What kind of requirements will building kit systems need to meet in the future and how does linear technology fit in?

In this interview with German engineering portal “Konstruktionspraxis”, Oliver Teckenberg, product manager for mechanical engineering and automation at item, answers this question and more.

Mr. Teckenberg, what are the current trends in mechanical and plant engineering?

Customers are finding it increasingly important to have not just a comprehensive building kit system, but also access to ready-made solutions for their fields of activity. Solutions like these significantly reduce their design and engineering outlay and mean they can plan ahead with a great deal more certainty. A comprehensive building kit system also allows users to combine solutions as necessary and extend them to create a functional plant. Extensive sensor and actuator systems can also be integrated into the plant in line with the Industry 4.0 concept.

Building kit systems and the principle on which they are based are on trend. How does that affect your research and development work?

We offer our customers one of the most extensive building kit systems available for mechanical engineering. Besides continuing to develop this building kit system, we are also working in parallel on coordinated solutions that are based on existing components and designed for a range of product areas. For example, we exhibited 25 new solutions for ready-to-install Linear Units at last year’s Motek. It was important that these should be fully compatible with the MB Building Kit System and other solutions such as enclosures and guard systems for production and machine enclosures.

Form and flexibility are crucial considerations when working on a new development, but do materials have a role to play, too?

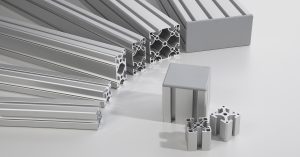

Yes. After all, industrial production is becoming much more automated and short cycle times are hugely important if processes are to be cost-effective. This means that lightweight materials should be used that enable highly dynamic movements while keeping energy usage to a minimum and thus supporting a high standard of overall energy efficiency. item uses a lot of aluminium, which is low in density but high in strength. What’s more, the materials we use are RoHS-compliant and in line with the Europe-wide REACH Directive.

Do you think linear slides will start to appear in new applications in the near future?

The linear units of the future will deliver high output in the tightest of spaces. That is a general goal. However, they won’t be confined to industrial applications in the future. I believe we’ll start to come across more and more of them in our day-to-day lives. One current example would be the pharmacies that use linear units in plain view of customers as an automated means of supplying medicines in a very compact space. Those huge pharmacy cabinets are a thing of the past now. Applications like these, where the linear units can be seen by end customers, bring new requirements. The linear units need to be quiet and satisfy high design specifications.

Does item already offer linear slides that are suitable for applications such as these, for example, quiet-running models?

item Linear Units are based on a range of drive concepts combined with roller guides. Roller guides offer a long service life and are very smooth running. Encapsulated Linear Units with specially developed timing belts, such as our Linear Unit KLE, help to keep noise to a minimum. Design is also a big priority at item. In fact, Linear Unit KLE won the reddot design award in 2008 for its outstanding design.