From reliable processes in cleanrooms and intelligent power transmission to additional options in online engineering – the latest product releases from item for autumn 2022 are once again centred around the use of innovation to take winning concepts to the next level.

Based firmly on the building kit system philosophy, the item product range is constantly growing to cover new areas and introduce improvements. At the same time, end-to-end modularity means everything fits together perfectly. For example, the aluminium profiles of Lines X and XMS are ideal for use in cleanroom solutions and, this autumn, there are new products for precisely this application area – Fixing System X 8 for fastening panels in place and Filter Fan Unit 1200×600. The lean production philosophy’s principle of continuous improvement also extends to our online tools, with the addition of panel elements to the item Engineeringtool representing a particularly practical enhancement.

All the new products at a glance

Every innovation in one e-paper! Discover all the new product developments and explore additional information such as interactive graphics in the new products catalogue for autumn 2022.

FIND OUT MORE NOW

Modular door solution that is light in weight and customisable

New Access Door 8 features an all-round rebate. Frame Profiles and the automatic Drop-Down Seal combine to create a seal on every side of the door. While the Frame Profile ensures the Access Door can be shut with a dust-tight closure, the Drop-Down Seal creates a dependable seal with the floor. Thanks to its low weight, the aluminium Door Profile ensures that even large doors can be opened and closed with ease. Although all components are available separately, the solution can also be ordered as a ready-to-install Access Door in standard dimensions or with a custom configuration. Thanks to an online configuration assistant, a custom solution can be put together in next to no time. Height, width, positioning of the cross profile, panel infill and height of the door handle – everything can be specified in just a few clicks, without having to worry about the finer details.

Customised and dependable – clean production with item

Modular solutions for dependability in clean production. When using Fixing System X 8 and the Filter Fan Unit (FFU) combined with HEPA Filter H14, you can easily build customised, fully enclosed cleanroom environments (mini environments). These additions to the item Building Kit System enable users to build cleanroom solutions in different dimensions. Thanks to their smooth, unbroken surfaces, minimal edge radii and integral cable routing, the aluminium profiles of Lines X and XMS are perfect for clean, modular solutions to be used in cleanrooms. The new products for cleanroom applications give users maximum flexibility with only some additional components. That means custom cleanroom solutions can be created in the perfect dimensions – for use in the optics, electronics, automotive, semiconductor, medical and plastic injection moulding sectors. Furthermore, the free item Academy offers online training modules that provide an introduction to cleanroom technology and cover the fundamentals of ISO 14644.

Modular Fixing System X 8 boasts flush joins that are easy to clean.

Fixing System X 8 is the ideal basis for building walls and ceilings in clean production environments. This modular panel-fixing system boasts flush joins that are easy to clean. That means it can be used anywhere where certain areas need to be cleanly closed off from the surrounding environment. Three different wall constructions can be created – single skin, double skin, or a sandwich design using new Compound Material HPL 36 mm as a full-size infill. Panels are held in place on all sides between the Line X or XMS profiles, and without having to be machined. However, there is even more to Fixing System X 8. For example, when combined with Perforated Sheet 3mm, it can be used to create ventilation grilles or working surfaces for cleanroom environments.

The perfect solution for a working and process environment

Thanks to its strong holding force, Fixing System X 8 can also be used to support solid panels or the plug-&-play Filter Fan Unit 1200×600 (FFU). The latter uses Pre-Filter M5 and HEPA Filter H14 to remove 99.995 percent of all particles from the ambient air. This filter action has been tested to EN 2822. The unit’s integrated centrifugal fan produces a laminar displacement flow with a nominal air flow of 997 m³/h. When combined with Fixing System X 8, the FFU can be easily installed into either a ceiling construction or frame. The gasket on the HEPA Filter ensures a dust-tight and airtight seal with the ceiling.

If lights or table columns are to be switched on and off together with the FFU, FlowBox InstallationKit 230V is the ideal solution.

The FFU StarterKit ensures users can connect up their Filter Fan Unit 1200×600 rapidly and get it into use straight away. It contains all the cables and operating elements needed to commission the FFU and control it with a potentiometer. If lights or table columns are to be switched on and off together with the FFU, FlowBox InstallationKit 230V – which additionally contains a switchable multi-socket power strip – is the ideal solution. Modularity makes anything possible, and both the ON/OFF button and the potentiometer for regulating the air flow can easily be integrated into a panel element or profile. No detailed electrical engineering know-how is needed to install and wire up the parts.

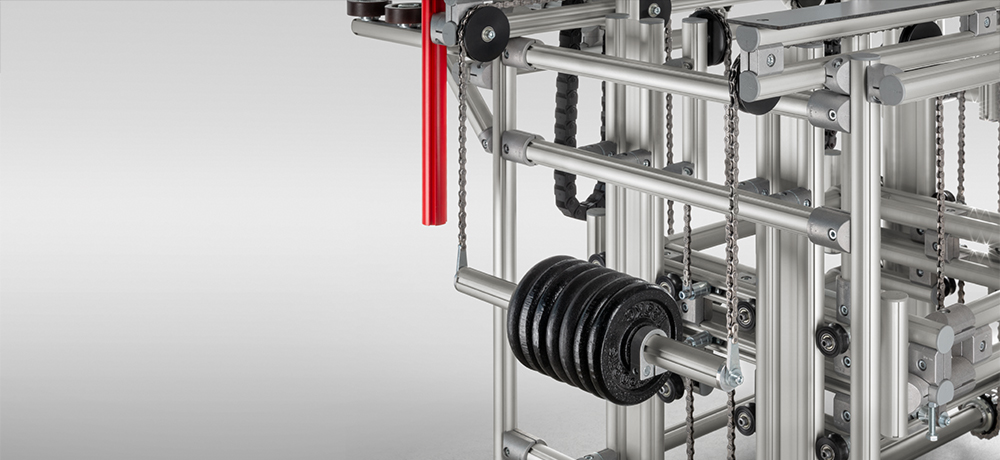

Maximum process reliability with the chain drive for Karakuri/LCA

Karakuri/LCA (low-cost automation) is an alternative form of automation that usually relies on spring force, gravity and lever principles alone. Using a chain in a Karakuri/LCA application, instead of a cable, ensures force can be transmitted to moving parts without the risk of any slippage or elongation. The new item chain drive from the Lean Production Building Kit System is made up of carefully coordinated components for connecting the chain to profiles, redirecting the chain and transmitting forces via a Sprocket Wheel. For example, the pulling of a lever can be converted into a rotational motion. Fitting two Sprocket Wheels side by side also enables users to synchronise two processes.

Design even more applications with the item Engineeringtool

Customer feedback always plays a major role in the development work behind new products from item. The same is true of the latest updates to the item Engineeringtool, which now also allows users to drag and drop solid panel elements into their designs. Even when changing the size of the construction, panels are measured perfectly and fitted in place using the precise number of fastenings. The panel elements available include products made of solid plastic, acrylic glass and polycarbonate, as well as table tops in three different materials. There is now also the option to open preconfigured sample solutions from the Application Gallery directly in the tool and customise them to suit specific requirements. Sample solutions that can be edited in this way are flagged up with a special label.

Discover further new products for autumn in our catalogue

Flexible, reliable and intelligent – the item new products for autumn 2022 solve challenges in the widest range of areas. “New items 2022”, the latest catalogue containing all the autumn product releases, is available as an e-paper in the item Download Center.

Want to keep up to date with everything that’s going on in the world of item? Simply subscribe to the item blog by completing the box at the top right.