If you’ve ever wondered about all the wonderful things that can be created with item, you’ll find answers to inspire you in our new online tour.

item components are used to create customised solutions in a whole host of different sectors and industries. This versatility all comes down to a tried-and-tested building kit system approach that has been successfully applied for decades, more than 4500 components with end-to-end compatibility, and a continuously expanding product portfolio. You can now take an interactive online tour to find out about the wide variety of ways you can use item products in your company. This tour, which follows a component on its journey through a perfect imaginary factory, is fun and informative in equal measure. What’s more, additional information, images, videos and download links are available at the different stops on the tour.

The component starts its journey in goods receipt, where it is unpacked for picking on Tables, Economy. These material-optimised models offer stability, flexibility and an introduction to the world of ergonomics, making them ideal for tasks of this kind. The basic models, which are based on either Line 8 or the Lean Production Building Kit System, can be expanded with uprights and overhangs to suit your needs. An item Installation Column in goods receipt also ensures that staff always have access to the latest data. A special variant of the item Installation Column for media supply has been developed.

Virtual factory tour

Delve into the modular world of item. In our animated and interactive tour, you will find out about possible applications for item products, based on lots of examples. Product information and links to practical downloads are also included!

TRY IT OUT NOW

Solutions for material flow, organisation at the work bench and goods transport

After these first steps, the component is forwarded via a FIFO rack and then stored on a work-in-process basis. The Lean Production Building Kit System, which has been specially developed to meet the requirements of lean production, is used here, too. Thanks to the flexibility of the modular Profile Tube System D30, constructions can be perfectly adapted to new processes, meaning that in-house material flow can be continuously optimised. The “one-screwdriver principle” ensures easy handling and efficient assembly directly at the site where the construction is needed – all you need for any 90-degree connection is one person with one tool.

Regardless of whether for automated guided vehicles (AGVs) or tugger trains, the modular item profile technology can be utilised to build customised constructions that are both flexible and lightweight.

Shortly afterward, the component is inspected as part of a random sample quality control process. At the work bench used for this purpose, the item toolpanel® System comes into its own. Components from the hook and holder range are simply fastened to the 19 system grooves of the groove plate profile. This provides the perfect basis for arranging tools and materials in an organised, space-saving and ergonomic way. The component is then transported to manual production. Regardless of whether automated guided vehicles (AGVs) or tugger trains are used for this purpose, the modular item profile technology can be utilised to build frames and superstructures that are both flexible and lightweight. Whether it’s a case of mobile robotics or other areas of material flow optimisation, item really gets things moving in production!

Work ergonomically – and automate innovatively

In manual production, ergonomic work benches are ready and waiting. What’s more, the item Work Bench System means they can be individually adjusted. For example, stepless height adjustment for work benches and chairs allows each employee to precisely adapt their workstation as their height requires. Multi-axis pivot arms and ergonomic parts containers mean that materials and tools can be positioned to suit each employee’s personal handling area. If the component is ESD-sensitive, it is taken to the electrostatic protected area (EPA). After all, the item Work Bench System is also ideally equipped for ESD safety – products such as ESD work benches with a special table top, ESD chairs and appropriate parts containers provide reliable protection against uncontrolled electrostatic discharge (ESD).

When components need to be lifted over intralogistics routes, the combination of Karakuri/LCA and conventional linear technology (hybrid Karakuri/LCA) is ideal.

All other components are transported on in a spectacular way. This is where Karakuri/LCA (= low-cost automation) comes into play. Even though this alternative automation method generally relies solely on spring force, gravity and lever principles, an exceptional case can be seen during the virtual tour. That’s because, when components need to be lifted over intralogistics routes, the combination of Karakuri/LCA and conventional linear technology (hybrid Karakuri/LCA) is ideal. One example of this is a Karakuri/LCA bridge, which is used to move materials in a way that causes absolutely no disruption to transport activities taking place at ground level.

Whether in the world of robotics or cleanroom solutions, modularity is all-important

As the component continues on its journey, it’s all just as impressive. It’s now time for the range extender to take centre stage. This application is a perfect example of ways in which item product ranges can be combined. At the heart of the application is a collaborative robot (cobot) on a linear axis. This linear axis runs parallel to a six-metre-long flat belt conveyor from the item Conveyor Belt System. Thanks to this set-up, the cobot has a seventh axis, which gives it a special level of flexibility for the packaging process. After this structure comes a whole series of machine cabins, where the packaging process is finished off. The component is then deposited in another FIFO rack and subsequently picked for an order in outgoing goods. Here again, the Tables, Economy and an item Installation Column play an invaluable role. In the background, you can see a product line with which the component has no direct contact – stairways and platforms. The Stairway/Platform System is the perfect solution for gaining access to hard-to-reach areas of production facilities.

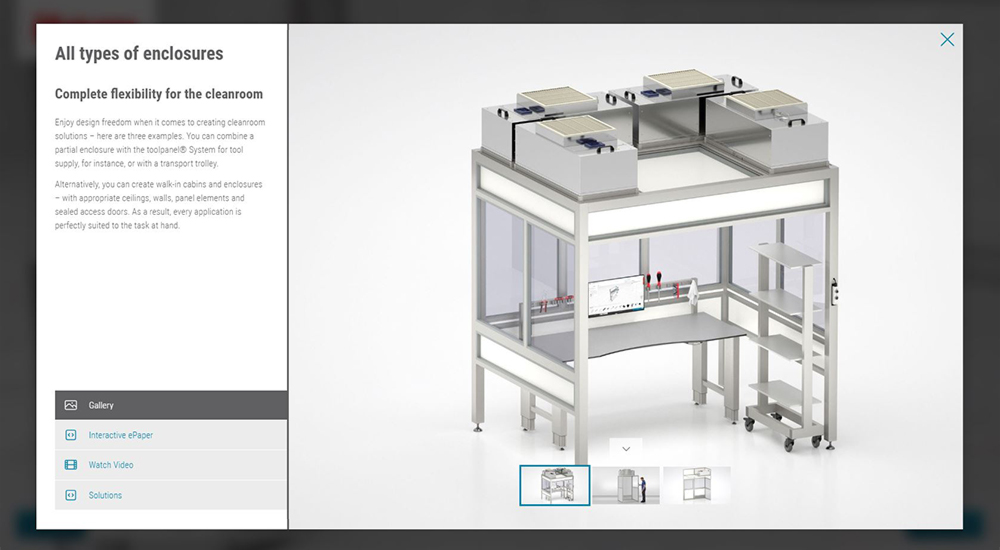

Several filter fan units can be integrated into the ceiling of a partial cleanroom enclosure for a constant displacement flow of clean air.

Quality assurance is next on the tour, featuring a partial cleanroom enclosure as an example. Several filter fan units can be integrated into the ceiling of this cleanroom production workstation to create a constant displacement flow of clean air through the entire area. At the end of the factory tour, we see a work step that actually takes place right at the start. Many of the applications shown are created with the help of the free item online tools. Solutions with profiles or panel elements are designed online using the item Engineeringtool®. When it comes to planning normal assembly work benches or ESD work benches, the item Work Bench Configurator can save you a great deal of time. What’s more, item software makes it easier than ever before to define machining steps. Thanks to the item Machiningtool, the time-consuming, laborious tasks of defining machining steps and preparing technical drawings are now a thing of the past. Curious? Your virtual tour of the factory is just a single click away!

Want to keep up to date with everything that’s going on in the world of item? Simply subscribe to the item blog by completing the box at the top right.