Did you know that the inventor of the iPhone also provided a pretty neat description of continuous improvement?

The legendary Steve Jobs still inspires companies worldwide. One little-known but true fact is that he also spoke about the continuous improvement process (CIP) in a video interview. According to Jobs, the view taken by many companies is “that’s the way it’s always been done”. This is the traditional approach. As he saw it, however, modern-day quality thinking calls for a different principle that adopts a scientific attitude towards work processes: “Where there is a theory behind why we do them, there is a description of what we do and, most importantly, there is an opportunity to always question what we do.”

Jobs felt this offers “a tremendous optimistic point of view about the people that work in a company”. The continuous improvement process (CIP) is the key to empowering staff. As Jobs put it: “If given the opportunity to change and improve, they will. They will improve the processes if there’s a mechanism for it. And that optimistic humanism I find very appealing.” The mechanism he is referring to is the continuous improvement process (CIP). Let’s take his inspiring words as the basis for a closer look at CIP.

Lean production – a simple explanation

Find out the best way for your business to get started in lean production. Discover in our free guide which measures are key and learn how to firmly establish the continuous improvement process (CIP) at your company.

DOWNLOAD NOW

Kaizen – a philosophy of small steps and the origin of CIP

The continuous improvement process (CIP) is often regarded as being synonymous with Kaizen. This results in a lot of misunderstandings. Kaizen is an age-old Japanese philosophy for life. It is made up of the Japanese words “Kai” (= change) and “Zen” (= for the better), so Kaizen is all about achieving a change for the better. This traditional concept is based on two assumptions. Firstly, that everything in life can be further improved in small steps. And secondly, that this improvement is continuous. The underlying positive view of the world is that you don’t have to accept inadequate situations but can instead continuously improve them. Toyota recognised the potential of this idea in the 1950s. It became the basis for the Toyota Production System (TPS), which went hand in hand with a positive corporate culture and attitude towards mistakes. A quote from Taiichi Ohno, the man behind the TPS, sums it up perfectly: “Having no problems is the biggest problem of all.” That already says a lot about CIP.

History and definition of CIP

“The Machine That Changed the World: The Story of Lean Production” was published in 1990. It acquainted the Western world with the methods of the Japanese car manufacturer Toyota and is better known simply as the “MIT study”. In this reference book, the three authors describe the method for optimising processes as the continuous improvement process (CIP). Toyota does not use this term. You can therefore clearly see the difference between CIP and Kaizen – the latter extends beyond the world of work and relates to all aspects of life. Kaizen now lives on in the West in the form of CIP, as a kind of Kaizen philosophy for companies. Lean production methods are not confined to industry. Think, for example, of lean management or the lean office. CIP is also an important element of quality management based on DIN EN ISO 9001. Although our focus here is on CIP in lean production, it is also important to be aware of the CIP method’s origins. This is what Jobs meant by “optimistic humanism” – personal development and appreciating staff is what matters.

Continuous improvement is all about making production leaner. The aim is to reduce throughput times.

“Continuous improvement is all about making production leaner. The aim of the improvements is to reduce throughput times. This goes beyond actual production. For example, idle periods during storage or between various processes also need to be factored in. Cutting throughput times has positive effects on your productivity. The two things are closely linked. CIP takes you right to the heart of lean production. “Lean production is the philosophy of continuous improvement,” explains Thomas Hytzki, a lean expert who has worked at item for many years. Reduced throughput times have a whole host of positive effects. “High quality, low costs and excellent flexibility usually follow automatically,” he adds.

Role of staff and equipment in continuous improvement

Staff are at the Gemba (= “actual place”) where value is created. This concept is key when it comes to CIP. It is here that what Jobs described as the “tremendous optimistic point of view” about the people working at a company comes into play. Lean production encourages them to contribute their skills and knowledge. At the same time, they need appropriate structures. A lean and CIP culture creates scope and opportunities for fully realising potential. This lays the foundation for rapid, continuous and flexible improvements. Ideally, staff should have a dedicated CIP workshop. Imagine a checklist – the process, the structures and a dedicated space for CIP are in place. What else does your company still need? That’s right – the appropriate components for lean processes.

You can adapt this factory equipment to suit new requirements and processes at any time. The aluminium that is used is much lighter than steel. At the same time, the long-term stability of your constructions is still ensured.

