managing Director responsible for purchasing. Regular price increases and the steady rise in energy costs inevitably have consequences. Generally speaking, item relies on long-term planning and partnerships with aluminium suppliers throughout Europe, extensive warehouse stocks and forward-looking orders. item takes a similar approach when it comes to other materials, too, creating the ideal conditions so as to be prepared for as many market influences as possible. All of this serves one goal – guaranteeing security of supply for its own customers.

Guaranteed supply availability is what sets item apart.

The item Management Board responded immediately to these special circumstances by signing contracts with suppliers to ensure availability, even in these times of sky-rocketing prices, thus securing both the raw materials and the suppliers’ resource and production capacities. “What sets us apart is that we are always able to maintain supply availability. Even now, we are still able to deliver our standard articles anywhere in Germany within 48 hours,” explains Neller. This gives item customers absolute planning certainty, even in these times of acute aluminium shortages. In terms of pure function, the advantages of the modular building kit system truly shine here, too. After all, the system can offer multiple potential solutions to any challenge.

Genuine partnership and a worldwide supply network

Reliability and partnership have always been top priorities for item. This applies both externally, when dealing with customers and suppliers, and internally. With materials planning, sales and production being so closely coordinated, item is able to respond quickly to new developments, as Thomas Neller points out: “The crises of the last few years have also made us stronger as a company. We have a software solution that makes our day-to-day business easier, but true intelligence can only come about when people themselves network. We always find a solution for our customers.” Long-term investments for the future make it possible to react flexibly to unforeseeable events. For instance, German sub-suppliers were affected by the floods in 2021. Thanks to its multi-sourcing strategies, item was able to compensate for these shortfalls through other sources.

Global Supply Network in action: item foreign subsidiaries can order materials from the European headquarters in Solingen, and even directly from European suppliers or item subsidiaries.

A broad international positioning always pays off, as the item “Global Supply Network” clearly illustrates. For example, the supply route for the item sales subsidiary in Asia used to be covered by train through Russia. However, thanks to the flexibility of its own supply network, item was able to switch to cargo ships at short notice. Not only that, but there are numerous procurement options available to international partners. At the same time, the company’s focus remains firmly on the future: “For example, if the current crises in the automotive industry come to an end, production will probably be ramped up, and demand for aluminium in this sector will increase again. Thanks to the system we have in place, we are well prepared for this,” says Neller.

Raw material and aluminium shortages in 2022 – approaches for ensuring reliable supply

High availability and reliability are crucial if a business is to be successful in times like these. So how can companies keep the commitments they make to their customers, safeguard maximum delivery quotas and avoid delivery bottlenecks?

1. Adopt a predictive and strategic approach to planning raw material requirements

If a company is to optimise its processes along the supply chain, then it needs to plan its resources and capacities on a predictive basis. “Top-class teamwork in product group and supplier management and carefully thought-through sourcing strategies are crucial when trying to maximise security of supply,” says Thomas Neller.

At item, material requirements are planned for an entire year and on a rolling basis. A central aspect of this approach is internal coordination involving all key account managers and sales managers. Thanks to the company’s structures, operational and strategic elements of the business can be closely intermeshed. The situation on the market is continuously analysed and any developments are dealt with directly. Through this approach, item is laying the groundwork for sustainable procurement.

Active management and suitable planning methods

item adopts a collective, interdepartmental approach to developing sophisticated strategies for achieving its corporate goals. Under this approach, sales and operations planning is a useful tool for making sure market needs can be met cost-effectively. It provides an early warning whenever developments in terms of stock levels, capacities and personnel resources start to stray from the annual plan. Managers can therefore take action in good time.

To optimise stock levels on an ongoing basis, item links its CRM system with an intelligent forecasting tool. This involves operations research. Mathematical processes help ensure the right decisions are made in business planning.

Precise sales forecasts thanks to intelligent software

Special software takes into account historical sales and uses mathematical algorithms to calculate optimum demand and compile precise sales forecasts. This means stock levels can be dynamically adjusted and flexibly managed.

The forecasts are updated every day. Unusual sales volumes are identified quickly and schedulers can take immediate action. “Making sure forecasts are accurate is the key to success,” says Neller. “Combined with the skills of our staff and information from our suppliers, the tool works like a kind of early warning system.”

Simulations can also be carried out quickly and easily, enabling users to check how availability and stock levels will be affected if, for example, a supplier drops out of the picture or a particular article can no longer be delivered. The tool then offers recommendations that are always geared toward safeguarding availability.

Optimised warehouse stock at all times

The demand calculated at the beginning of the year is continuously evaluated and adjusted. This means the groundwork can be laid at an early stage and the relevant quantities of material ordered. By contrast, short-term planning forces companies to buy raw materials at the latest prices.

Optimised warehouse stocks safeguard the high availability of item products – for the entire year. Fluctuations in stock levels from one year to the next are also taken into account. Moreover, item does not reduce stock levels at the end of the year only to increase them again in the first quarter of the following year.

An important cornerstone of efforts to safeguard supplies of raw materials involves maintaining close and trusting partnerships with suppliers.

2. The importance of supplier relationships

The central item warehouse in Solingen has enjoyed a steady inflow of materials from long-standing suppliers across the whole of Europe for a great many years. “Some of our contractual relationships have been in place for over 30 years,” states Neller. “Our procurement strategies are based on multiple sources. We have as many as ten suppliers in the aluminium sector to fall back on, which means we are not tied to individual suppliers or pricing conditions.” Some of the suppliers take care of basic requirements while others are brought on board when demand peaks.

Thanks to the long-standing nature of our partnerships with these suppliers, we have especially trusting relationships and gain an in-depth insight into what is happening on the market. We share information proactively and intensively on a regular basis. item also benefits from “economies of scale” and can always get hold of a certain amount of aluminium profiles. Supplier agreements that run for terms adapted to current market conditions ensure supplies are continuously replenished at prices in line with the market.

3. Looking ahead

Where is the aluminium sector headed? What are competitors doing differently? How can staff be integrated into the company even more closely and given the best possible support? Companies do well to ask themselves questions like these and constantly re-evaluate their internal processes. Open communication, flexibility and a constant readiness to continue developing – these are the foundations for a successful future. “In the past, procurement was little more than an office that placed orders, but now we are integral to the supply chain. So what about the future?” asks Neller. “It is hugely important – both now and in the future – to be open to new things.”

What it all comes down to – always being able to deliver

How can companies maintain their delivery reliability – despite the current scarcity of raw materials – and prevent supply bottlenecks? By adopting long-term, resilient and predictive planning. If annual planning is complemented by rolling projections, companies can act with more flexibility and modify demand dynamically. However, optimum planning is not enough on its own. Achieving exceptional delivery quotas requires sophisticated strategies, special software support, dependable partners and forward-looking management. That is how item keeps its delivery promises and manages to supply aluminium profiles that are ordered in Germany within 48 hours.

If you would like to know more about all the latest from the world of item, simply subscribe to the item blog by completing the box at the top right.