Christmas is approaching and the new year is just around the corner. This can only mean one thing – it’s time for us to look back at the best topics and most inspiring projects from our blog posts in 2022!

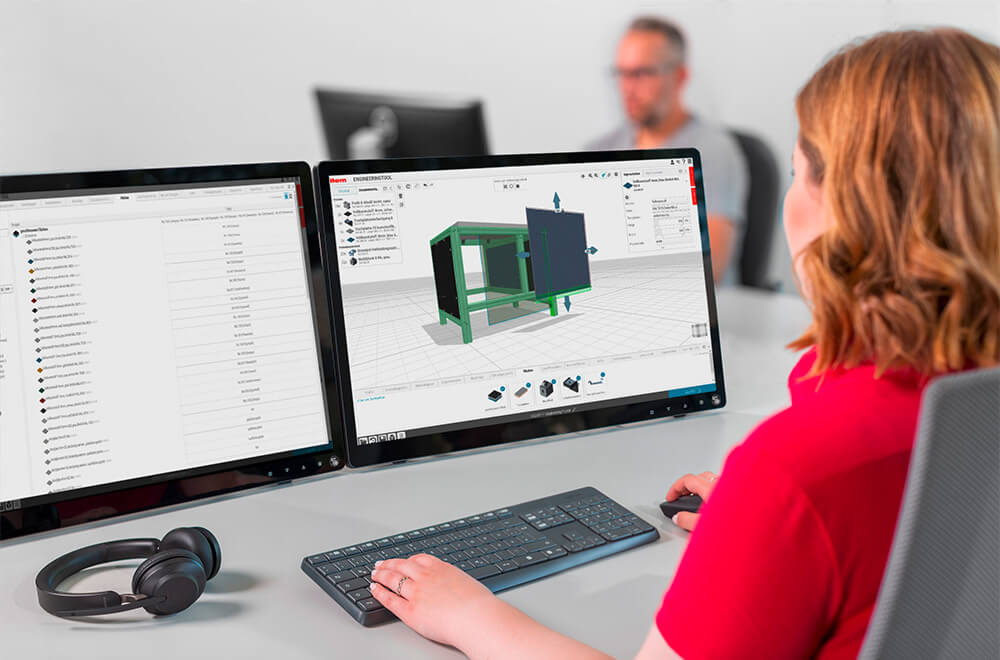

What began in late 2021 continued seamlessly into the new year, with the item blog covering the advantages and possibilities of robotics applications in detail. There were posts on an extremely broad range of topics, covering everything from the history of robotics, the free robotics training offered in the item Academy and simple robot programming, right through to a comparison of automated guided vehicles (AGVs) and autonomous mobile robots (AMRs). We also showcased in-house projects, such as the structure for a robot with a seventh axis (from Universal Robots or ABB) and an AMR project for optimising intralogistics. Of course, there was no shortage of posts on digitalisation in general in 2022, either. For instance, we showcased the advantages of digitalisation for companies and major future trends for industry. A particular highlight was our post on the expansion of the item Engineeringtool to include solid panel elements.

Geared towards lean production and ergonomics from head to toe

Right from the very start, lean production and ergonomic work bench design have been some of the most popular topics on the item blog. So what better way to kick off 2022? Our first blog post of the year was a presentation of typical examples of CIP – including the lean method of Karakuri/LCA (= low-cost automation), which was proved to be highly cost-effective in a practical test conducted by NORDAKADEMIE. At the beginning of the year, ergonomics enthusiasts got to enjoy the case study of SIKO GmbH, which is using around 100 ergonomic work benches from item at a new location. The MTM method was used when planning the assembly concept for these work benches, which we later discussed in an interview with Dr. Steffen Rast from Deutsche MTM-Gesellschaft Industrie- und Wirtschaftsberatung mbH.

Bringing movement into production with item

The MTM method is all about assessing current and future manual activities. Needless to say, movement plays a crucial role in this. To highlight the many ways the item modular concept can benefit movement in general and material flow in particular, we’ve been marking posts on these topics – both old and new – with special tags on the item blog since autumn 2022. The motto of this campaign is “item in motion” – and the name says it all. For this reason, selected posts in the fourth quarter were all about dynamism and the joy of movement. These included a comparison of robotics and linear technology and an insight into the work of Professor Constantin May, founder and academic director of the CETPM training institute. The lean expert combines Karakuri/LCA with AMRs and cobots, which is a particularly promising prospect for industry in times of soaring energy costs.

A look behind the scenes and new product highlights

Design has been a top priority at item ever since it was founded. In an interview, product designer Carsten Schulz talks to us about his design team’s award-winning work. All products are developed in collaboration with the design team to ensure that everything fits into the item design philosophy. Needless to say, this was also the case for the new products launched in spring and autumn 2022, the highlights of which we showcased on the item blog. We were also able to unveil two new product ranges this year. One of these was the item Conveyor Belt System, which maximizes flexibility for solutions for transporting production parts or small load carriers. When it comes to the medical or pharmaceutical sector, item solutions for clean production are particularly relevant, with the portfolio ranging from machine cabins with integrated Filter Fan Units and air recirculation to work benches for cleanroom production.

Profile technology proves its versatility once again

In 2022, we got to report on many inspiring applications, including the youth training programme at the Hagen Technology Centre, which now has a mobile machine table at its disposal, featuring profiles from the item MB Building Kit System and an enclosed milling machine on top. This kind of equipment is helping the extracurricular learning space inspire enthusiasm for the world of engineering. All in all, robots played a big part, underlining yet again their growing importance for the future of industry. For example, GRIP GmbH Handhabungstechnik from the item pluspartner network has developed a particularly versatile and ergonomic robot table using components from the item building kit system for cobot solutions. Not only that, but the special GRIP Auto Connector helps reduce changeover times – in keeping with the SMED (Single Minute Exchange of Die) lean method. Incidentally, a dedicated online training course on SMED is now available in the item Academy. All you need to access this course directly is a free item user account.

The Vensys robot and automation solutions benefit from a safe, flexible and stable machine cabin based on Line XMS.

Readers interested in the superstructures used for AMRs in the item European logistics headquarters will likely be similarly drawn to the mobile-robot-based automation that Lenkering Montage- und Zerspanungstechnik GmbH (LMZ) has added to its service portfolio. The way the item pluspartner optimised its own intralogistics by combining an AMR from OMRON and an item-based superstructure made for a perfect use case. The results were truly astounding, saving the company 170 minutes per day. The item blog took a trip to Italy for a post on the robot and automation solutions for the automotive industry developed by Vensys. This post specifically looks at a robot soldering station and a machine for assembling and testing electronic flasher units. Both projects benefit from a safe, flexible and stable machine cabin based on Line XMS.

We hope that we were able to inform, entertain and inspire you again this year and wish you a merry Christmas and a wonderful start to 2023! After a short Christmas break, the item blog will be back with new posts on 11 January.