Our Lean Production Building Kit System has been developed specifically for lean production requirements. The system’s components provide you with the perfect basis for your factory equipment engineering, making it quick and easy to create solutions such as racks and transport trolleys. Profile Tube System D30 is at the heart of our lean system. You can assemble all 90-degree connections on your own – one person, one tool and one type of fastener is all it takes, meaning you save on assembly and storage costs. The modular system and the intuitive fasteners make implementation much simpler. Connections can easily be dismantled again, giving you the flexibility you need for CIP. You can adapt this factory equipment to suit new requirements and processes at any time, resulting in the continuous improvement of material supply and production processes. The aluminium that is used is much lighter than steel. At the same time, the long-term stability of your constructions is still ensured. Would you like to see a few examples? Take a look at our sample solutions here to give you some inspiration.

The 3Ms – challenges in the context of continuous improvement

CIP doesn’t focus on major mistakes. Little details are what matter, with related improvements ultimately achieving great things. Reducing throughput times takes centre stage. High throughput times can largely be attributed to three causes – Muda (waste), Mura (imbalance) and Muri (overloading). Since these causes all start with the same letter, they are called the “3Ms”:

- Muda: This refers to an activity that does not add any value. From the lean production perspective, it amounts to waste and is pointless. There are seven established types of waste in total (= 7 Muda). These range from the unnecessary movement of materials to rejects and reworking. Effective countermeasures exist for all types of Muda.

- Mura: An imbalance exists when resources are not used equally. One workstation has too much to do, while another has little or no work. Queues form upstream of the overworked station, which increases throughput times. What’s more, the underused station creates little added value.

- Muri: A station’s excessive workload can lead to the overloading of staff and equipment alike. The time pressure soon creates physical and psychological stress for personnel. There is also a risk of machinery wearing out, with a particular impact on product quality.

Companies tend to focus more on Muda than on Mura or Muri. This is hardly surprising given that the concept of waste is very easy to grasp. However, the actual source of waste is Mura rather than Muda. Imbalanced processes have further negative consequences. Companies should therefore not just concentrate on Muda.

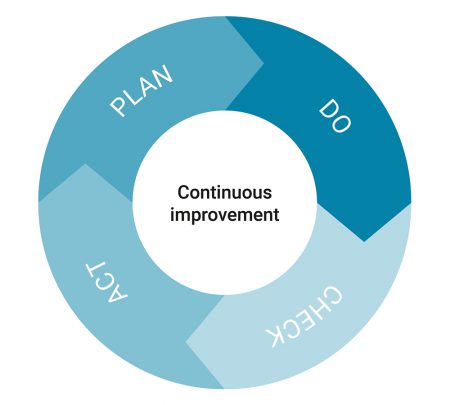

Using the PDCA cycle to implement the continuous improvement process (CIP)

How exactly can you initiate CIP? One of the clearest examples of CIP is the PDCA cycle. It offers you a practical way of implementing CIP. One important thing to note is that lean production is based on the interaction of various methods. For example, goals are defined with the help of value-stream mapping and value-stream design. Only then does the PDCA cycle come into play. The cycle’s name comes from the initial letters of its four steps – “Plan”, “Do”, “Check” and “Act”. You should define just one measure for each PDCA cycle. The process and steps are always the same:

Plan:

Observe the processes and the actual situation on site. It is essential that you speak directly to staff. Identify processes that are in need of improvement and develop a plan. The aim is to initiate continuous improvement. Collect data, facts and figures as a basis for defining the measure to achieve the target situation.

Do:

PDCA is all about trying out things on a small scale. Apply your idea in a practical experiment. Trying out just one measure makes the relationship between cause and effect transparent. If something doesn’t work, there are no major consequences. That’s the advantage of little experiments of this kind.

Check:

The next step is an evaluation. Analyse all the measures you have taken. What was successful and what wasn’t? What were the reasons for the success or failure? Could a particular strategy conceivably be applied throughout the entire company? Only at this stage should you consider the big picture.

Act:

You can now take more extensive measures, which you should document and verify. Other possibilities include holding workshops or purchasing new equipment. If your measures are successful, you should introduce them as standard. Otherwise, the PDCA process starts over.

PDCA clearly illustrates the essence of CIP. You can see how it is directly related to the words of Steve Jobs about the scientific nature of the method. There is a theory behind the measures, they are described in detail and they can be questioned. Let’s round things off by hearing exactly what the man himself had to say. We have thus come full circle – just like CIP!

Are you interested in fascinating reports and innovations from the world of lean production? Then we have just what you’re looking for! Simply subscribe to the item blog by completing the box at the top right.